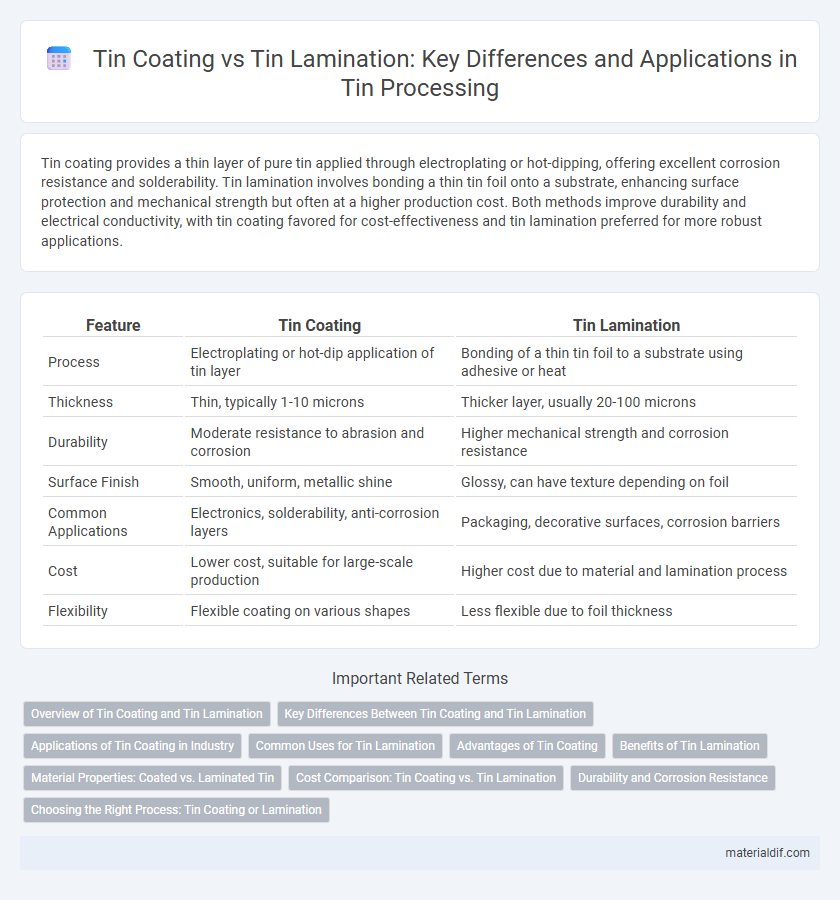

Tin coating provides a thin layer of pure tin applied through electroplating or hot-dipping, offering excellent corrosion resistance and solderability. Tin lamination involves bonding a thin tin foil onto a substrate, enhancing surface protection and mechanical strength but often at a higher production cost. Both methods improve durability and electrical conductivity, with tin coating favored for cost-effectiveness and tin lamination preferred for more robust applications.

Table of Comparison

| Feature | Tin Coating | Tin Lamination |

|---|---|---|

| Process | Electroplating or hot-dip application of tin layer | Bonding of a thin tin foil to a substrate using adhesive or heat |

| Thickness | Thin, typically 1-10 microns | Thicker layer, usually 20-100 microns |

| Durability | Moderate resistance to abrasion and corrosion | Higher mechanical strength and corrosion resistance |

| Surface Finish | Smooth, uniform, metallic shine | Glossy, can have texture depending on foil |

| Common Applications | Electronics, solderability, anti-corrosion layers | Packaging, decorative surfaces, corrosion barriers |

| Cost | Lower cost, suitable for large-scale production | Higher cost due to material and lamination process |

| Flexibility | Flexible coating on various shapes | Less flexible due to foil thickness |

Overview of Tin Coating and Tin Lamination

Tin coating involves applying a thin layer of tin onto a substrate to enhance corrosion resistance and solderability, commonly used in electronics and food packaging. Tin lamination, on the other hand, refers to bonding a tin foil layer onto materials like paperboard for improved barrier properties and printability, widely utilized in packaging applications. Both processes leverage tin's anti-corrosive and conductive properties but differ significantly in application technique and end-use performance.

