Low-melting-point tin alloys offer superior fluidity and faster melting, making them ideal for applications requiring quick casting and easy mold filling. High-melting-point tin alloys provide enhanced mechanical strength and thermal stability, suitable for components exposed to elevated temperatures. Selecting the appropriate tin alloy depends on balancing processing efficiency with the operational requirements of the final product.

Table of Comparison

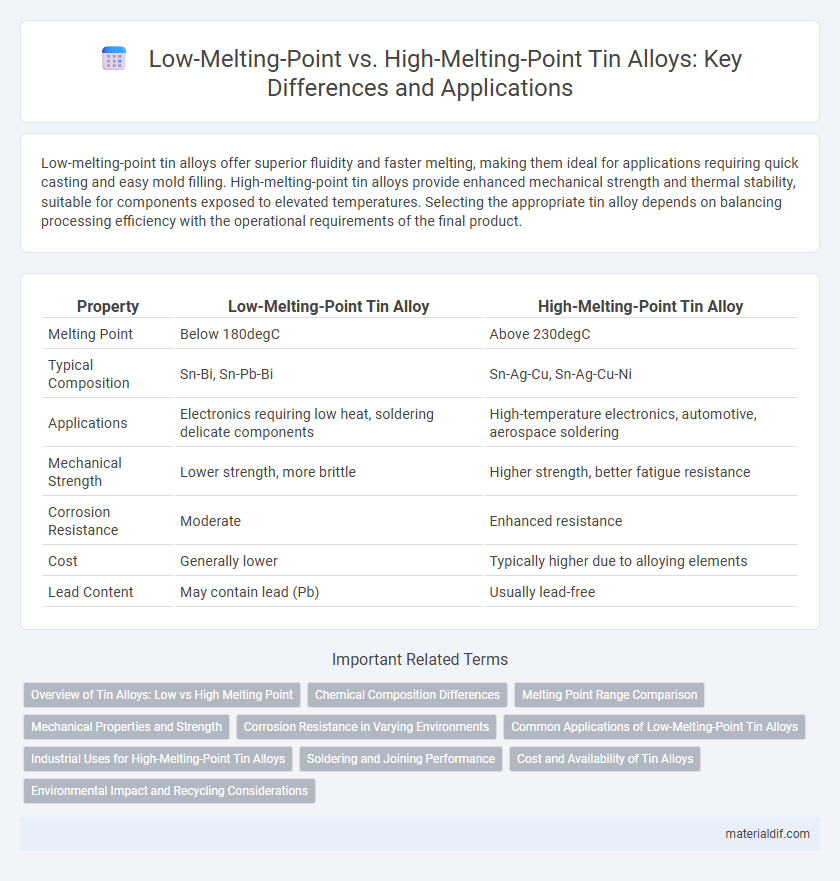

| Property | Low-Melting-Point Tin Alloy | High-Melting-Point Tin Alloy |

|---|---|---|

| Melting Point | Below 180degC | Above 230degC |

| Typical Composition | Sn-Bi, Sn-Pb-Bi | Sn-Ag-Cu, Sn-Ag-Cu-Ni |

| Applications | Electronics requiring low heat, soldering delicate components | High-temperature electronics, automotive, aerospace soldering |

| Mechanical Strength | Lower strength, more brittle | Higher strength, better fatigue resistance |

| Corrosion Resistance | Moderate | Enhanced resistance |

| Cost | Generally lower | Typically higher due to alloying elements |

| Lead Content | May contain lead (Pb) | Usually lead-free |

Overview of Tin Alloys: Low vs High Melting Point

Low-melting-point tin alloys, such as those containing bismuth, lead, or indium, typically melt below 200degC and are widely used in soldering applications due to their excellent wetting properties and ease of alloying. High-melting-point tin alloys include compositions with silver, copper, or antimony, which exhibit melting points above 200degC and are preferred for durable components requiring enhanced mechanical strength and thermal stability. The distinct melting ranges influence their selection across electronics, automotive, and aerospace industries, balancing factors like joint reliability, thermal conductivity, and environmental compliance.

