Tin-plated steel involves applying a thin layer of tin directly onto steel through a hot-dip or electroplating process, offering corrosion resistance and a smooth surface ideal for packaging. Electrolytic tinplate, produced by electroplating tin onto cleaned steel sheets, provides a more uniform coating and superior adhesion, enhancing durability and corrosion protection. Both materials are widely used in can manufacturing, but electrolytic tinplate is preferred for high-quality, food-grade applications due to its consistent finish and safety standards.

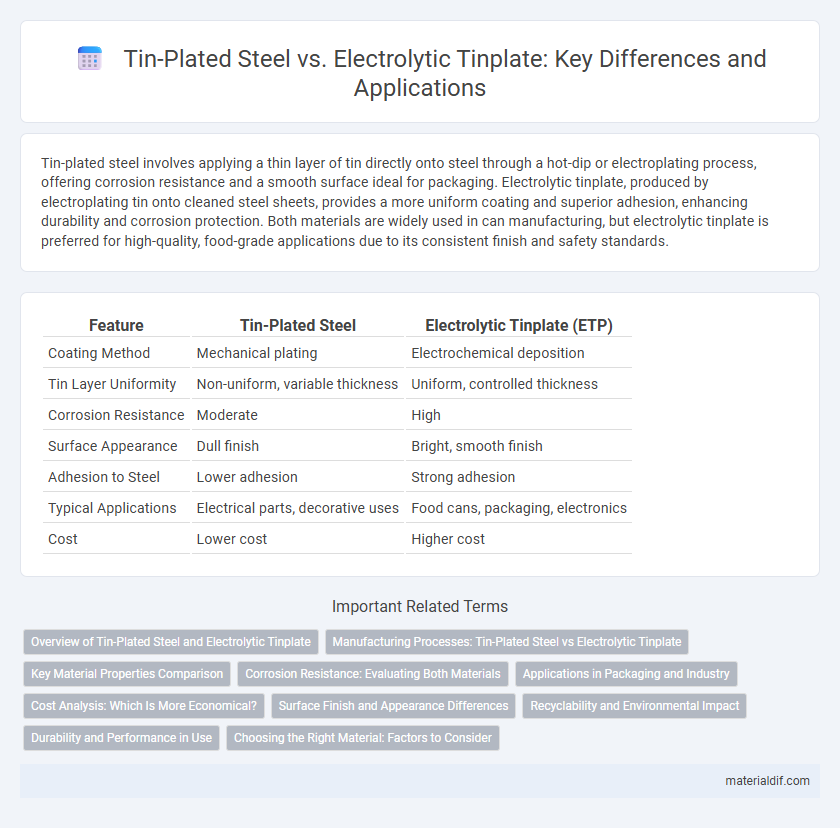

Table of Comparison

| Feature | Tin-Plated Steel | Electrolytic Tinplate (ETP) |

|---|---|---|

| Coating Method | Mechanical plating | Electrochemical deposition |

| Tin Layer Uniformity | Non-uniform, variable thickness | Uniform, controlled thickness |

| Corrosion Resistance | Moderate | High |

| Surface Appearance | Dull finish | Bright, smooth finish |

| Adhesion to Steel | Lower adhesion | Strong adhesion |

| Typical Applications | Electrical parts, decorative uses | Food cans, packaging, electronics |

| Cost | Lower cost | Higher cost |

Overview of Tin-Plated Steel and Electrolytic Tinplate

Tin-plated steel is a material produced by coating steel with a thin layer of tin to enhance corrosion resistance and improve solderability, commonly used in packaging and automotive applications. Electrolytic tinplate is a specific type of tin-plated steel where the tin coating is applied through an electrochemical process, ensuring a uniform, smooth, and highly controlled tin layer that boosts aesthetics and corrosion protection. The electrolytic process allows precise coating thickness, resulting in superior barrier properties compared to traditional hot-dip tin plating methods.

