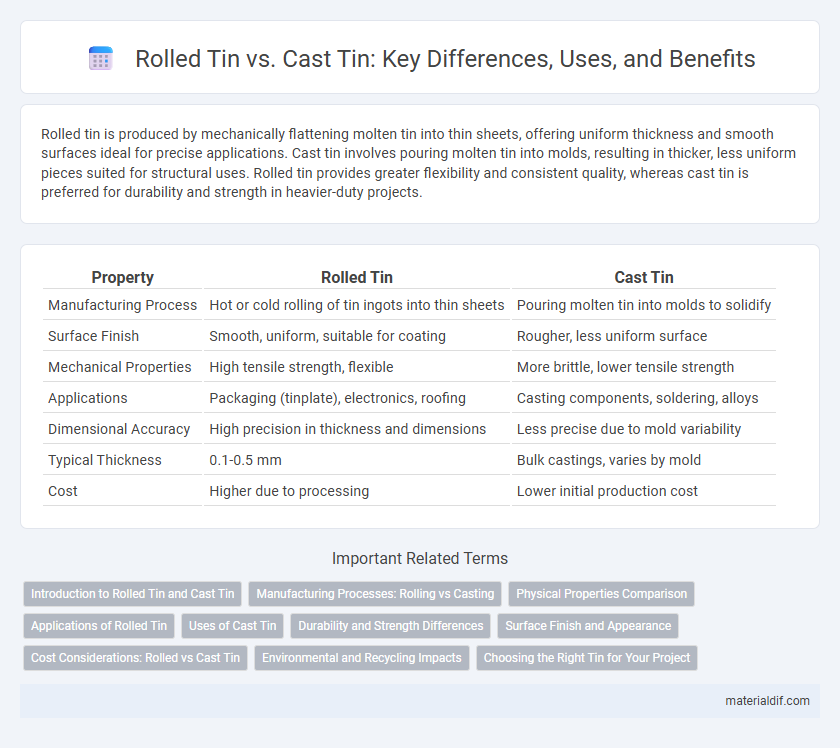

Rolled tin is produced by mechanically flattening molten tin into thin sheets, offering uniform thickness and smooth surfaces ideal for precise applications. Cast tin involves pouring molten tin into molds, resulting in thicker, less uniform pieces suited for structural uses. Rolled tin provides greater flexibility and consistent quality, whereas cast tin is preferred for durability and strength in heavier-duty projects.

Table of Comparison

| Property | Rolled Tin | Cast Tin |

|---|---|---|

| Manufacturing Process | Hot or cold rolling of tin ingots into thin sheets | Pouring molten tin into molds to solidify |

| Surface Finish | Smooth, uniform, suitable for coating | Rougher, less uniform surface |

| Mechanical Properties | High tensile strength, flexible | More brittle, lower tensile strength |

| Applications | Packaging (tinplate), electronics, roofing | Casting components, soldering, alloys |

| Dimensional Accuracy | High precision in thickness and dimensions | Less precise due to mold variability |

| Typical Thickness | 0.1-0.5 mm | Bulk castings, varies by mold |

| Cost | Higher due to processing | Lower initial production cost |

Introduction to Rolled Tin and Cast Tin

Rolled tin is produced by compressing and flattening tin ingots through a rolling process, resulting in a thin, uniform sheet used extensively in packaging, electronics, and tinplate production. Cast tin is created by melting tin and pouring it into molds to solidify into specific shapes or ingots, commonly utilized for manufacturing components requiring precise dimensions and purity. The distinction between rolled tin and cast tin lies in their fabrication methods and end-use applications, with rolled tin favored for flexible, sheet-based uses and cast tin for structural and raw material purposes.

Manufacturing Processes: Rolling vs Casting

Rolled tin is produced by passing molten tin through heavy rollers to create thin sheets with uniform thickness and smooth surfaces, optimizing it for applications requiring precise dimensions and flexibility. Cast tin is formed by pouring molten tin into molds, resulting in thicker, solid shapes with varied textures suitable for structural or ornamental uses. The rolling process emphasizes enhanced mechanical properties and surface finish, while casting offers design versatility and simpler production for bulkier items.

Physical Properties Comparison

Rolled tin exhibits a more uniform grain structure and enhanced mechanical strength compared to cast tin, resulting in superior ductility and toughness. Cast tin typically presents a coarser microstructure with increased brittleness and lower tensile strength, limiting its application where flexibility is critical. Thermal conductivity remains relatively consistent in both forms, but rolled tin's refined grain boundaries improve resistance to thermal fatigue and deformation.

Applications of Rolled Tin

Rolled tin is widely used in industries requiring flexible, thin sheets such as packaging, roofing, and electronics due to its excellent malleability and corrosion resistance. Its precision thickness and smooth surface make it ideal for manufacturing tinplate for food cans, decorative coatings, and soldering applications. Compared to cast tin, rolled tin offers superior uniformity and adaptability, enhancing its suitability for commercial and industrial uses.

Uses of Cast Tin

Cast tin is primarily used in applications requiring complex shapes and detailed designs, such as in the production of tin cans, decorative items, and electrical components. Its high purity and excellent corrosion resistance make it ideal for food packaging and soldering materials. The casting process allows for precise control over thickness and form, enhancing its suitability for specialized industrial uses.

Durability and Strength Differences

Rolled tin exhibits enhanced durability and superior tensile strength due to its metal grain alignment achieved through mechanical rolling, making it less prone to fractures under stress compared to cast tin. Cast tin, formed by solidifying molten metal in molds, has a more granular microstructure that often results in brittleness and lower impact resistance. The manufacturing process of rolled tin ensures better flexibility and resistance to wear, which is crucial for applications requiring prolonged mechanical endurance.

Surface Finish and Appearance

Rolled tin features a smooth, uniform surface finish resulting from cold rolling, which enhances its reflective appearance and makes it ideal for decorative applications. Cast tin, produced by pouring molten metal into molds, typically displays a rougher, less consistent surface with visible grain patterns. The choice between rolled and cast tin significantly affects the material's aesthetic qualities and suitability for specific visual or functional uses.

Cost Considerations: Rolled vs Cast Tin

Rolled tin generally incurs higher production costs due to the extensive mechanical processing involved, resulting in a finer grain structure and improved surface finish preferable for electronic applications. Cast tin boasts lower manufacturing expenses as it solidifies directly from molten metal, making it more cost-effective for bulk uses like plating and soldering. Cost considerations must weigh the balance between the superior mechanical properties of rolled tin and the affordability and scalability of cast tin production.

Environmental and Recycling Impacts

Rolled tin, produced through mechanical deformation, consumes less energy and generates fewer emissions than cast tin, which requires higher temperatures for melting and solidification. The recyclability of rolled tin is superior due to its uniform grain structure, facilitating easier remelting and reuse without significant quality loss. Cast tin, while durable, often contains impurities that complicate recycling processes and increase environmental impact.

Choosing the Right Tin for Your Project

Rolled tin offers superior surface smoothness and uniform thickness, making it ideal for precise applications like food packaging and electronics. Cast tin features a coarser grain structure, providing enhanced strength and durability suitable for industrial uses such as soldering and alloy production. Selecting rolled or cast tin depends on project requirements for surface finish quality versus mechanical robustness.

Rolled Tin vs Cast Tin Infographic

materialdif.com

materialdif.com