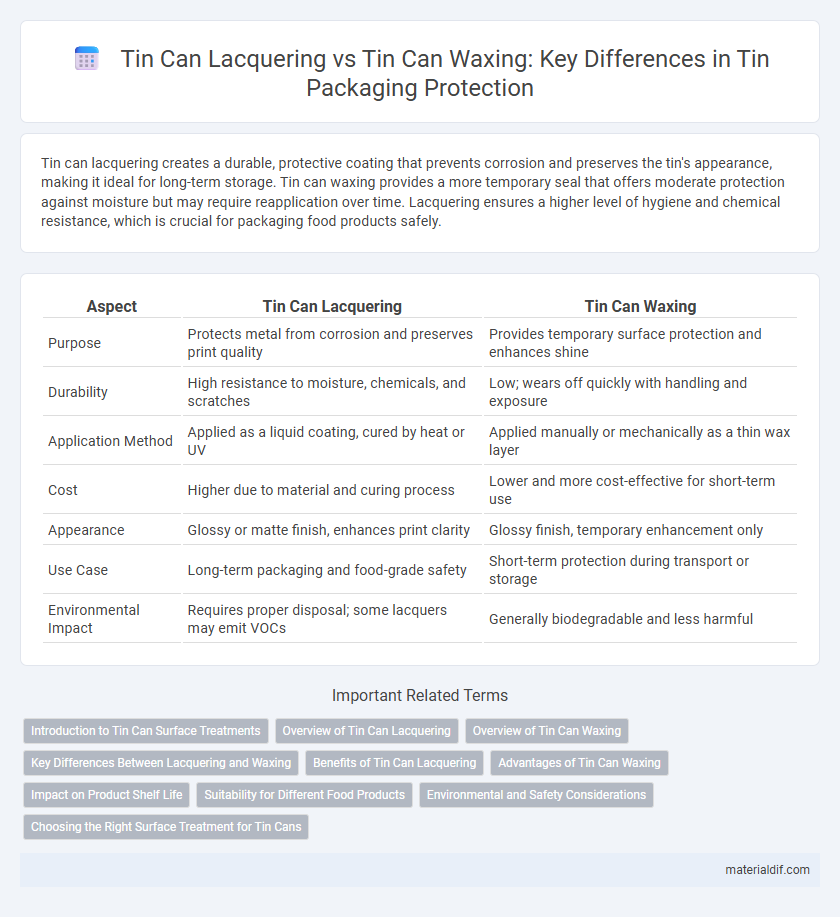

Tin can lacquering creates a durable, protective coating that prevents corrosion and preserves the tin's appearance, making it ideal for long-term storage. Tin can waxing provides a more temporary seal that offers moderate protection against moisture but may require reapplication over time. Lacquering ensures a higher level of hygiene and chemical resistance, which is crucial for packaging food products safely.

Table of Comparison

| Aspect | Tin Can Lacquering | Tin Can Waxing |

|---|---|---|

| Purpose | Protects metal from corrosion and preserves print quality | Provides temporary surface protection and enhances shine |

| Durability | High resistance to moisture, chemicals, and scratches | Low; wears off quickly with handling and exposure |

| Application Method | Applied as a liquid coating, cured by heat or UV | Applied manually or mechanically as a thin wax layer |

| Cost | Higher due to material and curing process | Lower and more cost-effective for short-term use |

| Appearance | Glossy or matte finish, enhances print clarity | Glossy finish, temporary enhancement only |

| Use Case | Long-term packaging and food-grade safety | Short-term protection during transport or storage |

| Environmental Impact | Requires proper disposal; some lacquers may emit VOCs | Generally biodegradable and less harmful |

Introduction to Tin Can Surface Treatments

Tin can surface treatments primarily involve lacquering and waxing to enhance corrosion resistance and preserve the metal's integrity. Lacquering applies a durable, clear coating that adheres directly to the tin surface, offering long-term protection against moisture and contamination. Waxing, by contrast, provides a temporary barrier that can be easily removed, suitable for short-term protection during storage or handling of tin cans.

