Keyless canning eliminates the need for traditional welding by using advanced sealing technology that ensures a secure, airtight closure without metal joining. This method reduces contamination risks and improves the integrity of tin pet cans, making them ideal for preserving freshness and extending shelf life. Welded can seaming involves fusing metal edges, which can create weak points susceptible to corrosion, whereas keyless sealing offers a more consistent and durable barrier.

Table of Comparison

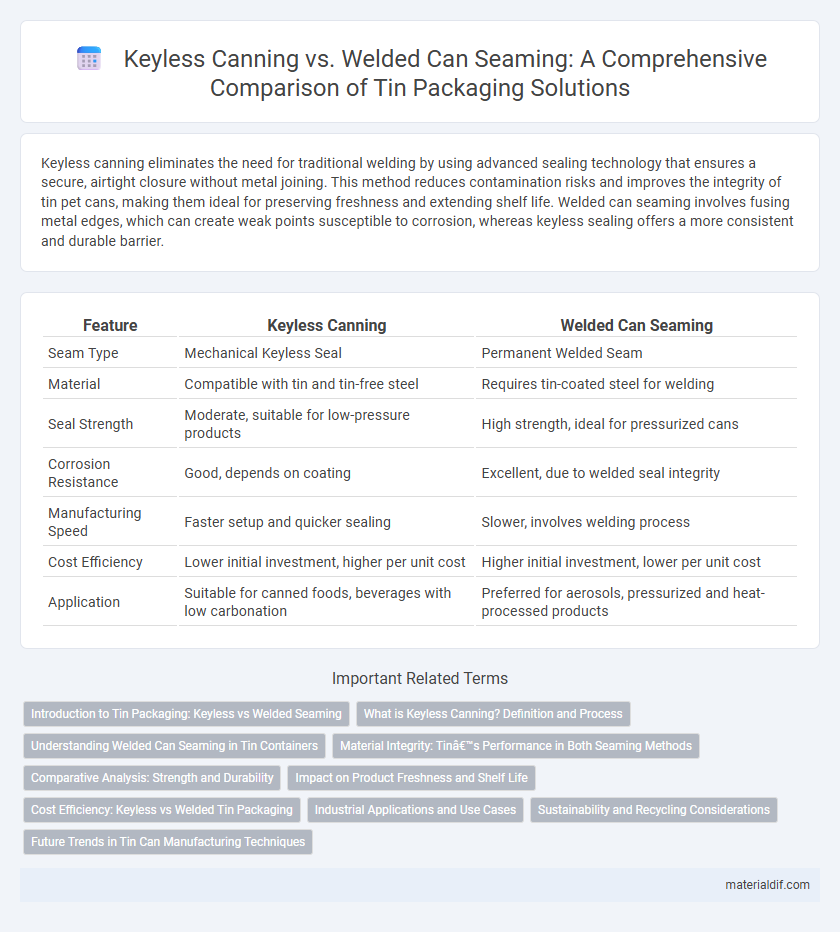

| Feature | Keyless Canning | Welded Can Seaming |

|---|---|---|

| Seam Type | Mechanical Keyless Seal | Permanent Welded Seam |

| Material | Compatible with tin and tin-free steel | Requires tin-coated steel for welding |

| Seal Strength | Moderate, suitable for low-pressure products | High strength, ideal for pressurized cans |

| Corrosion Resistance | Good, depends on coating | Excellent, due to welded seal integrity |

| Manufacturing Speed | Faster setup and quicker sealing | Slower, involves welding process |

| Cost Efficiency | Lower initial investment, higher per unit cost | Higher initial investment, lower per unit cost |

| Application | Suitable for canned foods, beverages with low carbonation | Preferred for aerosols, pressurized and heat-processed products |

Introduction to Tin Packaging: Keyless vs Welded Seaming

Tin packaging methods include keyless canning and welded can seaming, each offering unique benefits for product preservation and durability. Keyless cans utilize a press-on lid sealed without a separate key, enhancing tamper resistance and ease of opening, while welded seaming involves fusing metal edges to create a hermetic seal, providing superior structural integrity and leak prevention. Selection between these methods depends on product type, shelf-life requirements, and manufacturing efficiency in tin packaging processes.

