Reflowed tin coating provides a smoother, more uniform surface that enhances solderability and reduces the risk of oxidation compared to non-reflowed tin coating. The reflow process melts the tin layer, improving adhesion and creating a robust metallurgical bond for reliable electrical connections. Non-reflowed tin coatings often have uneven textures and higher surface oxides, which can compromise component performance and lifespan.

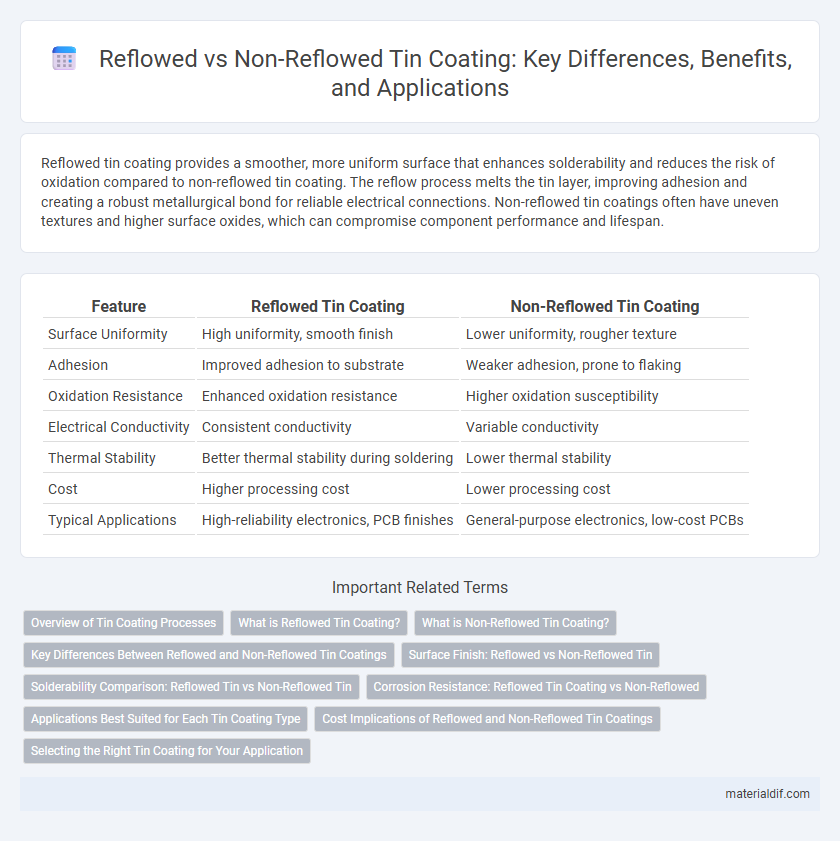

Table of Comparison

| Feature | Reflowed Tin Coating | Non-Reflowed Tin Coating |

|---|---|---|

| Surface Uniformity | High uniformity, smooth finish | Lower uniformity, rougher texture |

| Adhesion | Improved adhesion to substrate | Weaker adhesion, prone to flaking |

| Oxidation Resistance | Enhanced oxidation resistance | Higher oxidation susceptibility |

| Electrical Conductivity | Consistent conductivity | Variable conductivity |

| Thermal Stability | Better thermal stability during soldering | Lower thermal stability |

| Cost | Higher processing cost | Lower processing cost |

| Typical Applications | High-reliability electronics, PCB finishes | General-purpose electronics, low-cost PCBs |

Overview of Tin Coating Processes

Reflowed tin coating involves heating the tin deposit above its melting point to create a smooth, uniform surface that enhances solderability and reduces surface defects. Non-reflowed tin coating applies tin at lower temperatures without remelting, resulting in a rougher finish that may contain burrs or oxide inclusions. The reflow process improves coating integrity and electrical performance in electronic components compared to non-reflow methods.

What is Reflowed Tin Coating?

Reflowed tin coating involves melting the tin layer after application to create a smooth, uniform surface, enhancing solderability and reducing whisker growth. This process improves the adhesion and reliability of electronic components by eliminating roughness and irregularities present in non-reflowed tin coatings. Compared to non-reflowed tin, reflowed tin provides superior mechanical and electrical performance in printed circuit boards (PCBs).

