Hot-dipped tinning creates a thicker, more durable coating by immersing metal in molten tin, providing excellent corrosion resistance and long-lasting protection. Electroplating deposits a thinner, more uniform tin layer using an electric current, resulting in better surface finish and precise control over coating thickness. Both methods enhance solderability and protect against oxidation, but hot-dipped tinning is preferred for heavy-duty applications while electroplating suits delicate or detailed components.

Table of Comparison

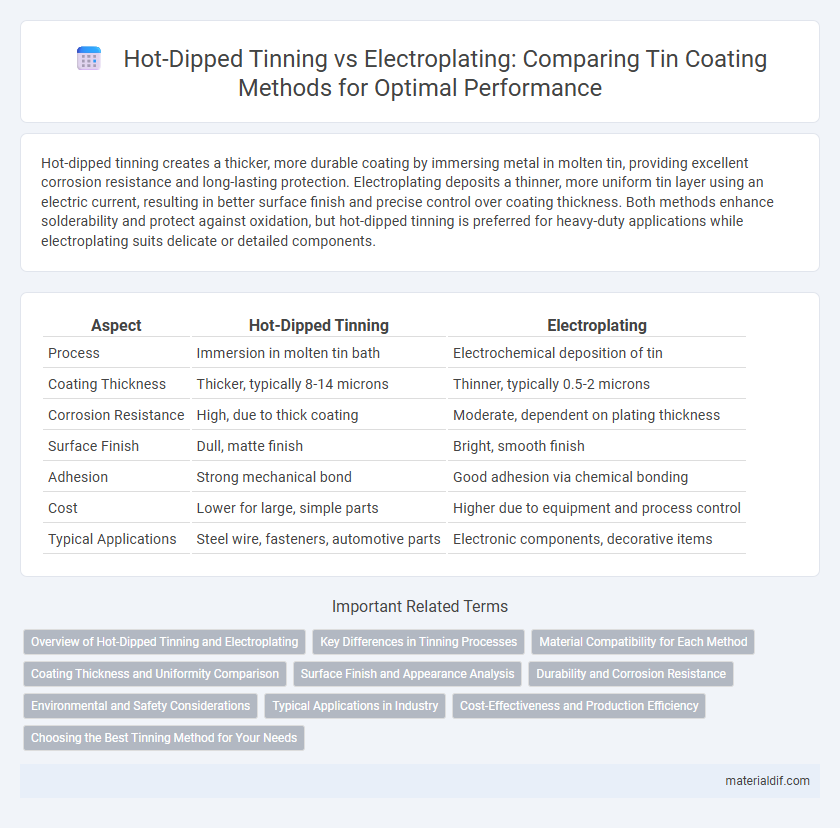

| Aspect | Hot-Dipped Tinning | Electroplating |

|---|---|---|

| Process | Immersion in molten tin bath | Electrochemical deposition of tin |

| Coating Thickness | Thicker, typically 8-14 microns | Thinner, typically 0.5-2 microns |

| Corrosion Resistance | High, due to thick coating | Moderate, dependent on plating thickness |

| Surface Finish | Dull, matte finish | Bright, smooth finish |

| Adhesion | Strong mechanical bond | Good adhesion via chemical bonding |

| Cost | Lower for large, simple parts | Higher due to equipment and process control |

| Typical Applications | Steel wire, fasteners, automotive parts | Electronic components, decorative items |

Overview of Hot-Dipped Tinning and Electroplating

Hot-dipped tinning involves immersing metal components in molten tin, creating a thick, durable coating that offers superior corrosion resistance and enhanced solderability, ideal for heavy-duty applications. Electroplating deposits a thin, uniform layer of tin on the substrate through an electrolytic process, ensuring precise coating control suitable for delicate electronic parts. Both methods enhance metal longevity and conductivity, but hot-dipped tinning provides a more robust barrier, while electroplating excels in surface finish and thickness uniformity.

