Refined tin offers superior purity and enhanced mechanical properties compared to unrefined tin, making it ideal for high-precision applications in electronics and soldering. Unrefined tin contains impurities that can affect its conductivity and corrosion resistance, limiting its use to less demanding industrial processes. Choosing refined tin ensures better performance, reliability, and longevity in critical manufacturing environments.

Table of Comparison

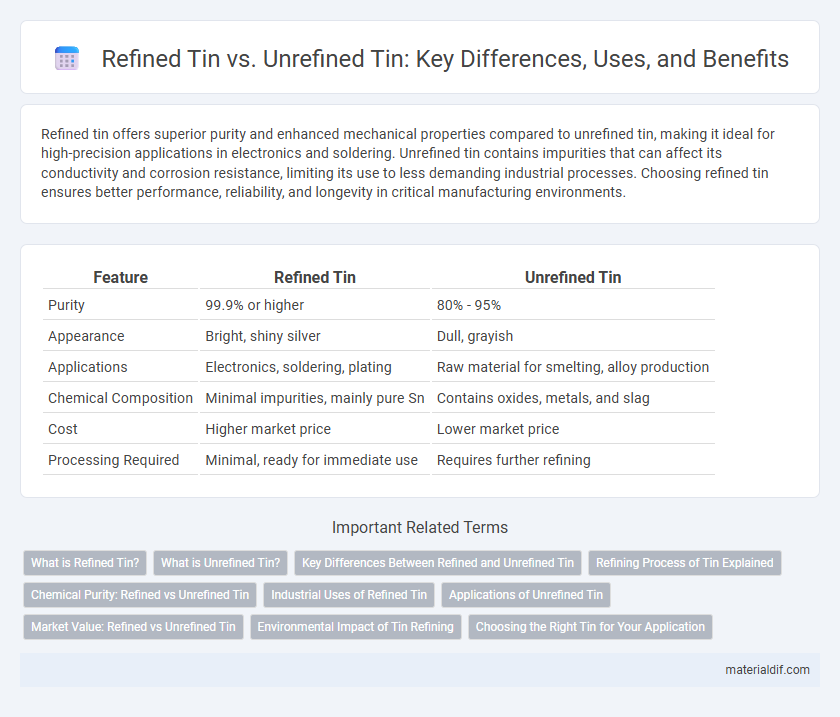

| Feature | Refined Tin | Unrefined Tin |

|---|---|---|

| Purity | 99.9% or higher | 80% - 95% |

| Appearance | Bright, shiny silver | Dull, grayish |

| Applications | Electronics, soldering, plating | Raw material for smelting, alloy production |

| Chemical Composition | Minimal impurities, mainly pure Sn | Contains oxides, metals, and slag |

| Cost | Higher market price | Lower market price |

| Processing Required | Minimal, ready for immediate use | Requires further refining |

What is Refined Tin?

Refined tin is tin metal that has undergone purification processes such as electrolysis or chemical treatments to remove impurities, resulting in higher purity levels typically exceeding 99.9%. This high-grade tin exhibits improved conductivity, malleability, and corrosion resistance, making it ideal for applications in electronics, soldering, and plating. In contrast, unrefined tin contains various contaminants that compromise its physical and chemical properties, limiting its industrial usability.

What is Unrefined Tin?

Unrefined tin is a raw form of tin extracted directly from tin ores, containing various impurities such as iron, copper, and other metals. This crude metal requires further refining processes like electrolytic refining or the addition of flux to achieve the high purity levels needed for industrial applications. The primary distinction between unrefined and refined tin lies in purity, with unrefined tin often having less than 99% tin content compared to the nearly 99.9% purity of refined tin.

Key Differences Between Refined and Unrefined Tin

Refined tin contains a purity level exceeding 99.9%, making it ideal for applications requiring high corrosion resistance and excellent electrical conductivity, such as in electronics and soldering. Unrefined tin retains impurities like iron, copper, and bismuth, which reduce its ductility and mechanical strength, limiting its use to less demanding industrial applications. The refining process involves techniques like electrolysis or acidic leaching, which remove contaminants to enhance tin's quality and performance characteristics.

Refining Process of Tin Explained

Refined tin undergoes a purification process involving smelting and electrolytic refining to remove impurities such as iron, lead, and zinc, resulting in high-purity tin suitable for industrial applications. Unrefined tin contains higher levels of contaminants and alloys that compromise its quality and limit its use in electronics, soldering, and plating. The refining process enhances the metal's conductivity, malleability, and corrosion resistance, making refined tin essential for manufacturing reliable electronic components and coatings.

Chemical Purity: Refined vs Unrefined Tin

Refined tin typically achieves chemical purity levels above 99.9%, making it ideal for applications requiring high conductivity and corrosion resistance, such as electronics and plating. Unrefined tin contains various impurities like lead, iron, and copper, resulting in lower purity that affects its mechanical properties and limits its usage to less critical industries. The refinement process involves smelting and electrolytic refining to remove these contaminants, enhancing tin's chemical stability and performance.

Industrial Uses of Refined Tin

Refined tin, characterized by its purity of 99.9% or higher, is essential in industrial applications such as soldering, plating, and alloy production due to its superior conductivity and corrosion resistance. Unrefined tin contains impurities that reduce its effectiveness for these precise industrial processes, limiting its use primarily to preliminary stages of smelting or as a raw material for further refinement. Industrial sectors including electronics manufacturing, automotive parts, and packaging heavily depend on refined tin for reliable and high-performance components.

Applications of Unrefined Tin

Unrefined tin, containing impurities, is primarily used in applications where high purity is not critical, such as in solder manufacturing, certain alloys, and as a protective coating for metals to prevent corrosion. Its lower cost compared to refined tin makes it suitable for use in heavy-duty materials and industrial processes like tin plating in electronics and machinery parts. Despite its less pure composition, unrefined tin plays a significant role in construction and automotive industries where durability and cost-efficiency are prioritized.

Market Value: Refined vs Unrefined Tin

Refined tin commands a higher market value due to its purity, meeting stringent industry standards for electronics and soldering applications. Unrefined tin, containing impurities and alloy elements, is typically sold at a lower price reflecting the additional processing required for refinement. Market demand heavily favors refined tin for its reliability and performance, influencing pricing dynamics in global metals trading.

Environmental Impact of Tin Refining

Refined tin production significantly reduces environmental contaminants compared to unrefined tin, as modern refining techniques minimize the release of hazardous substances like mercury and acid gases. Unrefined tin extraction often leads to extensive soil and water pollution due to improper waste management and the presence of heavy metals. Sustainable refining processes and strict regulatory compliance are essential to mitigating the environmental footprint of tin production, promoting safer ecosystems and reducing long-term ecological damage.

Choosing the Right Tin for Your Application

Refined tin offers higher purity levels, typically above 99.9%, making it ideal for electronic soldering, plating, and food-grade applications where contamination must be minimized. Unrefined tin contains impurities that can affect its mechanical properties and corrosion resistance, suited mainly for industrial uses like alloy production or casting where such precision is less critical. Selecting the right tin depends on balancing cost with application requirements, ensuring performance and safety standards are met.

Refined tin vs Unrefined tin Infographic

materialdif.com

materialdif.com