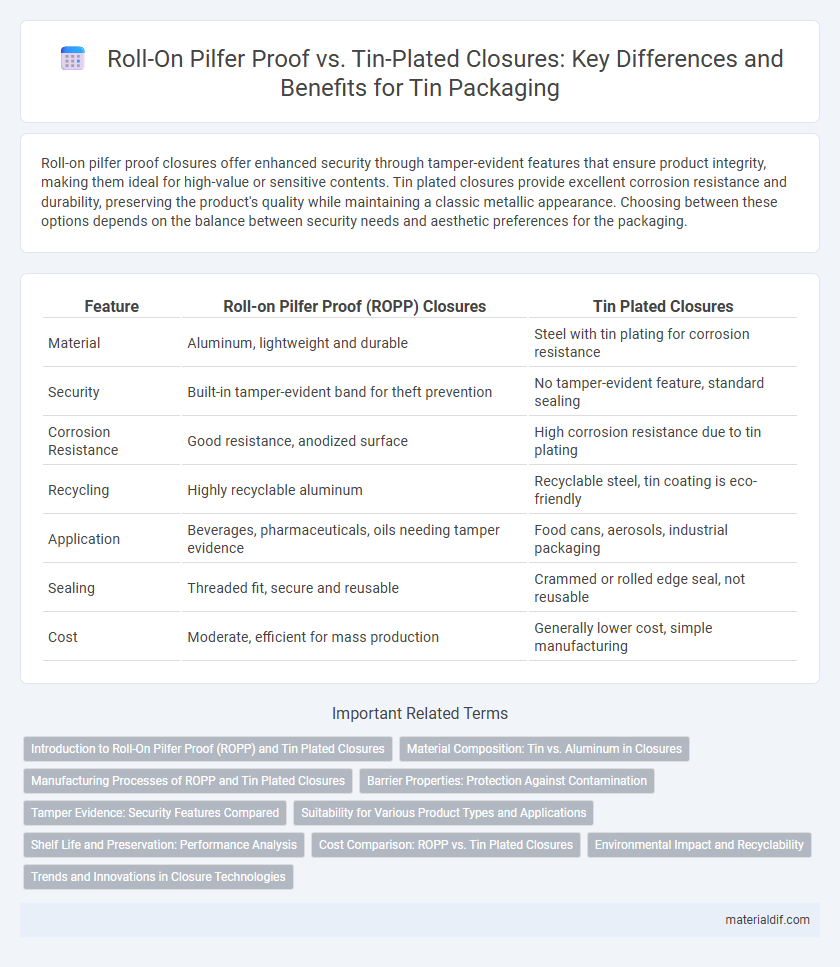

Roll-on pilfer proof closures offer enhanced security through tamper-evident features that ensure product integrity, making them ideal for high-value or sensitive contents. Tin plated closures provide excellent corrosion resistance and durability, preserving the product's quality while maintaining a classic metallic appearance. Choosing between these options depends on the balance between security needs and aesthetic preferences for the packaging.

Table of Comparison

| Feature | Roll-on Pilfer Proof (ROPP) Closures | Tin Plated Closures |

|---|---|---|

| Material | Aluminum, lightweight and durable | Steel with tin plating for corrosion resistance |

| Security | Built-in tamper-evident band for theft prevention | No tamper-evident feature, standard sealing |

| Corrosion Resistance | Good resistance, anodized surface | High corrosion resistance due to tin plating |

| Recycling | Highly recyclable aluminum | Recyclable steel, tin coating is eco-friendly |

| Application | Beverages, pharmaceuticals, oils needing tamper evidence | Food cans, aerosols, industrial packaging |

| Sealing | Threaded fit, secure and reusable | Crammed or rolled edge seal, not reusable |

| Cost | Moderate, efficient for mass production | Generally lower cost, simple manufacturing |

Introduction to Roll-On Pilfer Proof (ROPP) and Tin Plated Closures

Roll-On Pilfer Proof (ROPP) closures are metal caps formed by cold-forming aluminum or tinplate over a container's neck, ensuring tamper evidence and airtight sealing. Tin plated closures involve applying a thin layer of tin to steel or aluminum, enhancing corrosion resistance and providing a durable, food-safe surface for packaging. The choice between ROPP and tin plated closures depends on packaging requirements such as sealing integrity, tamper evidence, and environmental resistance.