Key Differences Between Tin Coating and Tin Lamination

Tin coating involves applying a thin layer of tin directly onto a metal surface through electroplating or hot-dip methods, enhancing corrosion resistance and solderability. Tin lamination, however, entails bonding a pre-coated tin foil onto a substrate, providing thicker protection and improved mechanical strength. The key differences lie in application techniques, layer thickness, and the resulting durability and cost-effectiveness for industrial uses.

Applications of Tin Coating in Industry

Tin coating is extensively utilized in the electronics industry to protect copper components from oxidation and improve solderability in printed circuit boards (PCBs). In the food packaging sector, tin-coated steel ensures corrosion resistance and food safety by preventing metal contamination. Automotive manufacturers employ tin coatings on steel parts to enhance corrosion resistance and extend the lifespan of critical components exposed to harsh environments.

Common Uses for Tin Lamination

Tin lamination is widely used in the food packaging industry, providing a durable, corrosion-resistant barrier that preserves product freshness and extends shelf life. It is also commonly employed in electronic components, where its excellent solderability and protection against oxidation enhance the reliability and longevity of circuit boards. The versatility of tin lamination in creating thin, protective layers makes it a preferred choice for packaging metal sheets and enhancing surface quality in manufacturing.

Advantages of Tin Coating

Tin coating offers superior corrosion resistance by creating a protective barrier that prevents rust and oxidation on metal surfaces. Its uniform application ensures consistent conductivity and solderability, making it ideal for electronic components. Tin coating also enhances durability and extends the lifespan of metals without significantly increasing weight or thickness.

Benefits of Tin Lamination

Tin lamination provides superior corrosion resistance compared to tin coating, ensuring enhanced durability for electronic components and packaging materials. It offers improved adhesion and mechanical strength, resulting in longer-lasting protection against environmental factors such as moisture and oxidation. The precise layer control in tin lamination reduces material waste and enhances overall product quality, making it a cost-effective solution for industrial applications.

Material Properties: Coated vs. Laminated Tin

Tin coating provides a thin, uniform layer of pure tin that enhances corrosion resistance and electrical conductivity while maintaining the substrate's original flexibility and form. Tin lamination involves bonding a thicker, multilayered tin foil onto a substrate, offering superior mechanical strength, improved barrier protection, and increased durability under extreme environmental conditions. Coated tin typically excels in applications requiring fine surface finish and conductivity, whereas laminated tin is preferred for structural stability and enhanced protection against physical wear.

Cost Comparison: Tin Coating vs. Tin Lamination

Tin coating generally incurs lower material and processing costs compared to tin lamination due to simpler application techniques such as electroplating or hot-dipping. Tin lamination involves bonding a pre-coated tin foil to a substrate, which increases labor and equipment expenses, resulting in higher overall production costs. Cost efficiency is more pronounced in tin coating for large-scale manufacturing where thin, uniform layers suffice, while tin lamination suits applications requiring thicker, protective layers despite its premium price.

Durability and Corrosion Resistance

Tin coating provides a thin layer of pure tin applied through electroplating, offering excellent corrosion resistance and moderate durability suitable for protecting metal substrates. Tin lamination involves bonding a thicker tin foil or sheet to the surface, resulting in superior mechanical durability and enhanced protection against physical damage and corrosion over prolonged exposure. While tin lamination generally delivers longer-lasting corrosion resistance due to its substantial barrier, tin coating remains effective for applications requiring thinner, more uniform protective layers.

Choosing the Right Process: Tin Coating or Lamination

Choosing between tin coating and tin lamination depends on the specific application requirements and environmental conditions. Tin coating provides excellent corrosion resistance and solderability for electronic components, while tin lamination offers superior mechanical strength and durability for packaging materials. Evaluating factors such as cost, thickness, adhesion, and end-use environment ensures the optimal process selection for performance and longevity.

tin coating vs tin lamination Infographic

materialdif.com

materialdif.com