Annealed tinplate offers enhanced ductility and flexibility due to its heat-treatment process, making it ideal for intricate forming and packaging applications. Tempered tinplate, on the other hand, undergoes controlled cooling that increases its strength and hardness, providing superior resistance to dents and deformation. Choosing between annealed and tempered tinplate depends on the specific requirements of durability versus formability in tin pet production.

Table of Comparison

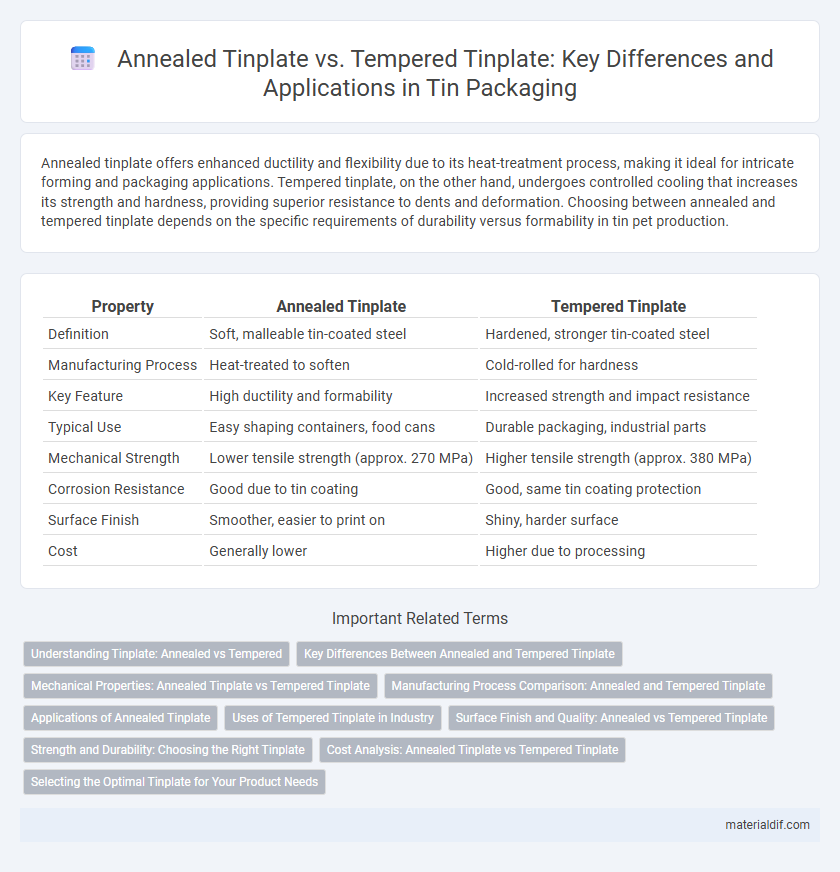

| Property | Annealed Tinplate | Tempered Tinplate |

|---|---|---|

| Definition | Soft, malleable tin-coated steel | Hardened, stronger tin-coated steel |

| Manufacturing Process | Heat-treated to soften | Cold-rolled for hardness |

| Key Feature | High ductility and formability | Increased strength and impact resistance |

| Typical Use | Easy shaping containers, food cans | Durable packaging, industrial parts |

| Mechanical Strength | Lower tensile strength (approx. 270 MPa) | Higher tensile strength (approx. 380 MPa) |

| Corrosion Resistance | Good due to tin coating | Good, same tin coating protection |

| Surface Finish | Smoother, easier to print on | Shiny, harder surface |

| Cost | Generally lower | Higher due to processing |

Understanding Tinplate: Annealed vs Tempered

Annealed tinplate features a soft, ductile steel base coated with tin, enabling superior formability and ease of fabrication in packaging applications. Tempered tinplate undergoes controlled heat treatment to enhance hardness and mechanical strength, offering improved resistance to abrasion and denting. Choosing between annealed and tempered tinplate depends on the desired balance between flexibility and durability for specific industrial uses.

