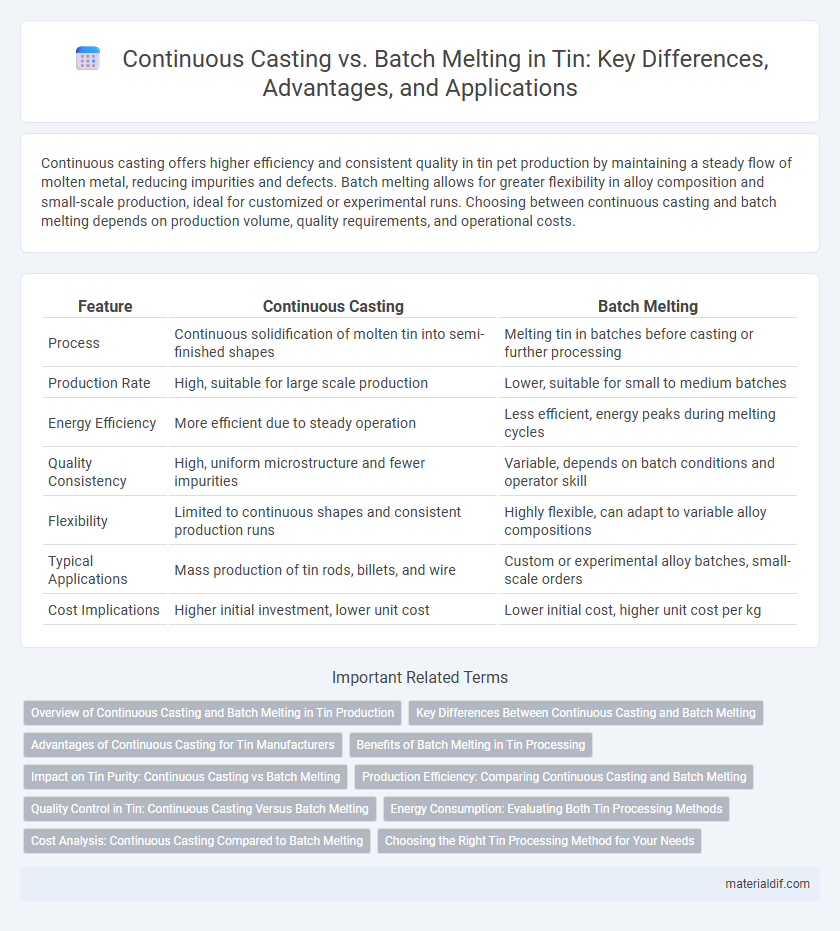

Continuous casting offers higher efficiency and consistent quality in tin pet production by maintaining a steady flow of molten metal, reducing impurities and defects. Batch melting allows for greater flexibility in alloy composition and small-scale production, ideal for customized or experimental runs. Choosing between continuous casting and batch melting depends on production volume, quality requirements, and operational costs.

Table of Comparison

| Feature | Continuous Casting | Batch Melting |

|---|---|---|

| Process | Continuous solidification of molten tin into semi-finished shapes | Melting tin in batches before casting or further processing |

| Production Rate | High, suitable for large scale production | Lower, suitable for small to medium batches |

| Energy Efficiency | More efficient due to steady operation | Less efficient, energy peaks during melting cycles |

| Quality Consistency | High, uniform microstructure and fewer impurities | Variable, depends on batch conditions and operator skill |

| Flexibility | Limited to continuous shapes and consistent production runs | Highly flexible, can adapt to variable alloy compositions |

| Typical Applications | Mass production of tin rods, billets, and wire | Custom or experimental alloy batches, small-scale orders |

| Cost Implications | Higher initial investment, lower unit cost | Lower initial cost, higher unit cost per kg |

Overview of Continuous Casting and Batch Melting in Tin Production

Continuous casting in tin production involves a streamlined process where molten tin is solidified directly into semi-finished shapes, enhancing efficiency and reducing energy consumption. Batch melting, by contrast, processes smaller, discrete quantities of tin with more flexibility but higher energy use and longer production cycles. Continuous casting offers consistent quality and scalability, making it ideal for large-scale tin manufacturing.

