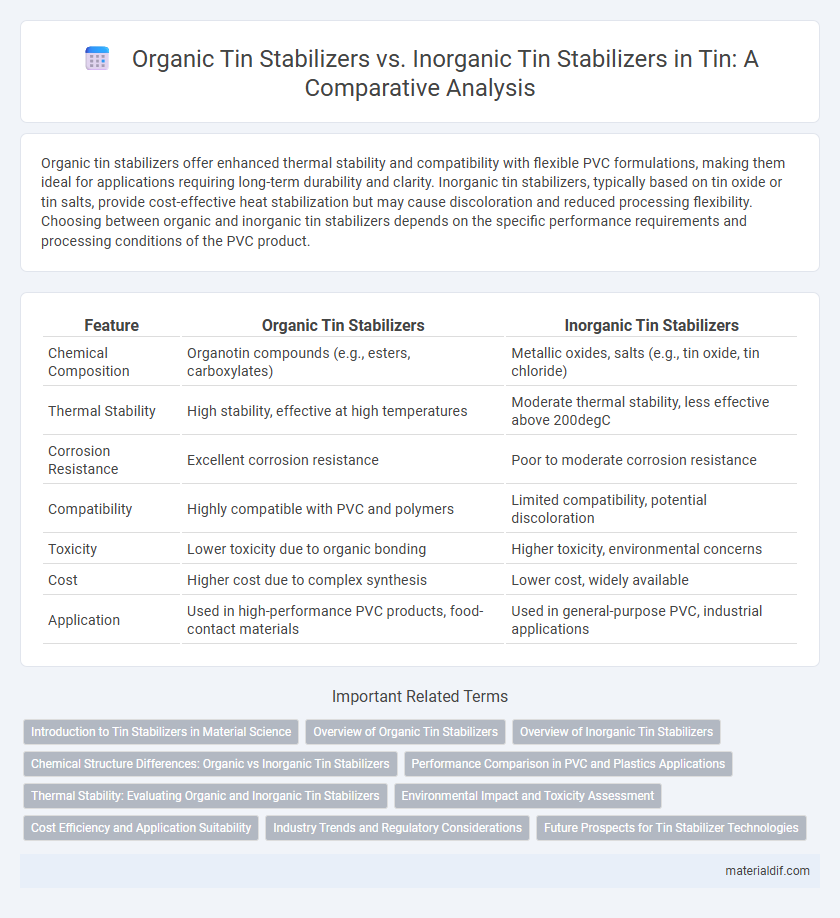

Organic tin stabilizers offer enhanced thermal stability and compatibility with flexible PVC formulations, making them ideal for applications requiring long-term durability and clarity. Inorganic tin stabilizers, typically based on tin oxide or tin salts, provide cost-effective heat stabilization but may cause discoloration and reduced processing flexibility. Choosing between organic and inorganic tin stabilizers depends on the specific performance requirements and processing conditions of the PVC product.

Table of Comparison

| Feature | Organic Tin Stabilizers | Inorganic Tin Stabilizers |

|---|---|---|

| Chemical Composition | Organotin compounds (e.g., esters, carboxylates) | Metallic oxides, salts (e.g., tin oxide, tin chloride) |

| Thermal Stability | High stability, effective at high temperatures | Moderate thermal stability, less effective above 200degC |

| Corrosion Resistance | Excellent corrosion resistance | Poor to moderate corrosion resistance |

| Compatibility | Highly compatible with PVC and polymers | Limited compatibility, potential discoloration |

| Toxicity | Lower toxicity due to organic bonding | Higher toxicity, environmental concerns |

| Cost | Higher cost due to complex synthesis | Lower cost, widely available |

| Application | Used in high-performance PVC products, food-contact materials | Used in general-purpose PVC, industrial applications |

Introduction to Tin Stabilizers in Material Science

Tin stabilizers are essential additives in polymer processing, enhancing thermal stability and durability; organic tin stabilizers, such as dibutyltin dilaurate, offer superior compatibility and processing efficiency, while inorganic tin stabilizers provide cost-effective alternatives with distinct thermal properties. Organic tin stabilizers typically excel in flexible PVC applications due to their improved heat resistance and transparency, whereas inorganic counterparts are favored in rigid formulations for their robust stabilizing effects. The choice between organic and inorganic tin stabilizers in material science depends on specific polymer requirements, processing conditions, and desired end-use performance.

