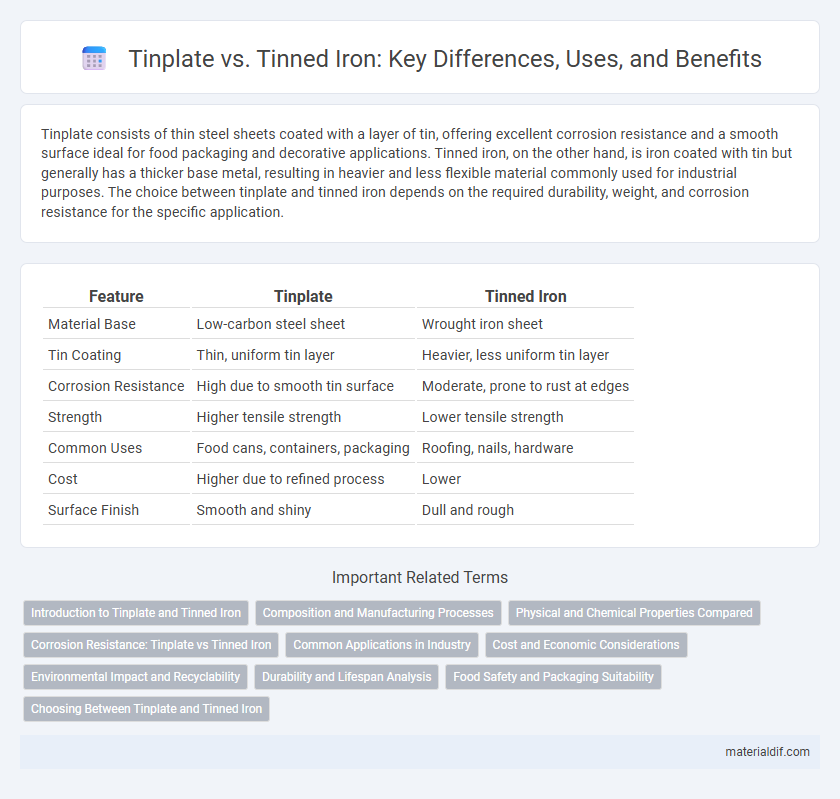

Tinplate consists of thin steel sheets coated with a layer of tin, offering excellent corrosion resistance and a smooth surface ideal for food packaging and decorative applications. Tinned iron, on the other hand, is iron coated with tin but generally has a thicker base metal, resulting in heavier and less flexible material commonly used for industrial purposes. The choice between tinplate and tinned iron depends on the required durability, weight, and corrosion resistance for the specific application.

Table of Comparison

| Feature | Tinplate | Tinned Iron |

|---|---|---|

| Material Base | Low-carbon steel sheet | Wrought iron sheet |

| Tin Coating | Thin, uniform tin layer | Heavier, less uniform tin layer |

| Corrosion Resistance | High due to smooth tin surface | Moderate, prone to rust at edges |

| Strength | Higher tensile strength | Lower tensile strength |

| Common Uses | Food cans, containers, packaging | Roofing, nails, hardware |

| Cost | Higher due to refined process | Lower |

| Surface Finish | Smooth and shiny | Dull and rough |

Introduction to Tinplate and Tinned Iron

Tinplate is a thin sheet of steel coated with a layer of tin to enhance corrosion resistance and provide a smooth surface for printing and packaging, commonly used in food cans and containers. Tinned iron, on the other hand, refers to iron or low-grade steel coated with tin, primarily to prevent rusting and extend the material's lifespan in industrial applications. The key difference lies in the base metal quality and the precision of coating processes, where tinplate offers superior durability and aesthetic qualities compared to more utilitarian tinned iron.

Composition and Manufacturing Processes

Tinplate consists of thin steel sheets coated with tin through electroplating, ensuring a smooth, corrosion-resistant surface ideal for food packaging and containers. Tinned iron involves iron sheets coated with tin using hot-dipping, a process where the iron is submerged in molten tin to create a thicker, more robust coating. The electroplating in tinplate yields a more uniform tin layer, while hot-dipping in tinned iron offers greater corrosion resistance but usually results in a less consistent coating thickness.