Key Differences Between Continuous Casting and Batch Melting

Continuous casting in tin production involves the continuous solidification of molten metal into a semi-finished billet, allowing for high efficiency and consistent product quality, while batch melting processes tin in discrete quantities, leading to variability in temperature control and energy consumption. Continuous casting reduces defects such as porosity and segregation due to steady cooling rates, whereas batch melting may experience uneven cooling and higher oxidation risks. The continuous casting method optimizes material utilization and throughput, making it preferable for large-scale tin manufacturing compared to the intermittent and labor-intensive batch melting approach.

Advantages of Continuous Casting for Tin Manufacturers

Continuous casting enhances tin production efficiency by enabling a streamlined, uninterrupted flow of molten metal, reducing energy consumption and minimizing wastage compared to batch melting. This method improves the quality and consistency of tin products by maintaining stable temperature control and reducing oxidation risks during solidification. Tin manufacturers benefit from higher throughput and lower operational costs, making continuous casting a preferred choice for large-scale production.

Benefits of Batch Melting in Tin Processing

Batch melting in tin processing offers precise temperature control, which ensures uniform alloy composition and minimizes oxidation losses. This method allows for better quality management and flexibility in handling different tin grades or scrap materials, enhancing overall product consistency. Improved energy efficiency and ease of maintenance also make batch melting a cost-effective option compared to continuous casting.

Impact on Tin Purity: Continuous Casting vs Batch Melting

Continuous casting significantly enhances tin purity by minimizing exposure to contaminants and reducing oxidation during solidification, resulting in fewer impurities and a more uniform microstructure. Batch melting, in contrast, involves holding molten tin for extended periods, increasing the risk of oxidation and contamination, which can degrade tin quality. The controlled environment of continuous casting ensures higher consistency and purity levels essential for high-grade tin applications.

Production Efficiency: Comparing Continuous Casting and Batch Melting

Continuous casting of tin significantly improves production efficiency by enabling a steady, uninterrupted flow of molten metal, reducing cycle times and minimizing energy consumption per unit produced. Batch melting involves distinct melting and cooling phases, causing frequent stops and longer processing times, leading to lower throughput and higher operational costs. Continuous casting optimizes resource utilization and streamlines the manufacturing process, making it the preferred method for high-volume tin production.

Quality Control in Tin: Continuous Casting Versus Batch Melting

Continuous casting of tin offers superior quality control by maintaining a consistent temperature and reducing oxidation risks, resulting in uniform grain structure and fewer impurities. Batch melting often suffers from temperature fluctuations and increased exposure to contaminants, leading to variable product quality and higher defect rates. Continuous casting enhances repeatability and precision in tin production, crucial for applications requiring high-purity and optimal mechanical properties.

Energy Consumption: Evaluating Both Tin Processing Methods

Continuous casting of tin significantly reduces energy consumption by maintaining a steady molten state, minimizing reheating cycles compared to batch melting, which requires frequent melting of separate batches. Batch melting involves higher thermal losses due to repeated heating and cooling phases, resulting in increased fuel usage and longer processing times. Energy efficiency in continuous casting improves tin yield and lowers operational costs, making it the preferred method for large-scale tin production.

Cost Analysis: Continuous Casting Compared to Batch Melting

Continuous casting of tin significantly reduces operational costs due to lower energy consumption and minimized material wastage compared to batch melting processes. The continuous casting method streamlines production by maintaining steady furnace temperatures, leading to enhanced energy efficiency and reduced labor expenses. Batch melting incurs higher costs from frequent reheating cycles and increased downtime, resulting in diminished overall cost-effectiveness.

Choosing the Right Tin Processing Method for Your Needs

Continuous casting offers superior efficiency and consistent quality for large-scale tin production, reducing energy consumption and minimizing waste compared to batch melting. Batch melting provides greater flexibility for smaller batches and specialized alloys, allowing precise control over composition and temperature during processing. Selecting the appropriate tin processing method depends on production volume, alloy requirements, and cost considerations to optimize performance and yield.

Continuous Casting vs Batch Melting Infographic

materialdif.com

materialdif.com