A solid tin coating provides a durable, corrosion-resistant layer that ensures long-lasting protection for metal surfaces, making it ideal for applications requiring enhanced wear resistance. Thin tin flash, by contrast, offers only a minimal protective layer mainly for aesthetic purposes or brief exposure to moisture, which can wear off quickly under harsh conditions. Choosing solid tin over thin tin flash improves solderability and electrical conductivity, critical for electronic components and connectors.

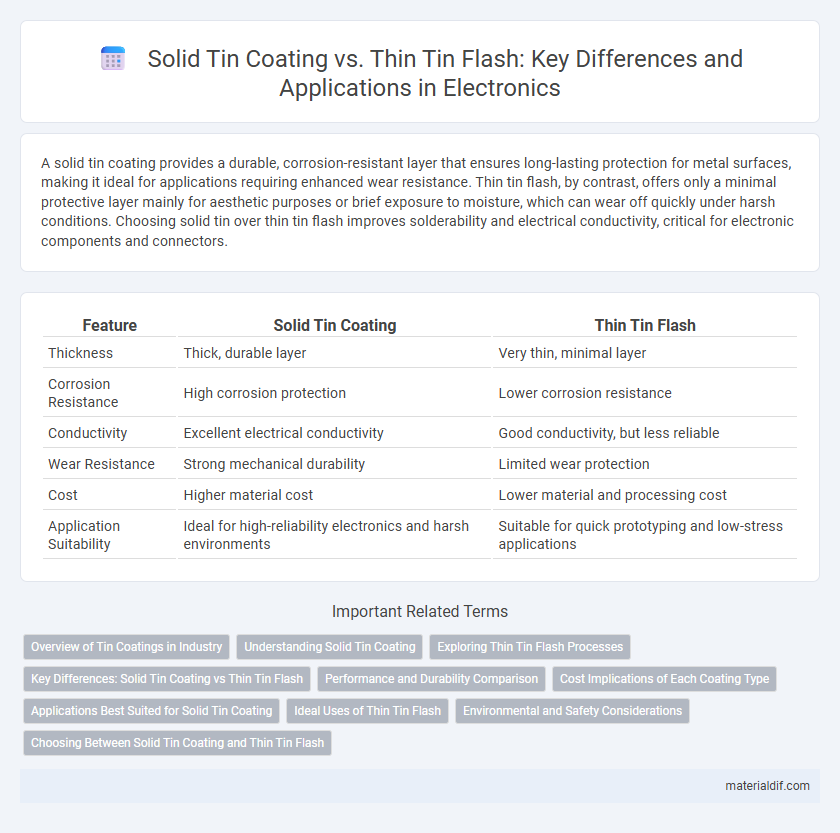

Table of Comparison

| Feature | Solid Tin Coating | Thin Tin Flash |

|---|---|---|

| Thickness | Thick, durable layer | Very thin, minimal layer |

| Corrosion Resistance | High corrosion protection | Lower corrosion resistance |

| Conductivity | Excellent electrical conductivity | Good conductivity, but less reliable |

| Wear Resistance | Strong mechanical durability | Limited wear protection |

| Cost | Higher material cost | Lower material and processing cost |

| Application Suitability | Ideal for high-reliability electronics and harsh environments | Suitable for quick prototyping and low-stress applications |

Overview of Tin Coatings in Industry

Solid tin coating provides a durable, thick layer of pure tin that offers excellent corrosion resistance and solderability, essential for electronic components and connectors. Thin tin flash, a very light deposit of tin, is primarily used as an underlayer to improve adhesion and prevent copper oxidation in plating processes. These tin coatings are critical in industries such as electronics, automotive, and packaging, where surface protection and electrical conductivity are paramount.

Understanding Solid Tin Coating

Solid tin coating provides a uniform, robust layer of pure tin that enhances corrosion resistance and solderability on metal surfaces. Unlike thin tin flash, which is a minimal, often uneven layer used for basic protection, solid tin coatings offer greater durability and improved electrical conductivity, making them ideal for electronics and industrial applications. The thickness and purity of solid tin coatings are critical factors that ensure long-term performance and reliability in harsh environments.