What is Keyless Canning? Definition and Process

Keyless canning is a modern food packaging technique that eliminates the need for a separate lid by sealing the container without traditional seam welding. This process uses advanced machinery to create an airtight closure through pressure and heat, ensuring product preservation and contamination prevention. Keyless canning enhances efficiency by reducing materials and minimizing potential leak points compared to conventional welded can seaming methods.

Understanding Welded Can Seaming in Tin Containers

Welded can seaming in tin containers involves joining metal edges through precise heat and pressure to create a durable, airtight seal essential for preserving product freshness and preventing contamination. This method ensures superior structural integrity and corrosion resistance compared to keyless canning, particularly in high-pressure or vacuum-packed food products. Advancements in welding technology optimize seam strength and reduce the risk of leaks, enhancing overall container reliability in the tin packaging industry.

Material Integrity: Tin’s Performance in Both Seaming Methods

Tin's corrosion resistance plays a crucial role in maintaining material integrity during both keyless canning and welded can seaming processes. In keyless canning, tin coating prevents oxidation and preserves the seal without compromising the metal's surface, while welded can seaming relies on tin's ability to withstand high heat and pressure without degrading. The consistent performance of tin ensures long-term durability and preserves the containment quality essential for food and beverage packaging.

Comparative Analysis: Strength and Durability

Keyless canning offers enhanced structural integrity by eliminating weld seams prone to corrosion, resulting in a consistent metal bond that improves overall durability in tin packaging. Welded can seaming, while traditionally reliable, introduces potential weak points where stress and wear can cause seam failure under high pressure or impact. Comparative tests reveal that keyless cans withstand greater internal pressure and mechanical stress without compromising the tin's protective barrier, making them superior in applications demanding long-term strength and resistance.

Impact on Product Freshness and Shelf Life

Keyless canning eliminates the need for welding seams, reducing contamination risks and preserving product freshness by maintaining an airtight seal. Welded can seaming, while structurally robust, can introduce micro-gaps that compromise the hermetic barrier, potentially shortening shelf life. Studies show keyless cans extend shelf life by up to 30% due to enhanced prevention of oxidation and microbial ingress.

Cost Efficiency: Keyless vs Welded Tin Packaging

Keyless canning systems reduce material and labor costs by eliminating the need for additional sealing components, making them more cost-efficient than traditional welded tin seaming methods. Welded sealing requires precise alignment and specialized machinery, which increase production time and maintenance expenses. Overall, keyless tin packaging offers a streamlined process that lowers operational costs while maintaining product integrity.

Industrial Applications and Use Cases

Keyless canning offers significant advantages in industrial applications by eliminating the need for traditional weld seams, enhancing production speed and reducing contamination risks in food and beverage packaging. Welded can seaming remains preferred in heavy-duty and high-pressure environments, such as paint and chemical industries, where structural integrity and airtight seals are critical. The choice between keyless and welded seaming is driven by specific use cases, balancing factors like product type, shelf life, and manufacturing efficiency.

Sustainability and Recycling Considerations

Keyless canning eliminates the need for additional materials such as adhesives or sealants, reducing waste and enhancing tin can recyclability by ensuring cleaner separation of metal components. Welded can seaming, while providing strong joints, often involves coatings or liner materials that complicate recycling processes and increase environmental impact. Sustainable tin packaging solutions increasingly favor keyless designs to improve end-of-life tin recovery and minimize ecological footprints.

Future Trends in Tin Can Manufacturing Techniques

Future trends in tin can manufacturing emphasize keyless canning technologies, which streamline production by eliminating the need for separate key mechanisms while maintaining tin's corrosion resistance and recyclability. Welded can seaming advancements focus on enhancing seam integrity through laser welding and ultrasonic sealing, improving durability and reducing contamination risks in tin containers. Integration of smart sensors and AI-driven quality control is projected to optimize both keyless and welded seaming processes, promoting sustainability and efficiency in the tin can industry.

Keyless Canning vs Welded Can Seaming Infographic

materialdif.com

materialdif.com