Key Differences Between Annealed and Tempered Tinplate

Annealed tinplate undergoes a heat treatment process that renders it soft and pliable, making it ideal for intricate forming and deep drawing applications, whereas tempered tinplate is cooled rapidly to enhance its hardness and strength for better durability. The key difference lies in the mechanical properties, where annealed tinplate offers superior ductility and tempering provides increased stiffness and impact resistance. These distinctions influence their respective uses in packaging, with annealed tinplate favored for easy shaping and tempered tinplate preferred for structural integrity.

Mechanical Properties: Annealed Tinplate vs Tempered Tinplate

Annealed tinplate exhibits increased ductility and softness due to its heat treatment process, enabling superior formability and ease of shaping. In contrast, tempered tinplate undergoes a controlled cooling process that enhances its strength, hardness, and resistance to deformation under mechanical stress. The mechanical property differences make annealed tinplate ideal for deep drawing applications, while tempered tinplate is preferred for applications requiring higher tensile strength and durability.

Manufacturing Process Comparison: Annealed and Tempered Tinplate

Annealed tinplate undergoes a heat treatment process where it is heated to a specific temperature and then slowly cooled to relieve internal stresses, resulting in a softer and more ductile metal suitable for deep drawing and forming. Tempered tinplate is subjected to a rapid cooling or quenching process after cold rolling, which increases its strength and hardness by creating a more rigid grain structure. The difference in manufacturing processes directly impacts the mechanical properties and end-use applications, with annealed tinplate favored for containers requiring flexibility and tempered tinplate for applications demanding higher tensile strength.

Applications of Annealed Tinplate

Annealed tinplate is widely used in food and beverage cans due to its excellent formability and corrosion resistance, making it ideal for packaging delicate products. Its softness allows for easier deep drawing and shaping processes in manufacturing industries, particularly for aerosol containers, paint cans, and decorative applications. The metallurgical properties of annealed tinplate provide superior weldability and paint adhesion compared to tempered tinplate, enhancing its functionality in consumer goods production.

Uses of Tempered Tinplate in Industry

Tempered tinplate is widely used in the packaging industry for manufacturing durable food cans, beverage containers, and aerosol cans due to its enhanced strength and corrosion resistance. Its superior mechanical properties make it ideal for applications requiring repeated handling, such as automotive parts and electrical components. The industrial use of tempered tinplate extends to household appliances and construction materials, where its rigidity and protective coating ensure long-term performance.

Surface Finish and Quality: Annealed vs Tempered Tinplate

Annealed tinplate features a smooth, bright surface finish achieved through heat treatment, enhancing its ductility and ease of forming without compromising corrosion resistance. Tempered tinplate undergoes a cold rolling process that produces a harder, more durable surface with increased strength but reduced flexibility, making it ideal for applications requiring improved mechanical performance. The choice between annealed and tempered tinplate depends on the balance between surface quality, formability, and mechanical properties needed for specific industrial uses.

Strength and Durability: Choosing the Right Tinplate

Annealed tinplate offers enhanced ductility and ease of forming due to its softened state, making it suitable for applications requiring intricate shaping but with moderate strength. Tempered tinplate undergoes a heat treatment process that significantly increases its tensile strength and durability, ideal for packaging that demands resistance to impacts and deformation. Selecting between annealed and tempered tinplate depends primarily on the necessary balance between formability and mechanical robustness in the final product.

Cost Analysis: Annealed Tinplate vs Tempered Tinplate

Annealed tinplate generally offers lower production costs compared to tempered tinplate due to its softer, more malleable nature, which requires less energy during manufacturing. Tempered tinplate incurs higher expenses owing to additional heat treatment processes that enhance its strength and durability, resulting in increased processing time and energy consumption. Cost analysis reveals annealed tinplate is more economical for applications prioritizing formability, while tempered tinplate demands a premium justified by its superior mechanical properties.

Selecting the Optimal Tinplate for Your Product Needs

Annealed tinplate offers superior malleability and ease of forming, making it ideal for packaging applications requiring complex shapes or deep drawing. Tempered tinplate provides higher strength and stiffness, suitable for products demanding durability and resistance to deformation during handling and processing. Assessing product requirements such as flexibility, strength, and manufacturing methods is crucial for selecting the optimal tinplate type that ensures performance and cost-efficiency.

Annealed Tinplate vs Tempered Tinplate Infographic

materialdif.com

materialdif.com