Chemical Composition Differences

Low-melting-point tin alloys typically contain higher proportions of bismuth, lead, or indium, which lower the melting temperature to around 100-150degC, ideal for soldering and low-heat applications. High-melting-point tin alloys include greater amounts of silver, copper, and antimony, raising the melting temperature above 200degC for enhanced mechanical strength and thermal stability. The distinct chemical compositions directly influence melting points, mechanical properties, and application suitability across electronics, plumbing, and industrial fabrication.

Melting Point Range Comparison

Low-melting-point tin alloys typically have melting points between 90degC and 200degC, making them ideal for applications requiring quick and energy-efficient melting processes. High-melting-point tin alloys exhibit melting ranges above 200degC, often reaching up to 300degC, which provides enhanced mechanical strength and thermal stability for demanding industrial uses. Comparing the melting point ranges highlights the trade-off between ease of melting and performance durability depending on the alloy composition.

Mechanical Properties and Strength

Low-melting-point tin alloys exhibit enhanced ductility and ease of machining due to their softer microstructure, but they generally possess lower tensile strength and hardness compared to high-melting-point tin alloys. High-melting-point tin alloys demonstrate superior mechanical strength, greater wear resistance, and improved dimensional stability at elevated temperatures, making them suitable for applications requiring durability under stress. The choice between these alloys hinges on balancing the need for mechanical robustness versus ease of processing and application-specific thermal requirements.

Corrosion Resistance in Varying Environments

Low-melting-point tin alloys typically exhibit enhanced corrosion resistance in mildly aggressive environments due to their finer microstructure and lower melting temperature, which reduces thermal stress-induced defects. High-melting-point tin alloys maintain superior corrosion resistance in harsh or high-temperature corrosive conditions, owing to their stable phase composition and robust intermetallic compound formation. Selecting the appropriate tin alloy depends on balancing corrosion resistance requirements with environmental factors such as temperature, moisture, and chemical exposure.

Common Applications of Low-Melting-Point Tin Alloys

Low-melting-point tin alloys are commonly used in soldering applications for electronics, where they provide reliable electrical connections at lower temperatures, minimizing damage to sensitive components. These alloys are also essential in manufacturing fusible plugs and fire safety devices due to their precise melting points that trigger safety mechanisms. Furthermore, low-melting-point tin alloys find application in metal casting for rapid prototyping and creating detailed molds because they melt easily and solidify quickly.

Industrial Uses for High-Melting-Point Tin Alloys

High-melting-point tin alloys, characterized by melting points above 300degC, are essential in industrial applications requiring thermal stability and mechanical strength, such as in aerospace components, electronic soldering for high-temperature circuits, and automotive engine parts. These alloys maintain structural integrity under extreme heat, providing corrosion resistance and enhanced durability in harsh environments. Their composition often includes elements like copper, nickel, and antimony, optimizing performance for demanding manufacturing processes.

Soldering and Joining Performance

Low-melting-point tin alloys, typically containing bismuth or indium, offer superior soldering performance due to lower melting temperatures around 138-183degC, which minimizes thermal damage to sensitive components during joining processes. High-melting-point tin alloys, often alloyed with copper or silver, melt above 230degC and provide enhanced mechanical strength and thermal stability for joints in demanding applications. The choice between these alloys depends on the balance between solderability, joint reliability, and the operating environment of the electronic or mechanical assembly.

Cost and Availability of Tin Alloys

Low-melting-point tin alloys generally cost more due to the inclusion of rare metals like bismuth or indium, which improve melting characteristics but increase overall expense. High-melting-point tin alloys primarily use more abundant tin and lead, making them more affordable and widely available for industrial applications. Availability of base metals significantly influences production costs, with low-melting-point alloys often limited by the scarcity and higher prices of alloying elements.

Environmental Impact and Recycling Considerations

Low-melting-point tin alloys typically contain elements like bismuth and lead, which can pose significant environmental hazards due to their toxicity and difficulty in recycling. High-melting-point tin alloys are often composed of purer tin or combined with non-toxic metals, resulting in more environmentally friendly disposal and easier recycling processes. Recycling high-melting-point tin alloys reduces energy consumption and minimizes hazardous waste, making them preferable for sustainable manufacturing practices.

Low-melting-point tin alloy vs High-melting-point tin alloy Infographic

materialdif.com

materialdif.com