Tin whiskers are microscopic, hair-like metallic filaments that grow spontaneously from tin surfaces, often causing electrical shorts in electronic components. Tin dendrites, in contrast, form branching, tree-like structures resulting from electrochemical plating processes, which can also lead to circuit failures but typically develop under different environmental conditions. Understanding the distinctions between tin whiskers and tin dendrites is crucial for improving the reliability and longevity of electronic assemblies.

Table of Comparison

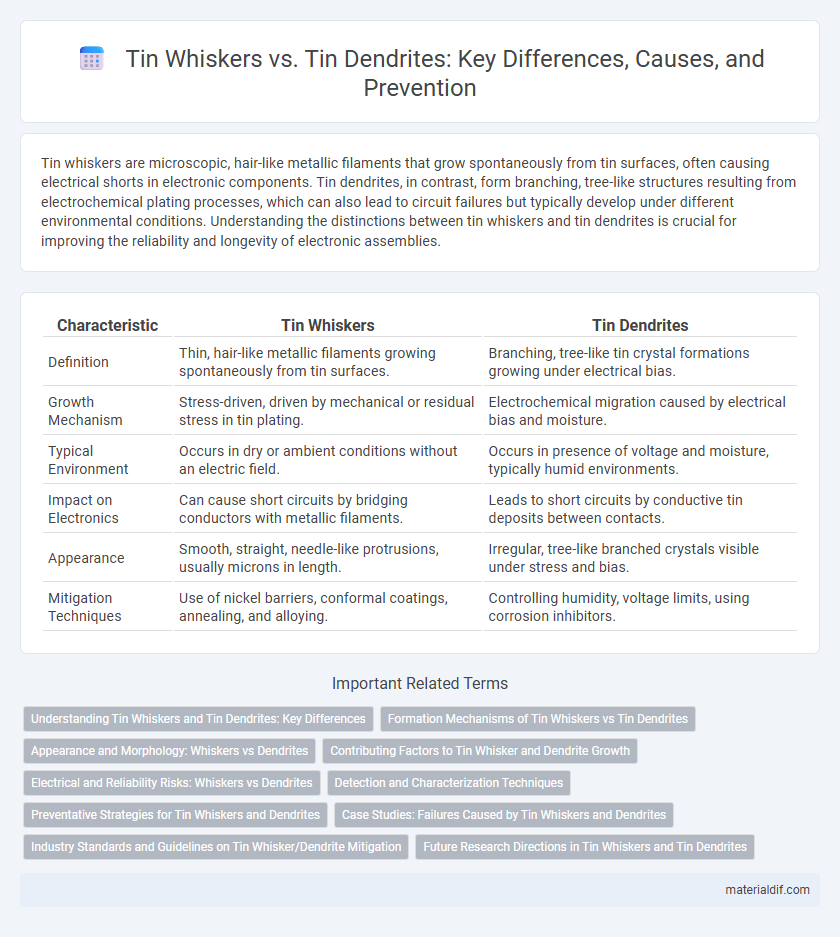

| Characteristic | Tin Whiskers | Tin Dendrites |

|---|---|---|

| Definition | Thin, hair-like metallic filaments growing spontaneously from tin surfaces. | Branching, tree-like tin crystal formations growing under electrical bias. |

| Growth Mechanism | Stress-driven, driven by mechanical or residual stress in tin plating. | Electrochemical migration caused by electrical bias and moisture. |

| Typical Environment | Occurs in dry or ambient conditions without an electric field. | Occurs in presence of voltage and moisture, typically humid environments. |

| Impact on Electronics | Can cause short circuits by bridging conductors with metallic filaments. | Leads to short circuits by conductive tin deposits between contacts. |

| Appearance | Smooth, straight, needle-like protrusions, usually microns in length. | Irregular, tree-like branched crystals visible under stress and bias. |

| Mitigation Techniques | Use of nickel barriers, conformal coatings, annealing, and alloying. | Controlling humidity, voltage limits, using corrosion inhibitors. |

Understanding Tin Whiskers and Tin Dendrites: Key Differences

Tin whiskers are hair-like metallic filaments that spontaneously grow from tin surfaces, causing short circuits in electronic components, whereas tin dendrites are branched, tree-like crystalline structures formed during electroplating or battery cycling. Both phenomena pose reliability risks in electronics, but whiskers primarily arise from mechanical stress and intermetallic growth, while dendrites result from ion migration under electrical fields. Understanding these differences aids in developing targeted mitigation strategies for enhancing electronic device longevity.

