A steel base offers superior durability and corrosion resistance compared to an iron base, making it ideal for long-lasting tin pet containers. Steel's strength ensures better protection against deformation and wear during transportation and storage. Iron bases, while cost-effective, are more prone to rust and damage over time, reducing the overall lifespan of the tin pet.

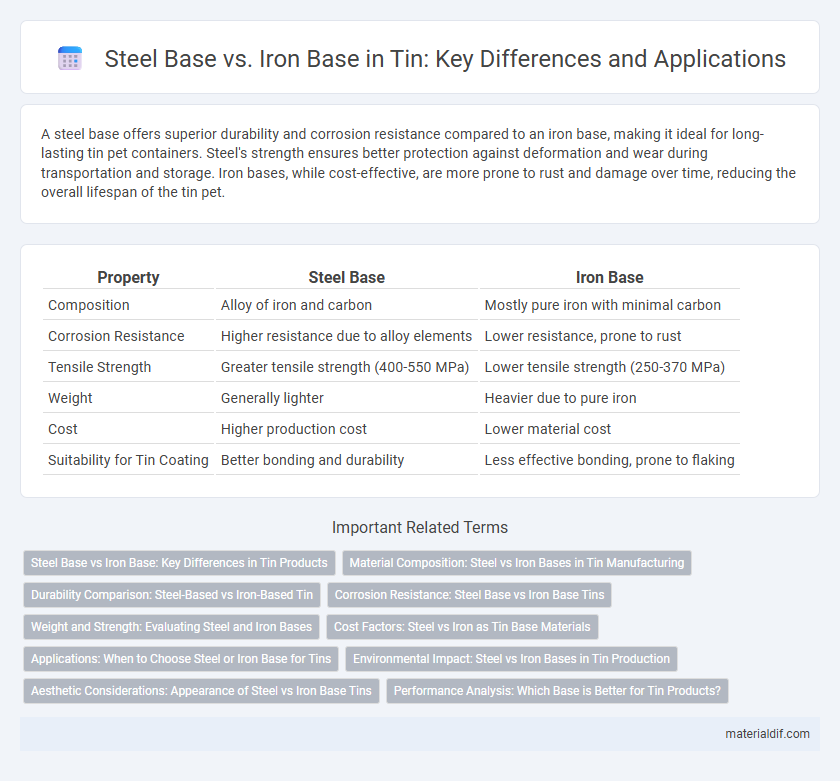

Table of Comparison

| Property | Steel Base | Iron Base |

|---|---|---|

| Composition | Alloy of iron and carbon | Mostly pure iron with minimal carbon |

| Corrosion Resistance | Higher resistance due to alloy elements | Lower resistance, prone to rust |

| Tensile Strength | Greater tensile strength (400-550 MPa) | Lower tensile strength (250-370 MPa) |

| Weight | Generally lighter | Heavier due to pure iron |

| Cost | Higher production cost | Lower material cost |

| Suitability for Tin Coating | Better bonding and durability | Less effective bonding, prone to flaking |

Steel Base vs Iron Base: Key Differences in Tin Products

Steel-based tin products offer superior strength and corrosion resistance compared to iron-based tin, making them ideal for long-lasting applications. Iron-based tin products are more prone to rust and wear, which limits their durability in harsh environments. The enhanced mechanical properties and improved longevity of steel-based tins make them a preferred choice in packaging and industrial uses.

Material Composition: Steel vs Iron Bases in Tin Manufacturing

Steel bases in tin manufacturing primarily consist of iron alloyed with carbon and trace elements such as manganese and chromium, enhancing strength and corrosion resistance. Iron bases are predominantly pure iron, offering higher malleability but lower durability and susceptibility to rust. The choice between steel and iron bases directly impacts the tin product's mechanical properties, lifespan, and suitability for various industrial applications.

Durability Comparison: Steel-Based vs Iron-Based Tin

Steel-based tin offers superior durability due to the alloy's higher tensile strength and resistance to corrosion compared to iron-based tin. The presence of carbon in steel enhances hardness and wear resistance, making steel-based tin ideal for applications requiring long-lasting performance. Iron-based tin tends to be more prone to rust and mechanical wear, reducing its effectiveness in harsh environments.

Corrosion Resistance: Steel Base vs Iron Base Tins

Steel base tins exhibit superior corrosion resistance compared to iron base tins due to the chromium content in steel that forms a protective oxide layer. Iron base tins lack this chromium layer, making them more susceptible to rust and corrosion over time in humid or acidic environments. This enhanced corrosion resistance makes steel base tins more suitable for long-term storage and packaging in industries prone to moisture exposure.

Weight and Strength: Evaluating Steel and Iron Bases

Steel bases exhibit higher tensile strength and durability compared to iron bases, making them preferable for applications requiring robust support and longevity. Despite being heavier than iron, steel's alloy composition enhances its overall structural integrity without compromising stability. Iron bases, while lighter, tend to offer less resistance to wear and corrosion, impacting their suitability for weight-bearing or high-stress environments.

Cost Factors: Steel vs Iron as Tin Base Materials

Steel-based tin bases generally incur higher costs due to more complex alloying and manufacturing processes, which enhance durability and corrosion resistance compared to iron bases. Iron-based tin bases offer lower material expenses but tend to require more frequent maintenance or replacement, driving long-term costs upward. Cost-effectiveness depends on application needs, with steel preferred for high-performance environments and iron for budget-sensitive projects.

Applications: When to Choose Steel or Iron Base for Tins

Steel base tins are preferred for food and beverage packaging due to their corrosion resistance and strength, ensuring product safety and durability. Iron base tins are often chosen for industrial applications where cost-efficiency is critical, but they require protective coatings to prevent rust. Selecting between steel or iron bases depends on the need for longevity, exposure to moisture, and regulatory food safety standards.

Environmental Impact: Steel vs Iron Bases in Tin Production

Steel bases in tin production offer a more sustainable option compared to iron bases due to lower greenhouse gas emissions during manufacturing. The recycling rate of steel exceeds 90%, significantly reducing landfill waste and conserving natural resources, whereas iron base processes often involve higher energy consumption and raw material extraction. Life cycle assessments indicate steel bases generate fewer pollutants and support circular economy principles more effectively than iron bases in tin extraction and refining.

Aesthetic Considerations: Appearance of Steel vs Iron Base Tins

Steel base tins offer a smooth, shiny finish that enhances visual appeal and provides a modern, sleek look, making them ideal for premium packaging. Iron base tins typically have a matte or slightly rougher surface that conveys a more rustic, vintage aesthetic, appealing to brands targeting traditional or artisanal markets. Corrosion resistance in steel base tins maintains their aesthetic integrity longer compared to iron base tins, which may develop rust spots affecting overall appearance.

Performance Analysis: Which Base is Better for Tin Products?

Steel base offers higher strength and corrosion resistance compared to iron base in tin product manufacturing, resulting in enhanced durability and longevity. Iron base provides superior thermal conductivity, which benefits specific tin applications requiring rapid heat dissipation. Performance analysis indicates steel base is generally better for heavy-duty tin products, while iron base suits applications emphasizing efficient heat transfer.

Steel Base vs Iron Base Infographic

materialdif.com

materialdif.com