Overview of Tin Can Lacquering

Tin can lacquering involves applying a protective coating inside the can to prevent corrosion and preserve the product's flavor and shelf life, making it essential for food and beverage packaging. This coating is typically made from epoxy or polymer-based materials that create a barrier against acidic or oily contents. Lacquering enhances the durability and safety of tin cans compared to waxing, which primarily serves as a simpler moisture barrier and offers less chemical resistance.

Overview of Tin Can Waxing

Tin can waxing creates a protective layer that enhances corrosion resistance and preserves the can's surface without altering its appearance. This method is cost-effective and involves applying a thin wax coating that prevents moisture and oxygen from reaching the metal. Waxing is ideal for cans storing dry goods, offering a flexible barrier compared to the rigid lacquer finish used in other tin can treatments.

Key Differences Between Lacquering and Waxing

Tin can lacquering involves applying a durable, protective coating that enhances corrosion resistance and preserves the can's appearance, while tin can waxing uses a thin layer of wax primarily to prevent surface friction and minor tarnish. Lacquering provides a more robust barrier against moisture and chemical reactions, making it suitable for long-term storage and food safety. Waxing is generally easier to apply and remove but offers less protection compared to lacquering, making it ideal for short-term use or decorative purposes.

Benefits of Tin Can Lacquering

Tin can lacquering provides superior corrosion resistance compared to waxing, effectively protecting the metal from acidic or moisture-rich contents, which extends shelf life and maintains product integrity. The lacquer forms a durable, chemically resistant barrier that prevents metal contamination and preserves the container's aesthetic appeal. This coating also enhances food safety by preventing interaction between the tin and the can's contents, making it ideal for long-term storage applications.

Advantages of Tin Can Waxing

Tin can waxing offers superior moisture resistance and enhanced corrosion protection compared to lacquering, extending the shelf life of canned products. The wax coating provides a flexible, non-toxic barrier that maintains the integrity of the metal without cracking or peeling over time. Its environmentally friendly application process reduces the use of harmful chemicals, making tin can waxing a sustainable choice for food packaging.

Impact on Product Shelf Life

Tin can lacquering provides a protective barrier that significantly enhances the product's shelf life by preventing chemical reactions and corrosion caused by food acids and moisture. Waxing, while offering some surface protection, is less effective in maintaining product integrity over time due to its lower resistance to environmental factors. As a result, lacquered tin cans are preferred for extending shelf life and preserving food quality.

Suitability for Different Food Products

Tin can lacquering provides a durable, food-safe coating ideal for acidic and high-moisture foods such as tomatoes and fruits, preventing metal contamination and preserving flavor. Waxing suits dry or low-moisture products like nuts and candy, offering a protective layer that maintains freshness without reacting with the contents. Selecting between lacquering and waxing depends largely on the food's moisture content and acidity to ensure optimal preservation and safety.

Environmental and Safety Considerations

Tin can lacquering uses chemical coatings that may release volatile organic compounds (VOCs), posing environmental and health hazards during application and disposal. In contrast, tin can waxing involves natural waxes with lower toxicity and reduced environmental impact, offering safer handling and easier recyclability. Evaluating the trade-offs, waxing presents a greener alternative, while lacquering ensures longer corrosion resistance but requires stringent safety protocols.

Choosing the Right Surface Treatment for Tin Cans

Selecting the right surface treatment for tin cans involves weighing the benefits of lacquering against waxing. Lacquering provides a durable, protective coating that resists corrosion and maintains the can's appearance during long-term storage, making it ideal for food packaging. Waxing, while offering a more flexible and eco-friendly option, is better suited for short-term product protection due to its lower resistance to moisture and abrasion.

Tin can lacquering vs Tin can waxing Infographic

materialdif.com

materialdif.com