Formation Mechanisms of Tin Whiskers vs Tin Dendrites

Tin whiskers form primarily due to internal compressive stress within the tin plating, caused by factors like intermetallic compound growth and mechanical stress, leading to the spontaneous extrusion of thin, hair-like filaments. Tin dendrites develop via electrochemical deposition during tin plating or in the presence of an electric field and ionic species, resulting in branched, tree-like crystalline structures. The key difference in formation mechanisms lies in whiskers originating from stress-induced metal atom diffusion, whereas dendrites arise from electrochemical nucleation and growth processes.

Appearance and Morphology: Whiskers vs Dendrites

Tin whiskers are filament-like, hair-thin crystalline structures that grow up to several millimeters in length with a smooth, uniform cylindrical shape, often appearing straight or slightly curved. Tin dendrites exhibit a tree-like, branched morphology with complex, multi-directional growth patterns resembling tiny metallic coral formations. The key difference lies in whiskers' slender, needle-like structure compared to dendrites' bulky, intricate branching, impacting electrical reliability in electronic components.

Contributing Factors to Tin Whisker and Dendrite Growth

Tin whisker growth is primarily influenced by mechanical stress, such as residual stress from electroplating, thermal expansion mismatches, and external mechanical forces, which induce atomic diffusion and filament formation. Tin dendrites, in contrast, develop due to electrochemical conditions including high voltage, humidity, and ionic contamination, promoting electrochemical migration and branched crystal growth. Both phenomena are exacerbated by factors like environmental humidity, surface oxidation, and the presence of lead-free tin alloys, which affect microstructural stability and electrical reliability.

Electrical and Reliability Risks: Whiskers vs Dendrites

Tin whiskers are filament-like metallic growths that cause short circuits and signal interference due to their unpredictable paths, posing significant reliability risks in electronic components. Tin dendrites, branch-like crystalline structures formed from electrochemical migration, lead to conductive bridges and device failure under humid or high-voltage conditions. Both phenomena adversely affect electrical performance and long-term durability, with whiskers primarily causing mechanical shorts and dendrites contributing to corrosion and leakage currents.

Detection and Characterization Techniques

Detection and characterization of tin whiskers and dendrites rely heavily on advanced microscopy techniques such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM) for high-resolution surface imaging and structural analysis. X-ray diffraction (XRD) and focused ion beam (FIB) methods enable elemental composition and cross-sectional examinations, critical for distinguishing whiskers, which are filament-like crystalline growths, from dendrites, characterized by branch-like structures formed under electrochemical conditions. Spectroscopic techniques like energy-dispersive X-ray spectroscopy (EDS) supplement morphological data by confirming elemental purity and growth mechanisms.

Preventative Strategies for Tin Whiskers and Dendrites

Preventative strategies for tin whiskers include applying conformal coatings, using matte or alloyed tin finishes such as tin-silver or tin-copper, and implementing stress relief treatments to minimize mechanical stress. In contrast, tin dendrite prevention focuses on eliminating moisture sources and controlling electrochemical conditions by enhancing encapsulation and using corrosion inhibitors to reduce ionic migration. Both phenomena benefit from strict environmental controls and careful material selection to ensure long-term reliability in electronic assemblies.

Case Studies: Failures Caused by Tin Whiskers and Dendrites

Tin whiskers have caused significant failures in aerospace and telecommunications due to their ability to create short circuits in densely packed electronic assemblies. Case studies reveal that tin dendrites, often occurring in plated zinc and tin coatings, result in corrosion and eventual device malfunction in automotive battery components. Both phenomena emphasize the critical need for mitigation strategies such as conformal coatings and alloying with lead or bismuth to enhance electronic reliability.

Industry Standards and Guidelines on Tin Whisker/Dendrite Mitigation

Industry standards such as IPC-7093 and MIL-STD-883 provide comprehensive guidelines for mitigating tin whisker growth in electronic assemblies, emphasizing pure tin avoidance and the use of tin-lead or matte finishes. Tin dendrite mitigation aligns with controlling ionic contamination and humidity per IEC 60068-2 standards to prevent electrically conductive filament formation on printed circuit boards. Compliance with these standards ensures reliability and longevity in high-reliability sectors like aerospace and automotive electronics.

Future Research Directions in Tin Whiskers and Tin Dendrites

Future research in tin whiskers and tin dendrites will emphasize advanced characterization techniques using electron microscopy and in-situ stress analysis to better understand nucleation and growth mechanisms. Investigations into alloying elements, surface treatments, and multilayer coatings aim to develop reliable mitigation strategies for electronic component failure. The exploration of predictive modeling integrating machine learning with experimental data will optimize material design and failure prediction under diverse environmental conditions.

Tin whiskers vs tin dendrites Infographic

materialdif.com

materialdif.com