Flow-melted tin offers superior homogeneity and fewer impurities compared to static-melted tin, resulting in enhanced mechanical properties and conductivity. The dynamic movement during flow melting prevents oxide layer formation, ensuring a cleaner, more consistent alloy composition. This process improves the overall reliability and performance of tin in electronic and industrial applications.

Table of Comparison

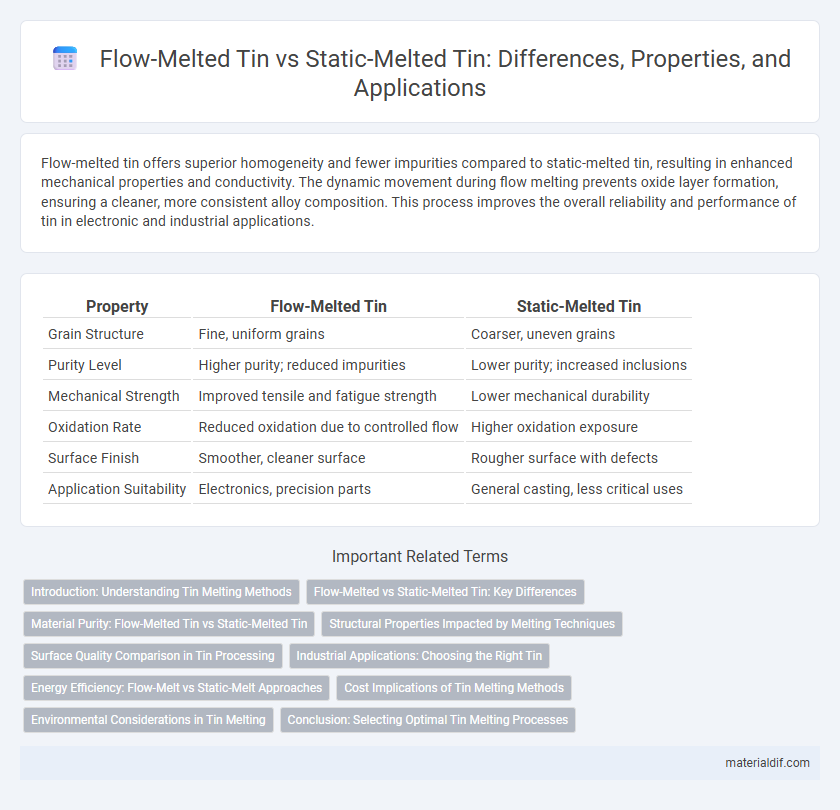

| Property | Flow-Melted Tin | Static-Melted Tin |

|---|---|---|

| Grain Structure | Fine, uniform grains | Coarser, uneven grains |

| Purity Level | Higher purity; reduced impurities | Lower purity; increased inclusions |

| Mechanical Strength | Improved tensile and fatigue strength | Lower mechanical durability |

| Oxidation Rate | Reduced oxidation due to controlled flow | Higher oxidation exposure |

| Surface Finish | Smoother, cleaner surface | Rougher surface with defects |

| Application Suitability | Electronics, precision parts | General casting, less critical uses |

Introduction: Understanding Tin Melting Methods

Flow-melted tin involves continuously melting and casting tin, resulting in a more homogeneous microstructure with fewer impurities compared to static-melted tin, which is melted in a stationary batch process. The dynamic nature of flow-melting enhances heat distribution and reduces oxidation, leading to improved material properties such as higher purity and better mechanical strength. Understanding these differences is crucial for applications requiring high-quality tin, such as in electronics soldering and tin plating.

Flow-Melted vs Static-Melted Tin: Key Differences

Flow-melted tin undergoes continuous refining during the melting process, resulting in higher purity levels and reduced oxide inclusions compared to static-melted tin, which is melted in a still condition. The dynamic flow in flow melting facilitates the removal of slag and contaminants, enhancing the metal's electrical conductivity and solderability. Static-melted tin typically contains more impurities and may exhibit lower mechanical performance due to less effective separation of non-metallic elements.

Material Purity: Flow-Melted Tin vs Static-Melted Tin

Flow-melted tin typically achieves higher material purity compared to static-melted tin due to continuous circulation that promotes uniform temperature distribution and reduced contamination. Static-melted tin often contains more impurities as the molten metal remains stationary, allowing sediment and non-metallic inclusions to accumulate. The enhanced purity in flow-melted tin results in better mechanical properties and improved performance in electronic and industrial applications.

Structural Properties Impacted by Melting Techniques

Flow-melted tin exhibits a more uniform crystalline structure with reduced grain boundaries compared to static-melted tin, which typically shows larger, uneven grain formations. The dynamic flow during melting promotes faster solidification rates, resulting in refined microstructures that enhance mechanical strength and electrical conductivity. Static melting often leads to segregation and porosity, negatively affecting the material's structural integrity and performance in electronic applications.

Surface Quality Comparison in Tin Processing

Flow-melted tin exhibits superior surface quality compared to static-melted tin due to enhanced impurity removal and uniform temperature distribution during processing. The dynamic flow ensures fewer oxide inclusions and minimizes surface roughness, resulting in a cleaner, smoother finish. Studies report that flow-melted tin achieves a surface defect reduction of up to 30%, improving reliability in electronic soldering applications.

Industrial Applications: Choosing the Right Tin

Flow-melted tin offers superior purity and uniformity compared to static-melted tin, making it ideal for high-precision industrial applications such as electronics soldering and specialty coatings. Its enhanced flow characteristics ensure consistent alloy composition and reduced impurities, which directly improve product reliability and performance. Industries requiring stringent quality standards and fine microstructures, such as semiconductor manufacturing, predominantly select flow-melted tin to optimize manufacturing outcomes.

Energy Efficiency: Flow-Melt vs Static-Melt Approaches

Flow-melted tin processes demonstrate higher energy efficiency compared to static-melted tin methods due to enhanced heat transfer and reduced thermal losses. The continuous circulation in flow melting promotes uniform temperature distribution, minimizing energy consumption during the melting phase. Static melting often requires prolonged heating with greater energy input to achieve consistent molten tin quality.

Cost Implications of Tin Melting Methods

Flow-melted tin typically incurs higher energy and equipment costs compared to static-melted tin due to continuous circulation and advanced temperature control systems. However, it offers improved purity and reduced dross formation, potentially lowering long-term material losses and refining expenses. Static-melted tin requires less operational complexity and initial investment, making it more cost-effective for small-scale production but may result in increased wastage and lower overall yield.

Environmental Considerations in Tin Melting

Flow-melted tin significantly reduces energy consumption compared to static-melted tin by maintaining a consistent temperature and preventing overheating, which lowers greenhouse gas emissions. The controlled flow process minimizes dross formation, decreasing material waste and environmental contamination. Efficient energy use and reduced waste make flow-melted tin a more sustainable choice in tin melting operations.

Conclusion: Selecting Optimal Tin Melting Processes

Flow-melted tin demonstrates superior uniformity and reduced impurity levels compared to static-melted tin, resulting in enhanced mechanical properties and corrosion resistance. Optimizing tin melting processes by using flow methods increases product consistency and reduces defects, crucial for high-performance electronic and solder applications. Choosing flow-melted tin aligns with industrial demands for reliability and quality in advanced manufacturing.

flow-melted tin vs static-melted tin Infographic

materialdif.com

materialdif.com