Tin is a chemical element used primarily for its corrosion resistance and malleability, while tinning refers to the process of coating a metal surface with a thin layer of tin to protect it from rust and enhance conductivity. Tin pet containers are often tin-plated steel, combining the strength of steel with the protective benefits of tinning. This combination extends the lifespan of the container and ensures safe storage for food and other products.

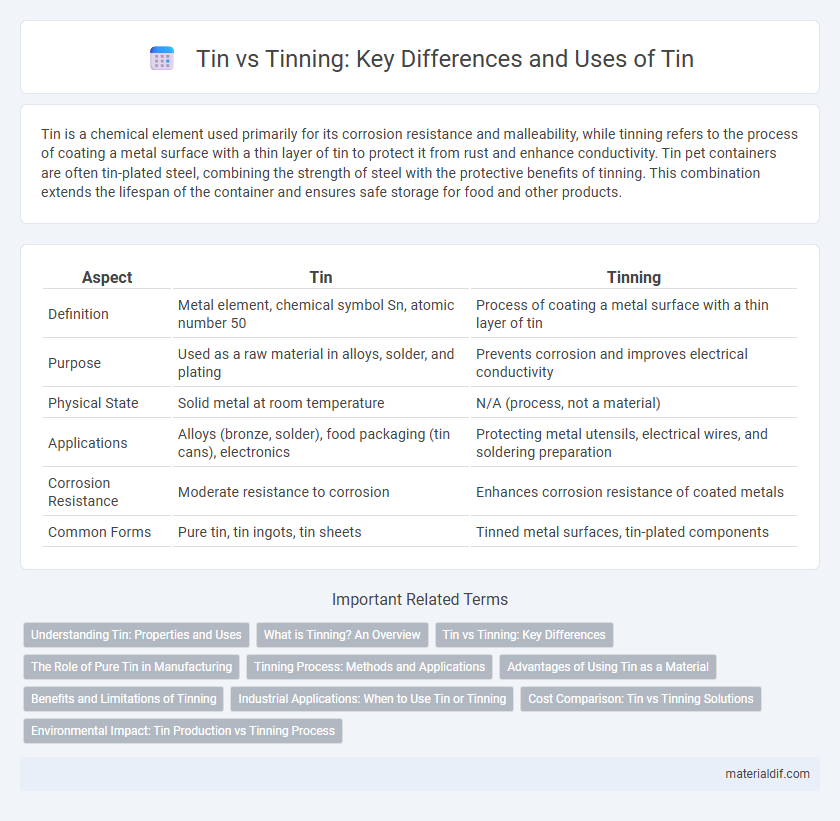

Table of Comparison

| Aspect | Tin | Tinning |

|---|---|---|

| Definition | Metal element, chemical symbol Sn, atomic number 50 | Process of coating a metal surface with a thin layer of tin |

| Purpose | Used as a raw material in alloys, solder, and plating | Prevents corrosion and improves electrical conductivity |

| Physical State | Solid metal at room temperature | N/A (process, not a material) |

| Applications | Alloys (bronze, solder), food packaging (tin cans), electronics | Protecting metal utensils, electrical wires, and soldering preparation |

| Corrosion Resistance | Moderate resistance to corrosion | Enhances corrosion resistance of coated metals |

| Common Forms | Pure tin, tin ingots, tin sheets | Tinned metal surfaces, tin-plated components |

Understanding Tin: Properties and Uses

Tin is a malleable, silvery-white metal known for its corrosion resistance and low melting point of 231.9degC, making it ideal for applications in soldering, plating, and alloy production. Tinning refers to the process of coating other metals, usually iron or steel, with a thin layer of tin to prevent rust and improve durability, commonly used in food packaging and electrical components. Understanding tin's properties, such as its non-toxic nature and excellent conductivity, highlights its widespread use in electronics, coatings, and various industrial applications.

What is Tinning? An Overview

Tinning is the process of coating a metal surface, typically iron or copper, with a thin layer of tin to prevent corrosion and enhance solderability. This technique improves metal durability in electrical components, cookware, and packaging by providing a protective, non-toxic barrier. In contrast, tin refers to the pure chemical element (Sn) used both as a standalone metal and as the coating material applied during tinning.

Tin vs Tinning: Key Differences

Tin is a chemical element with the symbol Sn and atomic number 50, known for its malleability and resistance to corrosion. Tinning refers to the process of coating a metal surface, typically steel or copper, with a thin layer of tin to prevent corrosion and improve solderability. The key difference lies in tin being the raw metallic element itself, while tinning describes the practical application of tin as a protective or conductive coating.

The Role of Pure Tin in Manufacturing

Pure tin plays a crucial role in manufacturing by serving as a primary material for coatings that protect metals from corrosion. Unlike tinning, which is the process of applying a thin layer of tin alloy to a substrate, pure tin offers superior solderability and electrical conductivity essential in electronics production. Its use in electronic components, such as printed circuit boards, enhances durability and performance by providing reliable, oxidation-resistant surfaces.

Tinning Process: Methods and Applications

Tinning is the process of coating a metal surface, usually steel or copper, with a thin layer of tin to prevent corrosion and improve solderability. Common tinning methods include hot-dip tinning, electroplating, and mechanical rolling, each offering specific benefits for industries like electronics, food packaging, and cookware. Applications of tinning extend to enhancing electrical conductivity and protecting metal components from oxidation, making it essential in manufacturing durable and reliable metal products.

Advantages of Using Tin as a Material

Tin offers excellent corrosion resistance, making it ideal for protecting metals from rust and deterioration. Its low toxicity and non-reactive nature ensure it is safe for use in food packaging and medical applications. The metal's malleability and solderability enhance manufacturing efficiency, providing strong, durable joins without compromising material integrity.

Benefits and Limitations of Tinning

Tinning enhances corrosion resistance by coating metals with a thin layer of tin, making it ideal for protecting iron and steel from rust. This process improves solderability, ensuring stronger and more reliable electrical connections in electronic components. Limitations include the potential for tin whisker formation, which can cause short circuits, and the thin coating's vulnerability to mechanical wear over time.

Industrial Applications: When to Use Tin or Tinning

Tin is a versatile metal widely used for its corrosion resistance and conductivity in industrial applications such as plating and alloy production. Tinning refers to the process of coating other metals with a thin layer of tin, enhancing surface durability, preventing oxidation, and improving solderability in electronics and automotive industries. Choosing between tin and tinning depends on whether the application requires the inherent properties of pure tin or the protective benefits offered by a tin coating on base metals.

Cost Comparison: Tin vs Tinning Solutions

Tin as a raw material generally has a higher upfront cost compared to tinning processes, which utilize a thin layer of tin coating over base metals to reduce expenses. Tinning solutions, involving electrolytic or chemical deposition, offer cost-effective alternatives by minimizing the amount of tin used while maintaining corrosion resistance and solderability. For industries prioritizing budget efficiency, tinning solutions provide economic advantages without compromising the protective properties associated with pure tin.

Environmental Impact: Tin Production vs Tinning Process

Tin production involves mining and smelting, which contribute significantly to deforestation, soil erosion, and water contamination due to heavy metal runoff. The tinning process, which coats metals with a thin layer of tin, has a substantially lower environmental footprint as it requires less energy and raw material extraction. Reducing reliance on primary tin mining by optimizing the tinning process can mitigate the overall environmental impact in the supply chain.

Tin vs Tinning Infographic

materialdif.com

materialdif.com