Wetted tin forms a strong metallurgical bond with underlying surfaces, ensuring reliable electrical conductivity and mechanical stability in electronic components. Unwetted tin lacks proper adhesion, leading to potential issues such as whisker growth, poor solder joint integrity, and increased risk of corrosion. Choosing wetted tin over unwetted tin enhances the durability and performance of soldered connections in electronic assemblies.

Table of Comparison

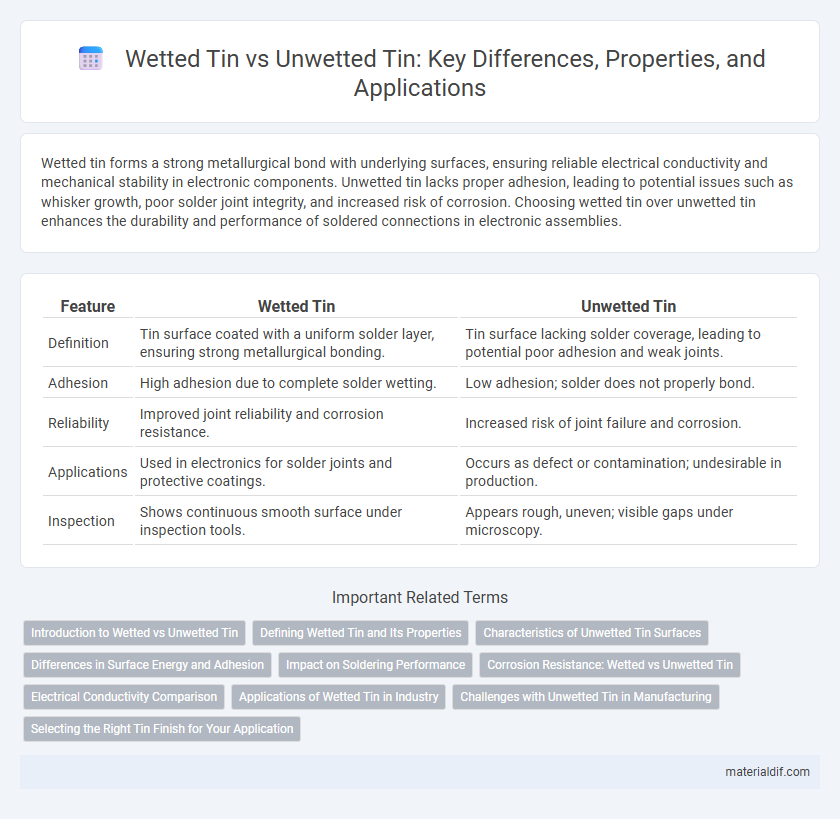

| Feature | Wetted Tin | Unwetted Tin |

|---|---|---|

| Definition | Tin surface coated with a uniform solder layer, ensuring strong metallurgical bonding. | Tin surface lacking solder coverage, leading to potential poor adhesion and weak joints. |

| Adhesion | High adhesion due to complete solder wetting. | Low adhesion; solder does not properly bond. |

| Reliability | Improved joint reliability and corrosion resistance. | Increased risk of joint failure and corrosion. |

| Applications | Used in electronics for solder joints and protective coatings. | Occurs as defect or contamination; undesirable in production. |

| Inspection | Shows continuous smooth surface under inspection tools. | Appears rough, uneven; visible gaps under microscopy. |

Introduction to Wetted vs Unwetted Tin

Wetted tin refers to tin that has formed a metallurgical bond with a substrate, promoting strong adhesion and reliable electrical conductivity in electronic components. Unwetted tin, by contrast, occurs when tin fails to bond properly with the underlying surface, often resulting in poor solder joint integrity and increased risk of component failure. Understanding the differences between wetted and unwetted tin is critical for optimizing soldering processes and ensuring long-term circuit board reliability.

Defining Wetted Tin and Its Properties

Wetted tin refers to tin metal that has undergone the soldering process, forming a strong metallurgical bond with another metal surface, typically copper or nickel. This bond enhances electrical conductivity and corrosion resistance, making wetted tin ideal for electronic connectors and components. Unwetted tin, by contrast, lacks this metallurgical interface, resulting in weaker adhesion and inferior performance in high-reliability applications.

Characteristics of Unwetted Tin Surfaces

Unwetted tin surfaces exhibit poor solderability due to the presence of oxide layers and contaminants that inhibit proper bonding with molten solder. These surfaces often result in higher contact resistance and increased risk of joint failure in electronic assemblies. The lack of wetting also leads to uneven solder distribution, causing weak mechanical strength in the final solder joint.

Differences in Surface Energy and Adhesion

Wetted tin exhibits higher surface energy compared to unwetted tin, promoting stronger adhesion to substrates due to enhanced atomic bonding at the interface. The increased surface energy in wetted tin results from the formation of a clean, oxide-free surface that facilitates better wetting and metallurgical bonding. Unwetted tin shows lower adhesion and surface energy, often hindering effective tin layer formation on components in electronic packaging and soldering applications.

Impact on Soldering Performance

Wetted tin significantly enhances soldering performance by providing superior wetting ability, reducing voids, and ensuring strong metallurgical bonds with solder alloys. Unwetted tin surfaces often lead to poor solder joint formation, increased risk of cold joints, and lower mechanical reliability due to inadequate solder adhesion. Optimizing wettability with proper surface treatments or alloy modifications is critical for achieving consistent, high-quality solder connections in electronic assemblies.

Corrosion Resistance: Wetted vs Unwetted Tin

Wetted tin exhibits superior corrosion resistance compared to unwetted tin due to the formation of a uniform, adherent oxide layer that protects the underlying metal from environmental factors. Unwetted tin surfaces lack this consistent oxide coverage, making them more susceptible to pitting and galvanic corrosion. The presence of wetted tin in electronic components enhances reliability by minimizing corrosion-related failure mechanisms.

Electrical Conductivity Comparison

Wetted tin exhibits higher electrical conductivity than unwetted tin due to improved surface contact and reduced oxide formation, which enhances electron flow in electronic components. Unwetted tin surfaces often suffer from increased resistivity caused by oxide layers that impede current conduction. The conductivity difference significantly impacts the performance and reliability of solder joints in electrical circuits, with wetted tin providing superior electrical connectivity.

Applications of Wetted Tin in Industry

Wetted tin, characterized by its excellent solderability and conductivity, is widely applied in the electronics industry for coating printed circuit boards (PCBs) and electronic connectors, ensuring reliable electrical connections and corrosion resistance. Industries such as automotive and aerospace utilize wetted tin for components requiring robust mechanical bonding and enhanced thermal management. Its ability to form consistent, high-quality solder joints makes wetted tin indispensable in manufacturing semiconductors, consumer electronics, and communication devices.

Challenges with Unwetted Tin in Manufacturing

Unwetted tin presents significant challenges in manufacturing due to poor adhesion on substrates, leading to unreliable solder joints and increased failure rates. Its inconsistent wetting behavior causes defects such as voids and insufficient mechanical strength in electronic assemblies. Overcoming these issues requires precise surface preparation and advanced flux formulations to enhance tin's wettability and ensure robust connections.

Selecting the Right Tin Finish for Your Application

Selecting the appropriate tin finish requires understanding the differences between wetted and unwetted tin surfaces. Wetted tin provides superior solderability and corrosion resistance, making it ideal for electronic components exposed to harsh environments. Unwetted tin, lacking consistent solder adhesion, is better suited for applications where electrical conductivity is less critical and cost efficiency is prioritized.

Wetted tin vs Unwetted tin Infographic

materialdif.com

materialdif.com