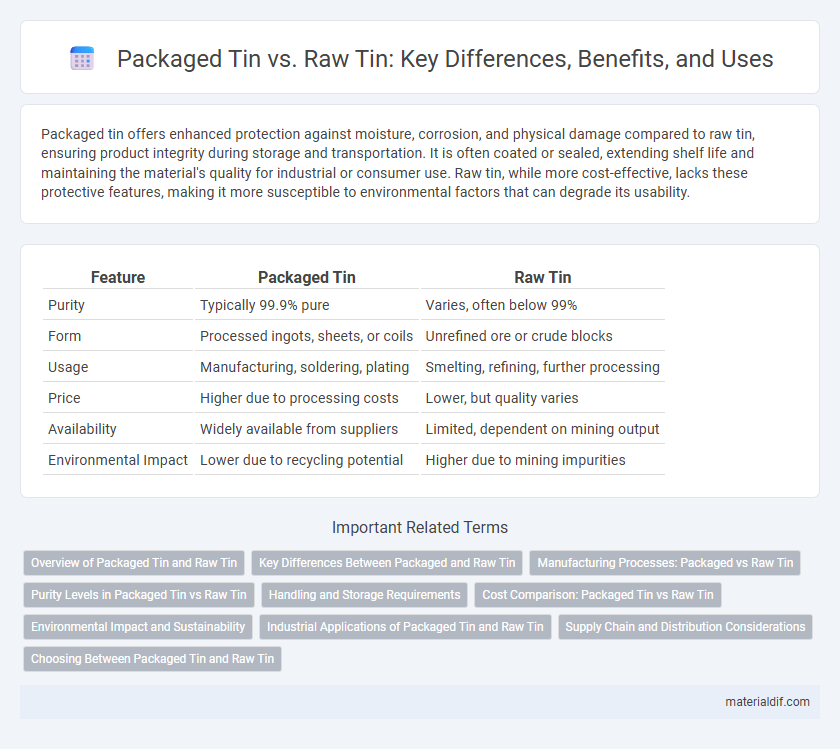

Packaged tin offers enhanced protection against moisture, corrosion, and physical damage compared to raw tin, ensuring product integrity during storage and transportation. It is often coated or sealed, extending shelf life and maintaining the material's quality for industrial or consumer use. Raw tin, while more cost-effective, lacks these protective features, making it more susceptible to environmental factors that can degrade its usability.

Table of Comparison

| Feature | Packaged Tin | Raw Tin |

|---|---|---|

| Purity | Typically 99.9% pure | Varies, often below 99% |

| Form | Processed ingots, sheets, or coils | Unrefined ore or crude blocks |

| Usage | Manufacturing, soldering, plating | Smelting, refining, further processing |

| Price | Higher due to processing costs | Lower, but quality varies |

| Availability | Widely available from suppliers | Limited, dependent on mining output |

| Environmental Impact | Lower due to recycling potential | Higher due to mining impurities |

Overview of Packaged Tin and Raw Tin

Packaged tin refers to tin that has been processed, refined, and compressed into standardized forms such as ingots, bars, or coils, facilitating easier storage, transport, and industrial use. Raw tin, on the other hand, is extracted directly from tin ore, primarily cassiterite, and contains impurities that require additional refining before commercial application. The distinction between packaged tin and raw tin significantly impacts supply chain efficiency and product quality in tin-dependent industries like electronics and solder manufacturing.

Key Differences Between Packaged and Raw Tin

Packaged tin offers enhanced protection against corrosion and contamination compared to raw tin, ensuring higher purity and quality during storage and transportation. Raw tin typically contains impurities and requires additional refining before industrial use, whereas packaged tin is processed and ready for manufacturing applications. The packaging also facilitates easier handling and precise inventory control, crucial for industries relying on consistent material specifications.

Manufacturing Processes: Packaged vs Raw Tin

Packaged tin undergoes extensive refining and alloying processes to ensure consistent purity and quality, making it ideal for precise manufacturing applications. Raw tin is extracted directly from cassiterite ore and requires additional purification steps, including smelting and chemical treatments, before it can be used in production. The manufacturing process for packaged tin includes casting into standardized forms such as ingots or sheets, facilitating easier handling and integration into industrial workflows.

Purity Levels in Packaged Tin vs Raw Tin

Packaged tin typically exhibits higher purity levels, often exceeding 99.9%, as it undergoes refining processes that remove impurities found in raw tin. Raw tin contains various contaminants such as iron, copper, and sulfur, resulting in lower overall purity, usually around 95-98%. The enhanced purity in packaged tin ensures better performance in electronics, soldering, and plating applications.

Handling and Storage Requirements

Packaged tin offers enhanced protection against oxidation and contamination, requiring less stringent storage conditions compared to raw tin, which must be kept in controlled environments to prevent degradation and corrosion. Proper humidity control and temperature regulation are critical for raw tin to maintain its purity and malleability. Packaged tin typically comes sealed in moisture-resistant materials, reducing the need for specialized handling equipment and minimizing exposure to environmental elements.

Cost Comparison: Packaged Tin vs Raw Tin

Packaged tin generally incurs higher costs than raw tin due to additional processing, packaging, and transportation expenses, which enhance product handling and shelf life. Raw tin, while lower in upfront cost, may require further refinement and processing, potentially increasing overall expenses in manufacturing. Cost efficiency depends on the specific application, volume, and supply chain logistics involved.

Environmental Impact and Sustainability

Packaged tin typically involves additional processing and transportation that increase its carbon footprint compared to raw tin, which is often sourced directly from mines with minimal refinement. Raw tin extraction can lead to significant environmental degradation, including habitat destruction and soil contamination, but sustainable mining practices and proper waste management can mitigate these effects. Choosing recycled or responsibly sourced packaged tin supports sustainability by reducing natural resource depletion and lowering greenhouse gas emissions in the supply chain.

Industrial Applications of Packaged Tin and Raw Tin

Packaged tin offers enhanced corrosion resistance and ease of handling, making it ideal for electronic soldering, plating, and alloy production in the automotive and aerospace industries. Raw tin, with its unprocessed form, is primarily used in large-scale industrial applications such as steel coating for corrosion protection and as a base material in tin refining. The choice between packaged and raw tin depends on the precision and purity requirements of specific industrial processes, impacting manufacturing efficiency and product quality.

Supply Chain and Distribution Considerations

Packaged tin offers advantages in supply chain efficiency by reducing handling damage and contamination risks during transportation compared to raw tin, which requires additional processing and quality checks upon arrival. Distribution networks benefit from standardized packaging that simplifies inventory management and accelerates delivery times to manufacturers. Raw tin's variability in form and purity often necessitates specialized storage and customized logistics, increasing overall operational complexity and costs.

Choosing Between Packaged Tin and Raw Tin

Choosing between packaged tin and raw tin depends on the intended industrial application and ease of handling requirements. Packaged tin offers enhanced protection against contamination, moisture, and oxidation, making it ideal for manufacturers prioritizing product quality and shelf life. Raw tin, while more cost-effective and suitable for bulk processing, requires stringent storage conditions to prevent degradation and may involve additional preparation steps before use.

Packaged Tin vs Raw Tin Infographic

materialdif.com

materialdif.com