Key Differences in Tinning Processes

Hot-dipped tinning involves immersing the metal substrate in molten tin, creating a thick, robust coating with excellent corrosion resistance and strong adhesion, ideal for heavy-duty applications. Electroplating deposits a thin, uniform tin layer using an electrolytic process, offering precise control over coating thickness and superior surface finish for delicate or intricate components. Key differences include coating thickness, adhesion strength, processing time, and suitability for complex shapes, with hot-dipped tinning favored for durability and electroplating preferred for aesthetic and precision requirements.

Material Compatibility for Each Method

Hot-dipped tinning is highly compatible with steel substrates, providing a robust, corrosion-resistant coating through metallurgical bonding. Electroplating offers greater versatility, enabling tin deposition on various metals including copper, brass, and aluminum with precise thickness control. Material selection influences adhesion quality and requires tailored surface preparation to maximize coating durability for each method.

Coating Thickness and Uniformity Comparison

Hot-dipped tinning generally produces a thicker and more uniform coating, typically ranging from 2 to 10 microns, due to the immersion of the substrate in molten tin, which ensures comprehensive metal coverage. Electroplating coats are usually thinner, around 0.5 to 5 microns, and can exhibit varying uniformity depending on current distribution and bath composition. The consistent thickness of hot-dipped tin provides superior corrosion resistance, while electroplating offers more precise control for applications requiring finer coatings.

Surface Finish and Appearance Analysis

Hot-dipped tinning creates a thick, matte to semi-gloss surface finish characterized by a slightly uneven texture due to the molten tin coating. Electroplating yields a smooth, bright, and highly uniform surface with superior aesthetic appeal and finer control over thickness. Surface finish analysis reveals that hot-dipped tinning offers higher corrosion resistance but less visual uniformity compared to the aesthetically polished, thin, and consistent electroplated tin layers.

Durability and Corrosion Resistance

Hot-dipped tinning provides a thicker, more durable coating compared to electroplating, enhancing corrosion resistance especially in harsh environments. The molten tin layer formed during hot-dipping offers superior adhesion and uniform coverage, significantly reducing the risk of peeling or flaking over time. Electroplated tin layers, while precise and smooth, tend to be thinner and more susceptible to wear and corrosion, limiting their longevity in demanding applications.

Environmental and Safety Considerations

Hot-dipped tinning involves immersing metals in molten tin, producing a thicker, more durable coating with fewer toxic byproducts compared to electroplating, which often uses hazardous chemicals like cyanide or chromium compounds. The electroplating process requires stringent waste treatment protocols to prevent environmental contamination and poses higher risks to worker safety due to exposure to toxic electrolytes and heavy metals. Hot-dipped tinning offers a safer alternative, reducing hazardous waste generation and minimizing occupational health hazards associated with chemical handling.

Typical Applications in Industry

Hot-dipped tinning is commonly used in industries requiring robust corrosion resistance and heavy-duty protection, such as automotive parts manufacturing and electrical cable coatings. Electroplating is preferred for precise control over coating thickness, making it ideal for electronics, circuit boards, and decorative hardware. Both methods enhance conductivity and solderability but serve different functional requirements based on application demands.

Cost-Effectiveness and Production Efficiency

Hot-dipped tinning offers superior cost-effectiveness due to lower material and energy expenses compared to electroplating, which requires complex and expensive chemical baths. Production efficiency is higher with hot-dipped tinning because it enables faster coating of large surface areas and reduces cycle times without frequent bath maintenance. While electroplating provides precise thickness control, its longer setup and processing times often increase overall production costs.

Choosing the Best Tinning Method for Your Needs

Hot-dipped tinning provides a thick, durable coating ideal for corrosion resistance in industrial applications, while electroplating offers precise, thin layers suitable for delicate electronics and decorative purposes. Evaluating factors such as environmental exposure, mechanical wear, and budget constraints helps determine the optimal tinning method for specific project requirements. Selecting the best tinning process enhances product longevity and performance by aligning surface protection with operational conditions.

hot-dipped tinning vs electroplating Infographic

materialdif.com

materialdif.com