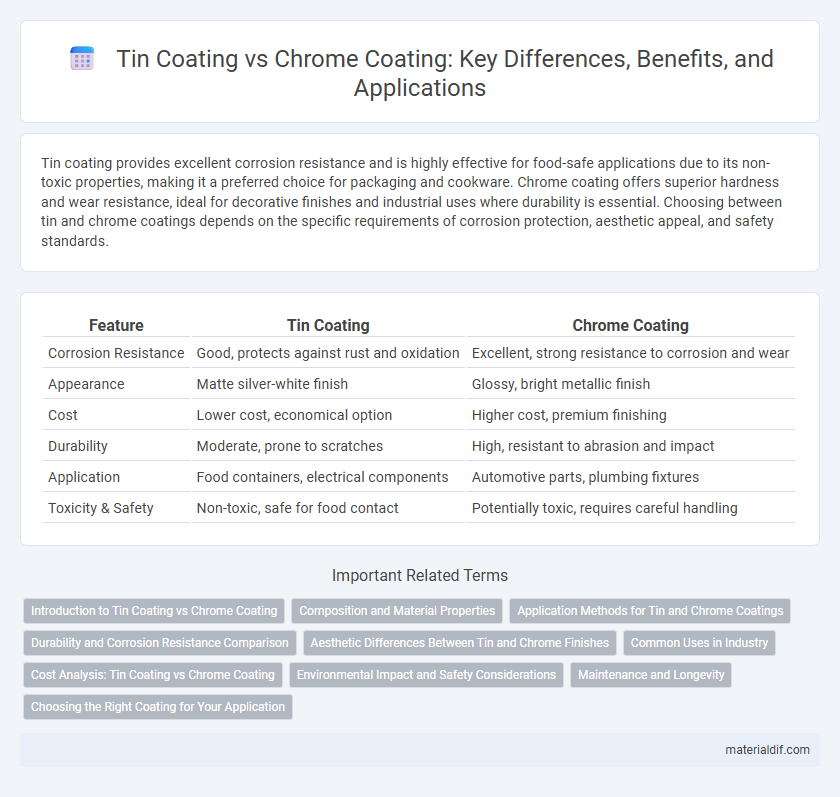

Tin coating provides excellent corrosion resistance and is highly effective for food-safe applications due to its non-toxic properties, making it a preferred choice for packaging and cookware. Chrome coating offers superior hardness and wear resistance, ideal for decorative finishes and industrial uses where durability is essential. Choosing between tin and chrome coatings depends on the specific requirements of corrosion protection, aesthetic appeal, and safety standards.

Table of Comparison

| Feature | Tin Coating | Chrome Coating |

|---|---|---|

| Corrosion Resistance | Good, protects against rust and oxidation | Excellent, strong resistance to corrosion and wear |

| Appearance | Matte silver-white finish | Glossy, bright metallic finish |

| Cost | Lower cost, economical option | Higher cost, premium finishing |

| Durability | Moderate, prone to scratches | High, resistant to abrasion and impact |

| Application | Food containers, electrical components | Automotive parts, plumbing fixtures |

| Toxicity & Safety | Non-toxic, safe for food contact | Potentially toxic, requires careful handling |

Introduction to Tin Coating vs Chrome Coating

Tin coating offers excellent corrosion resistance and solderability, making it a preferred choice for electrical components and food packaging applications. Chrome coating provides superior hardness, wear resistance, and aesthetic appeal, commonly used in automotive parts and decorative finishes. The selection between tin and chrome coatings depends on specific requirements such as durability, corrosion protection, and visual appearance.

Composition and Material Properties

Tin coating primarily consists of pure tin or tin alloys, providing excellent corrosion resistance and solderability due to its low toxicity and good wettability. Chrome coating, composed mainly of chromium or chromium compounds, is valued for its high hardness, wear resistance, and shiny, decorative finish. Tin offers superior electrical conductivity and is softer, while chrome provides greater durability and resistance to abrasion and oxidation.

Application Methods for Tin and Chrome Coatings

Tin coatings are primarily applied through electroplating and hot-dip processes, offering excellent corrosion resistance and solderability for electronic components and food packaging. Chrome coatings utilize electroplating with hexavalent or trivalent chromium baths, typically chosen for decorative finishes and wear resistance on automotive and hardware parts. Both methods require precise control of bath composition and current density to achieve uniform, adherent coatings tailored to specific industrial applications.

Durability and Corrosion Resistance Comparison

Tin coating offers excellent corrosion resistance due to its ability to form a stable oxide layer, making it highly effective in protecting steel substrates from rust and oxidation. Chrome coating provides superior durability and hardness, enhancing wear resistance and maintaining aesthetic appeal under mechanical stress and high temperatures. While chrome excels in mechanical durability, tin is preferred in environments requiring superior corrosion resistance, especially in food and chemical applications.

Aesthetic Differences Between Tin and Chrome Finishes

Tin coatings exhibit a matte, silvery-gray appearance that offers a subtle, vintage aesthetic often preferred for traditional or rustic designs. Chrome coatings deliver a highly reflective, mirror-like shine that creates a modern, sleek, and polished look, enhancing visual brightness and depth. The aesthetic choice between tin and chrome finishes depends on the desired ambiance, with tin providing understated elegance and chrome emphasizing bold, contemporary appeal.

Common Uses in Industry

Tin coating is widely used in the food packaging industry due to its excellent corrosion resistance and non-toxic properties, making it ideal for preserving canned goods. Chrome coating, favored in automotive and tooling industries, provides superior hardness and wear resistance, enhancing durability under high-friction conditions. Both coatings serve protective functions but are selected based on specific industrial requirements like chemical stability or mechanical strength.

Cost Analysis: Tin Coating vs Chrome Coating

Tin coating offers a more cost-effective solution compared to chrome coating, primarily due to lower raw material and processing expenses. Chrome coating involves higher energy consumption and complex plating procedures, significantly increasing overall costs. While chrome provides superior hardness and corrosion resistance, tin's affordability makes it preferable for budget-sensitive applications requiring moderate durability.

Environmental Impact and Safety Considerations

Tin coating offers superior environmental benefits due to its non-toxic, non-carcinogenic properties and excellent recyclability, minimizing hazardous waste. Chrome coating, especially hexavalent chromium, poses significant environmental hazards, including soil and water contamination and health risks like respiratory issues and carcinogenic exposure. Regulatory restrictions on hexavalent chromium use highlight the safety advantage of tin coatings in industrial applications.

Maintenance and Longevity

Tin coating offers superior corrosion resistance with minimal maintenance, making it ideal for applications exposed to moisture and mild chemicals. Chrome coating provides excellent hardness and wear resistance but requires regular cleaning to prevent dulling and corrosion in harsh environments. Both coatings extend the lifespan of metal parts, with tin excelling in longevity under corrosive conditions and chrome favored for durability against physical abrasion.

Choosing the Right Coating for Your Application

Tin coating offers excellent corrosion resistance and solderability, making it ideal for electronic components and food packaging applications where non-toxicity and conductivity are crucial. Chrome coating provides superior hardness and wear resistance, suited for automotive parts and industrial tools requiring high durability and aesthetic appeal. Selecting the right coating depends on specific requirements such as environmental exposure, mechanical stress, and regulatory standards related to the final product application.

Tin Coating vs Chrome Coating Infographic

materialdif.com

materialdif.com