Sn-Pb alloy has been widely used for its excellent solderability and low melting point, making it ideal for traditional electronic assembly, but concerns about toxicity and environmental impact have driven the shift towards lead-free alternatives. Sn-Ag-Cu alloy offers enhanced mechanical strength, better thermal fatigue resistance, and improved environmental safety by eliminating lead content, making it the preferred choice in modern electronics. While Sn-Pb provides ease of processing, Sn-Ag-Cu's superior reliability and compliance with RoHS regulations position it as the future standard in solder materials.

Table of Comparison

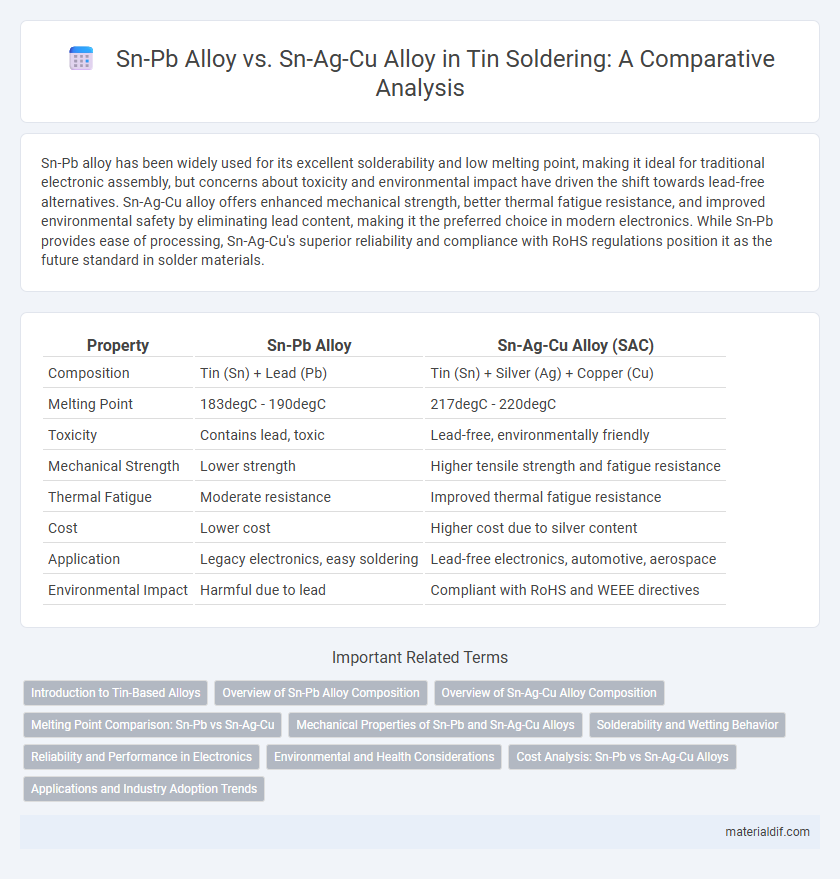

| Property | Sn-Pb Alloy | Sn-Ag-Cu Alloy (SAC) |

|---|---|---|

| Composition | Tin (Sn) + Lead (Pb) | Tin (Sn) + Silver (Ag) + Copper (Cu) |

| Melting Point | 183degC - 190degC | 217degC - 220degC |

| Toxicity | Contains lead, toxic | Lead-free, environmentally friendly |

| Mechanical Strength | Lower strength | Higher tensile strength and fatigue resistance |

| Thermal Fatigue | Moderate resistance | Improved thermal fatigue resistance |

| Cost | Lower cost | Higher cost due to silver content |

| Application | Legacy electronics, easy soldering | Lead-free electronics, automotive, aerospace |

| Environmental Impact | Harmful due to lead | Compliant with RoHS and WEEE directives |

Introduction to Tin-Based Alloys

Tin-based alloys such as Sn-Pb (tin-lead) and Sn-Ag-Cu (tin-silver-copper) are widely used in soldering applications due to their excellent metallurgical properties. The Sn-Pb alloy, traditionally favored for its low melting point and good mechanical strength, is being phased out because of environmental and health concerns related to lead. Sn-Ag-Cu alloys, often referred to as SAC alloys, provide a lead-free alternative with superior thermal fatigue resistance and mechanical reliability, making them ideal for modern electronic assemblies.