Overview of Organic Tin Stabilizers

Organic tin stabilizers are widely used in PVC processing to enhance thermal stability and prevent degradation during manufacturing. These stabilizers typically consist of organotin compounds such as dibutyltin dilaurate or dioctyltin maleate, which provide excellent heat resistance and transparency compared to inorganic counterparts. Their effectiveness in maintaining polymer clarity and flexibility makes them essential in applications requiring high-performance PVC products.

Overview of Inorganic Tin Stabilizers

Inorganic tin stabilizers primarily consist of compounds like stannous chloride and stannic oxide, which offer excellent thermal stability and resistance to discoloration in PVC processing. These stabilizers function by neutralizing hydrochloric acid released during polymer degradation, enhancing the polymer's heat resistance and lifespan. Compared to organic tin stabilizers, inorganic variants provide a more cost-effective solution with lower toxicity but may exhibit less compatibility with certain plasticizers and processing conditions.

Chemical Structure Differences: Organic vs Inorganic Tin Stabilizers

Organic tin stabilizers contain tin atoms bonded to carbon-based groups, typically featuring alkyl or aryl ligands that enhance compatibility and dispersion in polymer matrices. Inorganic tin stabilizers, in contrast, consist of tin atoms linked to non-carbon elements such as oxygen, chlorine, or sulfur, forming salts or oxides that provide thermal stability through ionic or coordination bonds. These chemical structure differences influence their stabilization mechanisms, processing temperatures, and effectiveness in PVC applications.

Performance Comparison in PVC and Plastics Applications

Organic tin stabilizers typically offer superior thermal stability and clarity in PVC and plastics applications compared to inorganic tin stabilizers, enhancing long-term durability and color retention. Inorganic tin stabilizers, while more cost-effective and providing good initial heat resistance, often lag in overall performance under prolonged thermal and UV exposure. The choice between organic and inorganic tin stabilizers depends on the balance of processing conditions, end-use requirements, and material compatibility within PVC formulations.

Thermal Stability: Evaluating Organic and Inorganic Tin Stabilizers

Organic tin stabilizers offer superior thermal stability in PVC applications, maintaining performance at elevated temperatures up to 250degC, whereas inorganic tin stabilizers typically degrade or lose effectiveness beyond 200degC. The molecular structure of organic tin compounds enables them to better resist thermal decomposition and prevent PVC discoloration during processing. In contrast, inorganic tin stabilizers, such as stannates, provide more limited thermal stability but are preferred for cost-sensitive applications.

Environmental Impact and Toxicity Assessment

Organic tin stabilizers generally exhibit lower toxicity levels and reduced environmental persistence compared to inorganic tin stabilizers, which often contain heavy metals and exhibit higher bioaccumulation potential. Environmental impact assessments highlight that organic tin compounds degrade more readily, minimizing soil and water contamination risks, whereas inorganic tin stabilizers contribute to long-term ecological harm due to their resistance to breakdown. Toxicity studies confirm that organic tin stabilizers pose less threat to aquatic life and human health, making them a more sustainable choice in PVC stabilization applications.

Cost Efficiency and Application Suitability

Organic tin stabilizers offer superior cost efficiency in flexible PVC applications due to their lower processing temperatures and enhanced heat stability, reducing energy consumption and production costs. Inorganic tin stabilizers, while generally more affordable initially, require higher processing temperatures and are better suited for rigid PVC products, emphasizing durability over cost savings. Selecting the optimal stabilizer depends on balancing budget constraints with the specific application requirements, with organic options preferred for cost-sensitive, flexible uses and inorganic for cost-effective, rigid applications.

Industry Trends and Regulatory Considerations

Organic tin stabilizers, primarily used in PVC production, exhibit superior heat stability and environmental compliance compared to inorganic tin stabilizers, which are increasingly scrutinized due to potential heavy metal content. Industry trends indicate a growing preference for organic variants to meet stringent global regulations such as REACH and RoHS, emphasizing reduced toxicity and enhanced sustainability. Regulatory bodies are pushing for phase-outs of inorganic stabilizers in favor of eco-friendly alternatives, driving manufacturers to innovate formulations that balance performance with environmental safety.

Future Prospects for Tin Stabilizer Technologies

Organic tin stabilizers, primarily used in PVC processing, exhibit superior heat stability and transparency compared to inorganic tin stabilizers, which offer cost-effective solutions but with limited performance. Future prospects indicate a shift towards hybrid stabilizers combining organic and inorganic components to enhance environmental compatibility and processing efficiency. Innovations in bio-based and nano-enabled tin stabilizers are poised to reduce toxicity and improve sustainability in tin stabilizer technologies.

Organic tin stabilizers vs Inorganic tin stabilizers Infographic

materialdif.com

materialdif.com