Tin bronze offers superior corrosion resistance and strength compared to tin brass, making it ideal for heavy-duty applications and marine environments. Tin brass, while containing less tin, provides better machinability and is often preferred for decorative hardware due to its bright, golden appearance. Both alloys benefit from tin's ability to enhance durability, but tin bronze excels where mechanical performance is critical.

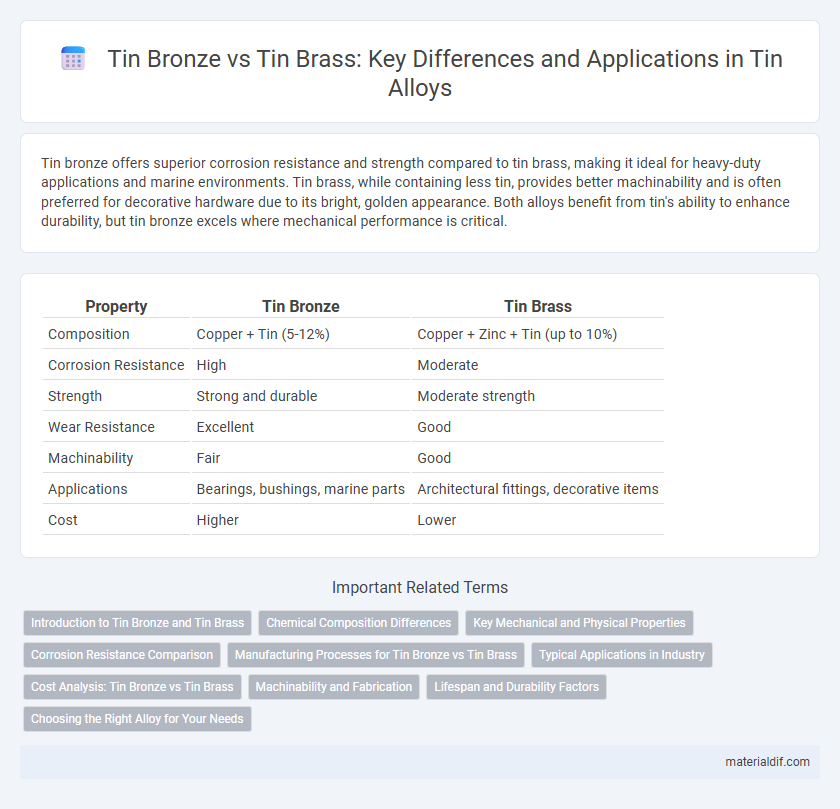

Table of Comparison

| Property | Tin Bronze | Tin Brass |

|---|---|---|

| Composition | Copper + Tin (5-12%) | Copper + Zinc + Tin (up to 10%) |

| Corrosion Resistance | High | Moderate |

| Strength | Strong and durable | Moderate strength |

| Wear Resistance | Excellent | Good |

| Machinability | Fair | Good |

| Applications | Bearings, bushings, marine parts | Architectural fittings, decorative items |

| Cost | Higher | Lower |

Introduction to Tin Bronze and Tin Brass

Tin bronze is an alloy primarily composed of copper and tin, known for its excellent corrosion resistance and mechanical strength, commonly used in bearings, bushings, and marine hardware. Tin brass combines copper, zinc, and tin, offering improved machinability and moderate strength, making it suitable for decorative items and musical instruments. The key distinction lies in tin bronze's superior durability due to higher tin content, while tin brass balances cost and workability with added zinc.

Chemical Composition Differences

Tin bronze primarily consists of copper and tin, typically containing 12-15% tin, which enhances its strength, corrosion resistance, and wear properties. Tin brass, on the other hand, is an alloy of copper, zinc, and a smaller percentage of tin, generally around 1-5%, where zinc improves machinability and tin increases corrosion resistance slightly. The key chemical difference lies in tin bronze's higher tin content and absence of zinc, whereas tin brass combines moderate tin with significant zinc, resulting in distinct mechanical and chemical characteristics.

Key Mechanical and Physical Properties

Tin bronze, an alloy primarily composed of copper and tin, offers superior corrosion resistance, excellent wear resistance, and higher tensile strength compared to tin brass. Tin brass, which consists of copper, zinc, and a small percentage of tin, provides better machinability and ductility but has lower corrosion resistance and mechanical strength. The key physical difference lies in tin bronze's enhanced hardness and fatigue resistance, making it preferable for heavy-duty applications, while tin brass is favored for precision components requiring easy fabrication.

Corrosion Resistance Comparison

Tin bronze exhibits superior corrosion resistance compared to tin brass due to its higher tin content and copper alloy composition, which enhances its durability in marine and acidic environments. Tin brass, containing a lower percentage of tin and higher zinc content, is more prone to dezincification and corrosion, particularly in freshwater and alkaline conditions. The protective oxide layer formed in tin bronze significantly reduces metal degradation, making it preferable for applications requiring long-term exposure to corrosive elements.

Manufacturing Processes for Tin Bronze vs Tin Brass

Tin bronze manufacturing involves alloying copper with around 5-20% tin, often through casting or powder metallurgy processes that enhance wear resistance and corrosion performance. Tin brass production incorporates a lower tin content, typically up to 1-2%, with zinc as the primary alloying metal, using hot or cold working methods like rolling and forging to achieve desirable mechanical strength. Both alloys require precise control of temperature and cooling rates to optimize microstructure and prevent defects, impacting their respective applications in bearings and mechanical components.

Typical Applications in Industry

Tin bronze is widely used in heavy-load bearings, marine hardware, and gears due to its excellent corrosion resistance and strength. Tin brass finds typical applications in plumbing fittings, musical instruments, and decorative hardware, favored for its machinability and antimicrobial properties. Both alloys serve distinct industrial roles where their unique mechanical and chemical properties are crucial for performance and durability.

Cost Analysis: Tin Bronze vs Tin Brass

Tin bronze generally incurs a higher cost than tin brass due to its increased copper content and superior mechanical properties like corrosion resistance and strength. Tin brass, containing more zinc, is typically less expensive to produce and offers good machinability and moderate corrosion resistance at a lower price point. When analyzing cost-effectiveness, tin brass is favored for budget-conscious applications requiring adequate durability, while tin bronze is chosen for demanding environments justifying the higher investment.

Machinability and Fabrication

Tin bronze offers superior machinability compared to tin brass due to its controlled copper-tin alloy composition, resulting in less tool wear and smoother cutting performance. Fabrication processes such as casting and forging are more efficient with tin bronze, benefiting from its excellent fluidity and higher strength. Tin brass, while easier to form and mold, typically requires slower machining speeds and frequent tool maintenance due to its higher zinc content impacting chip formation.

Lifespan and Durability Factors

Tin bronze exhibits superior lifespan and durability due to its higher resistance to corrosion and wear, making it ideal for heavy-duty applications and marine environments. Tin brass, while offering better machinability and good strength, generally has a shorter lifespan under harsh conditions because it is more prone to dezincification and stress corrosion cracking. The durability of tin bronze is enhanced by its alloy composition, which provides a harder surface and improved fatigue resistance compared to tin brass.

Choosing the Right Alloy for Your Needs

Tin bronze offers superior corrosion resistance and strength due to its higher tin content, making it ideal for marine and industrial applications where durability is critical. Tin brass combines the workability of brass with improved corrosion resistance, suited for decorative items and electrical components requiring moderate strength and aesthetic appeal. Selecting between tin bronze and tin brass depends on the balance between mechanical performance, environmental exposure, and cost considerations specific to your project requirements.

Tin bronze vs Tin brass Infographic

materialdif.com

materialdif.com