Manufacturing Processes: Tin-Plated Steel vs Electrolytic Tinplate

Tin-plated steel is produced by hot-dipping steel sheets into molten tin, creating a thick corrosion-resistant coating with excellent adhesion. Electrolytic tinplate involves an electrochemical process where a thin, uniform layer of tin is deposited onto steel through electrolysis, enhancing precision and surface finish. The manufacturing choice impacts the tin layer's thickness, coating consistency, and overall corrosion protection performance.

Key Material Properties Comparison

Tin-plated steel features a thin layer of tin applied through mechanical or chemical methods, offering moderate corrosion resistance and excellent solderability. Electrolytic tinplate is produced by electroplating tin onto cold-rolled steel, resulting in a uniform, durable coating with superior corrosion protection and enhanced surface smoothness. Key material properties such as adhesion strength, surface finish, and resistance to oxidation are significantly improved in electrolytic tinplate compared to conventional tin-plated steel.

Corrosion Resistance: Evaluating Both Materials

Tin-plated steel and electrolytic tinplate differ significantly in corrosion resistance due to their coating processes. Electrolytic tinplate offers a uniform, thin layer of tin deposited via electrolysis, providing superior protection against oxidation and moisture compared to traditional tin-plated steel, which often has a thicker but less consistent tin layer. This precise control in electrolytic tinplate enhances longevity and performance in harsh environments, making it ideal for food packaging and industrial applications where corrosion resistance is critical.

Applications in Packaging and Industry

Tin-plated steel offers superior corrosion resistance and is widely used in packaging applications such as food and beverage cans due to its non-toxic properties and durability. Electrolytic tinplate, produced through an electroplating process, provides a smooth, uniform coating ideal for high-quality packaging requiring enhanced surface finish and printability. Both materials find industrial use in electrical components and automotive parts, where their protective coatings extend product lifespan and improve performance.

Cost Analysis: Which Is More Economical?

Tin-plated steel generally offers a lower initial cost due to simpler plating processes and less stringent quality controls compared to electrolytic tinplate, which involves a more precise electrochemical deposition resulting in higher production expenses. Electrolytic tinplate provides superior corrosion resistance and uniform coating thickness, potentially reducing long-term maintenance and replacement costs despite its higher upfront price. Choosing between the two depends on balancing immediate budget constraints against the anticipated durability and performance benefits in specific industrial applications.

Surface Finish and Appearance Differences

Tin-plated steel features a thicker, uneven tin coating that results in a more matte surface finish, while electrolytic tinplate (ETP) offers a uniform, smooth, and highly reflective appearance due to its precise electro-deposition process. The surface of ETP is typically brighter and more corrosion-resistant, enhancing both aesthetic appeal and functional durability in applications like food packaging. In contrast, tin-plated steel's less controlled coating thickness can lead to variations in sheen and surface texture, impacting visual consistency and performance.

Recyclability and Environmental Impact

Tin-plated steel, created through the hot-dip process, offers robust recyclability by facilitating easy separation of steel and tin during recycling, reducing environmental waste. Electrolytic tinplate, produced via electro-deposition, uses less tin and generates fewer emissions, minimizing its environmental footprint while maintaining excellent corrosion resistance. Both materials support sustainable metal recovery, yet electrolytic tinplate's energy-efficient production provides a greener alternative in packaging and manufacturing applications.

Durability and Performance in Use

Tin-plated steel offers a corrosion-resistant surface ideal for packaging and industrial applications, while electrolytic tinplate provides a more uniform and thinner coating that enhances durability and printability. Electrolytic tinplate exhibits superior adhesion and wear resistance, resulting in longer-lasting protection against rust and mechanical damage. The controlled electrochemical deposition process ensures consistent performance, making electrolytic tinplate preferable for high-quality, durable consumer goods.

Choosing the Right Material: Factors to Consider

When choosing between tin-plated steel and electrolytic tinplate, consider corrosion resistance, surface uniformity, and intended application. Electrolytic tinplate offers a smoother, more uniform coating ideal for food packaging due to its superior corrosion protection and aesthetic appeal. Tin-plated steel, often produced via hot-dipping, provides thicker coatings suitable for industrial uses where durability and cost-effectiveness are prioritized.

Tin-plated steel vs Electrolytic tinplate Infographic

materialdif.com

materialdif.com