Physical and Chemical Properties Compared

Tinplate exhibits a smooth, corrosion-resistant surface due to its thin tin coating electrolytically applied over mild steel, enhancing its chemical stability and malleability compared to tinned iron. Tinned iron features a thicker layer of tin applied via mechanical dipping, resulting in greater brittleness and lower formability but improved resistance to oxidation and galvanic corrosion. Physically, tinplate offers superior ductility and a more uniform finish, while chemically, both materials provide effective protection against rust through the sacrificial properties of tin, though tinplate's controlled coating thickness ensures consistent performance.

Corrosion Resistance: Tinplate vs Tinned Iron

Tinplate offers superior corrosion resistance compared to tinned iron due to its thin, uniform coating of tin tightly bonded to the steel substrate, preventing moisture and oxygen from reaching the metal beneath. Tinned iron typically has a thicker but less uniform tin layer, making it more susceptible to localized corrosion and rust formation over time. The enhanced corrosion barrier of tinplate makes it ideal for food packaging and other applications where prolonged exposure to moisture is common.

Common Applications in Industry

Tinplate, composed of thin steel sheets coated with tin, is widely used in the packaging industry for food and beverage cans due to its corrosion resistance and food safety. Tinned iron, which involves tin coating on wrought iron or mild steel, finds applications in electrical components and decorative items where enhanced conductivity and rust protection are crucial. Both materials serve critical roles in preserving product integrity and extending the lifespan of industrial components.

Cost and Economic Considerations

Tinplate typically costs more than tinned iron due to its higher quality steel substrate and superior corrosion resistance, making it ideal for packaging applications like food cans. Tinned iron, with a cheaper iron base and thinner tin coating, offers a cost-effective alternative but sacrifices durability and longevity. Economic considerations favor tinplate for premium products where longevity and protection justify the higher expense, while tinned iron suits budget-conscious uses requiring minimal corrosion resistance.

Environmental Impact and Recyclability

Tinplate, composed of thin steel coated with tin, offers superior recyclability due to its homogeneous metal layers, enabling efficient recovery in steel recycling streams and reducing landfill waste. Tinned iron, often formed by electroplating tin onto wrought iron, presents challenges in recycling because the mixed metal composition complicates separation processes, potentially increasing environmental pollution. The environmental impact of tinplate is generally lower, as its recyclability conserves resources and reduces energy consumption compared to the less sustainable disposal and processing methods required for tinned iron.

Durability and Lifespan Analysis

Tinplate exhibits superior durability compared to tinned iron due to its thin steel sheet coated with a uniform layer of tin, which resists corrosion and extends lifespan significantly in packaging applications. Tinned iron, while also coated with tin, often features a thicker, less uniform layer prone to wear and rusting under prolonged exposure to moisture, resulting in a shorter service life. Therefore, tinplate is preferred in food packaging and industrial uses requiring long-term corrosion resistance and structural integrity.

Food Safety and Packaging Suitability

Tinplate offers superior corrosion resistance and a smoother surface compared to tinned iron, making it more suitable for food packaging by preventing contamination and extending shelf life. The thin layer of tin on tinplate acts as a robust barrier against acidic and alkaline food products, ensuring food safety and maintaining taste integrity. Tinned iron, with its uneven tin coating, is less reliable for long-term food storage as it is prone to corrosion and contamination risks.

Choosing Between Tinplate and Tinned Iron

Choosing between tinplate and tinned iron depends on the desired corrosion resistance and application requirements; tinplate is steel coated with a thin layer of tin, offering excellent rust prevention for food packaging and decorative uses. Tinned iron involves a heavier tin coating, providing enhanced protection against oxidation and is ideal for industrial applications subjected to harsher environments. Evaluating factors such as mechanical strength, cost, and environmental exposure helps determine the most suitable material for specific manufacturing needs.

Tinplate vs Tinned Iron Infographic

materialdif.com

materialdif.com