Exploring Thin Tin Flash Processes

Thin tin flash processes involve applying an ultra-thin layer of tin, typically less than one micron, to substrates for enhanced corrosion resistance and improved solderability in electronics. Compared to solid tin coatings, thin tin flash uses less material while providing sufficient protection against oxidation and excellent wetting properties, crucial for high-density circuit boards. This technique supports fine-pitch components by minimizing thickness buildup, ensuring electrical performance and mechanical reliability in advanced semiconductor packaging.

Key Differences: Solid Tin Coating vs Thin Tin Flash

Solid tin coating provides a robust, uniform layer of tin with a typical thickness ranging from 5 to 25 microns, offering superior corrosion resistance and enhanced solderability compared to thin tin flash. Thin tin flash, often less than 1 micron thick, serves primarily as a minimal barrier against oxidation but lacks the mechanical durability and long-term protection characteristic of solid coatings. The choice between solid tin coating and thin tin flash depends on application requirements, with solid coatings favored in demanding environments for reliable performance and thin flashes used in cost-sensitive or less critical applications.

Performance and Durability Comparison

Solid tin coating provides superior corrosion resistance and enhanced durability compared to thin tin flash, ensuring longer-lasting protection in harsh environments. Thin tin flash offers minimal material thickness that may lead to quicker wear and reduced performance under mechanical stress or exposure to moisture. For applications demanding high reliability and extended service life, solid tin coating is the preferred choice due to its robust and consistent coverage.

Cost Implications of Each Coating Type

Solid tin coating incurs higher initial material costs due to the thicker layer of tin applied, which enhances corrosion resistance and solderability in electronic components. Thin tin flash offers a cost-effective alternative by using minimal tin, reducing material expenses but potentially sacrificing long-term durability and protection. Choosing between solid tin and thin tin flash depends on balancing upfront coating costs with the anticipated performance requirements and lifecycle costs of the final product.

Applications Best Suited for Solid Tin Coating

Solid tin coating offers superior corrosion resistance and durability compared to thin tin flash, making it ideal for electrical connectors, electronic components, and automotive parts requiring long-term reliability and protection against harsh environments. Its thicker layer provides enhanced solderability and wear resistance, essential in high-performance applications where frequent handling or mechanical stress occurs. Industries such as aerospace and telecommunications benefit from solid tin coatings due to their ability to maintain consistent conductivity and prevent oxidation over extended periods.

Ideal Uses of Thin Tin Flash

Thin tin flash provides a lightweight, cost-effective coating ideal for electronic components requiring minimal corrosion protection and excellent solderability. It is commonly used in printed circuit boards (PCBs) and connectors where precise conductivity and quick assembly are essential without the bulk of solid tin plating. This approach optimizes manufacturing efficiency while maintaining necessary electrical performance.

Environmental and Safety Considerations

Solid tin coatings provide a thicker, more durable barrier that significantly reduces the risk of corrosion-related contamination, enhancing environmental safety by minimizing heavy metal leaching. Thin tin flash layers, although cost-effective, are more susceptible to wear and damage, potentially exposing base metals and increasing environmental hazards through metal ion release. Choosing solid tin coating supports safer handling and disposal practices, aligning better with stringent environmental regulations and workplace safety standards.

Choosing Between Solid Tin Coating and Thin Tin Flash

Choosing between solid tin coating and thin tin flash depends on the specific application requirements, including corrosion resistance and solderability. Solid tin coatings provide a thicker, more durable layer ideal for protecting components from environmental damage and mechanical wear. Thin tin flash, although less robust, offers sufficient conductivity and solderability for applications where minimal coating thickness is critical to maintain tight tolerances.

Solid tin coating vs Thin tin flash Infographic

materialdif.com

materialdif.com