What is Non-Reflowed Tin Coating?

Non-reflowed tin coating refers to a type of surface finish applied to electronic components or circuit boards where the tin layer is deposited but does not undergo a subsequent reflow soldering process to melt and solidify the coating. This results in a matte, loosely adhered tin layer that tends to have higher porosity and lower solderability compared to reflowed tin coatings. Non-reflowed tin coatings are more prone to whisker growth and may have reduced corrosion resistance, impacting long-term reliability in electronic assemblies.

Key Differences Between Reflowed and Non-Reflowed Tin Coatings

Reflowed tin coatings exhibit a smooth, uniform surface achieved by melting and solidifying the tin layer, enhancing solderability and reducing whisker growth compared to non-reflowed tin coatings, which remain rough and grainy with higher risks of poor adhesion and electrical reliability issues. Reflowing improves the inter-metallic bond between the tin and substrate, resulting in superior mechanical strength and corrosion resistance, whereas non-reflowed coatings show weaker bonding and increased susceptibility to oxidation. The controlled microstructure of reflowed tin significantly minimizes the formation of tin whiskers, crucial for applications in aerospace and electronics where long-term performance is critical.

Surface Finish: Reflowed vs Non-Reflowed Tin

Reflowed tin coating offers a smoother and more uniform surface finish compared to non-reflowed tin coating, reducing surface roughness and improving solderability. The reflow process minimizes the presence of oxides and contaminants, enhancing the wetting properties essential for reliable electrical connections. Non-reflowed tin coatings often exhibit a grainier texture and higher levels of surface impurities, which can compromise joint integrity and increase the risk of corrosion.

Solderability Comparison: Reflowed Tin vs Non-Reflowed Tin

Reflowed tin coatings exhibit superior solderability compared to non-reflowed tin due to their enhanced surface uniformity and reduced oxides, which promote better wetting and stronger metallurgical bonds with solder alloys. In contrast, non-reflowed tin coatings often contain irregular crystalline structures and higher levels of surface oxidation, leading to increased soldering defects and weaker joint reliability. Studies show reflowed tin can reduce solder joint voids by up to 30% and improve wetting angles by approximately 20 degrees, making it the preferred choice for high-reliability electronic assemblies.

Corrosion Resistance: Reflowed Tin Coating vs Non-Reflowed

Reflowed tin coatings exhibit superior corrosion resistance compared to non-reflowed tin due to their uniform, dense microstructure that minimizes porosity and oxidation pathways. The reflow process enhances adhesion and reduces surface defects, resulting in a more stable barrier against environmental factors such as moisture and oxidation. Non-reflowed tin coatings often show increased susceptibility to corrosion, as irregular deposition and higher porosity facilitate accelerated degradation.

Applications Best Suited for Each Tin Coating Type

Reflowed tin coating offers superior solderability and reduced whisker growth, making it ideal for high-reliability electronics, such as automotive and aerospace components. Non-reflowed tin coating, with its simpler application and lower cost, suits less demanding applications like consumer electronics and general-purpose printed circuit boards. Selecting between these coatings depends on the need for mechanical strength, environmental resistance, and long-term performance in specific industrial sectors.

Cost Implications of Reflowed and Non-Reflowed Tin Coatings

Reflowed tin coatings generally incur higher costs due to the additional thermal processing required to achieve uniform thickness and enhanced adhesion on PCB surfaces. Non-reflowed tin coatings reduce manufacturing expenses by eliminating the reflow step but may lead to increased failure rates and higher long-term maintenance costs due to poorer coating quality. Cost implications must balance upfront savings against potential reliability issues associated with non-reflowed tin coatings in electronic assemblies.

Selecting the Right Tin Coating for Your Application

Choosing between reflowed and non-reflowed tin coatings depends on factors like desired surface uniformity, solderability, and environmental conditions. Reflowed tin coatings offer smoother, more consistent layers with improved solder joint reliability, ideal for high-precision electronics exposed to thermal cycling. Non-reflowed tin coatings provide a less processed surface that might be suitable for applications with lower thermal stress or cost-sensitive projects where advanced soldering performance is not critical.

Reflowed tin coating vs Non-reflowed tin coating Infographic

materialdif.com

materialdif.com