Overview of Sn-Pb Alloy Composition

Sn-Pb alloy typically consists of approximately 60-63% tin (Sn) and 37-40% lead (Pb), optimizing its melting point for soldering applications. This eutectic composition, commonly 63% Sn and 37% Pb, melts sharply at 183degC, enhancing flow and wetting properties crucial in electronics manufacturing. The alloy's reliability and ease of use have historically made it a standard, despite environmental restrictions promoting lead-free alternatives like Sn-Ag-Cu alloys.

Overview of Sn-Ag-Cu Alloy Composition

The Sn-Ag-Cu alloy primarily consists of about 96.5% tin, 3.0% silver, and 0.5% copper, offering improved mechanical strength and thermal fatigue resistance compared to traditional Sn-Pb alloys. This lead-free composition enhances solder joint reliability in electronic assemblies, especially under high-temperature cycling conditions. The microstructure formed by silver and copper precipitates increases creep resistance and prevents tin whisker growth, making it a preferred choice for modern electronics.

Melting Point Comparison: Sn-Pb vs Sn-Ag-Cu

The Sn-Pb alloy typically melts around 183degC, offering a lower melting point ideal for traditional soldering applications. In contrast, the Sn-Ag-Cu (SAC) alloy melts at a higher temperature range of approximately 217-220degC, providing enhanced thermal stability and mechanical strength. This difference significantly affects the choice of alloy in electronics manufacturing, balancing between ease of melting and durability under thermal stress.

Mechanical Properties of Sn-Pb and Sn-Ag-Cu Alloys

Sn-Pb alloys exhibit exceptional ductility and fatigue resistance, making them highly effective in absorbing mechanical stress and providing reliable long-term performance in electronic soldering applications. Sn-Ag-Cu (SAC) alloys offer higher tensile strength and better creep resistance compared to Sn-Pb, enhancing durability under elevated temperatures and mechanical loads. The inherent mechanical robustness of SAC alloys supports their widespread adoption in lead-free soldering to meet environmental regulations without compromising joint integrity.

Solderability and Wetting Behavior

Sn-Pb alloys exhibit excellent solderability and superior wetting behavior due to their low melting point and stable intermetallic compound formation, facilitating strong joint strength. Sn-Ag-Cu (SAC) alloys offer enhanced mechanical properties and environmental compliance, though their solderability can be slightly lower, requiring optimized flux and thermal profiles to improve wetting angles. The SAC alloy's wetting speed and spread are influenced by Ag and Cu content, which modify surface tension and interfacial energy, affecting the formation of wetting fillets on copper substrates.

Reliability and Performance in Electronics

Sn-Ag-Cu alloy demonstrates superior reliability and performance in electronics compared to Sn-Pb alloy due to its higher melting point and better mechanical strength, which enhances solder joint durability under thermal cycling. Sn-Ag-Cu's improved wetting properties and resistance to tin whisker growth ensure long-term electrical connectivity and minimize failure rates in high-reliability applications. While Sn-Pb alloy has historically been favored for its ease of use, the RoHS directive and demand for lead-free alternatives have accelerated the adoption of Sn-Ag-Cu in modern electronics manufacturing.

Environmental and Health Considerations

Sn-Pb alloys, commonly used in traditional soldering, raise environmental and health concerns due to lead's toxicity and bioaccumulation risks, causing soil and water contamination and posing neurological hazards to humans. Sn-Ag-Cu alloys, lead-free alternatives, exhibit significantly lower toxicity and reduced environmental impact, aligning with RoHS directives and minimizing hazardous waste generation. The transition to Sn-Ag-Cu alloys supports safer manufacturing practices and reduces long-term health liabilities associated with lead exposure.

Cost Analysis: Sn-Pb vs Sn-Ag-Cu Alloys

Sn-Pb alloys generally offer lower material costs compared to Sn-Ag-Cu alloys due to the cheaper availability of lead and tin raw materials. Sn-Ag-Cu alloys incur higher expenses because of the premium pricing of silver, impacting overall production budgets in electronics manufacturing. Total cost analysis must consider both initial material costs and long-term environmental compliance expenses associated with Sn-Pb alloys.

Applications and Industry Adoption Trends

Sn-Pb alloy remains widely used in traditional electronics manufacturing due to its excellent solderability and cost-efficiency, especially for through-hole components and legacy systems. Sn-Ag-Cu (SAC) alloy, favored in lead-free regulations such as RoHS, dominates modern electronics industries including consumer devices and automotive applications because of its superior mechanical strength and thermal fatigue resistance. Industry adoption is rapidly shifting towards Sn-Ag-Cu alloys driven by environmental compliance and reliability demands in high-performance sectors.

Sn-Pb Alloy vs Sn-Ag-Cu Alloy Infographic

materialdif.com

materialdif.com