Material Composition: Tin vs. Aluminum in Closures

Roll-on pilfer proof closures typically feature aluminum shells with LINER MATERIAL designed for tamper evidence, while tin-plated closures consist of steel with a thin layer of tin for corrosion resistance. The aluminum used in roll-on closures offers lightweight properties and excellent formability, whereas tin plating on steel provides enhanced protection against rust and extends shelf life. Choosing between tin and aluminum materials affects durability, resistance to environmental factors, and compatibility with different container types in packaging applications.

Manufacturing Processes of ROPP and Tin Plated Closures

Roll-on pilfer proof (ROPP) closures are manufactured using a high-precision cold forming process that shapes aluminum caps on a threading machine, ensuring tight sealing and tamper evidence, while tin plated closures involve a metal stamping process where steel or aluminum blanks are coated with a thin layer of tin through electrolytic or hot-dip plating to provide corrosion resistance. The ROPP process focuses on creating functional screw threads and integrated safety features directly on the cap, with aluminum's lightweight and malleability being crucial, whereas tin plated closures emphasize coating uniformity and adhesion to enhance barrier properties and metal durability. Quality control in ROPP includes thread dimension verification and torque testing, while for tin plated closures, solderability, coating thickness, and peel strength are critical parameters impacting performance in food and beverage packaging.

Barrier Properties: Protection Against Contamination

Roll-on pilfer proof closures offer enhanced barrier properties by creating a secure, tamper-evident seal that prevents contamination and preserves product integrity. Tin plated closures provide robust corrosion resistance and a reliable barrier against moisture and oxygen, ensuring shelf-life stability. Both closure types utilize tin's protective qualities, but roll-on pilfer proof closures add an extra layer of contamination protection through their specialized sealing mechanism.

Tamper Evidence: Security Features Compared

Roll-on pilfer proof (ROPP) closures provide enhanced tamper evidence through a tear-off band that clearly shows if the container has been opened, improving product security. Tin plated closures offer a durable barrier against contamination but generally lack the integrated tamper-evident features found in ROPP designs. The visible breakaway band of ROPP closures makes them a preferred choice for industries requiring stringent anti-counterfeiting measures.

Suitability for Various Product Types and Applications

Roll-on pilfer proof (ROPP) closures provide excellent sealing and tamper-evident features, making them highly suitable for beverages, pharmaceuticals, and chemicals requiring secure, leak-proof packaging. Tin plated closures offer superior corrosion resistance and are ideal for food products and cosmetics where long shelf life and product safety are critical. Both options cater to different product requirements, with ROPP closures emphasizing security and ease of use, while tin plated closures prioritize durability and protection against contamination.

Shelf Life and Preservation: Performance Analysis

Roll-on pilfer proof closures provide superior shelf life by creating an airtight seal that prevents contamination and oxidization, thereby preserving the contents more effectively than standard tin-plated closures. Tin-plated closures, while offering basic protection due to their corrosion-resistant coating, are more prone to leakage and do not guarantee consistent preservation under fluctuating storage conditions. Performance analysis confirms that roll-on pilfer proof closures enhance product integrity and extend shelf life in comparison to traditional tin-plated options.

Cost Comparison: ROPP vs. Tin Plated Closures

Roll-on pilfer proof (ROPP) closures generally incur higher upfront costs due to their precision threading and tamper-evident features compared to tin plated closures, which are simpler and less expensive to produce. Tin plated closures offer cost advantages in large-scale production since they require less complex machinery and materials, reducing overall manufacturing expenses. However, the higher initial investment in ROPP closures can be offset by enhanced security and consumer trust, potentially reducing losses and increases in brand value.

Environmental Impact and Recyclability

Roll-on pilfer proof (ROPP) closures, typically made from aluminum, offer superior recyclability due to aluminum's high recovery rate and energy-efficient recycling process compared to tin plated closures, which involve a tin coating over steel that complicates recycling streams. The environmental impact of ROPP closures is generally lower given aluminum's lighter weight, reducing transportation emissions, while tin plated closures contribute more to landfill waste when not properly recycled. Both types require appropriate recycling facilities, but ROPP closures align better with circular economy goals through enhanced sustainability and reduced carbon footprint.

Trends and Innovations in Closure Technologies

Roll-on pilfer-proof (ROPP) closures exhibit growing adoption in the beverage and food industries due to their tamper-evident features and ease of application, fueling demand for precision-engineered tinplate materials. Innovations in tin-plated closures emphasize improved corrosion resistance and lightweight designs that enhance sustainability without compromising barrier integrity. Emerging trends include hybrid coatings on tinplate, enabling superior printability and compatibility with automated closure systems, aligning with evolving regulatory standards and consumer preferences.

Roll-on pilfer proof vs Tin plated closures Infographic

materialdif.com

materialdif.com