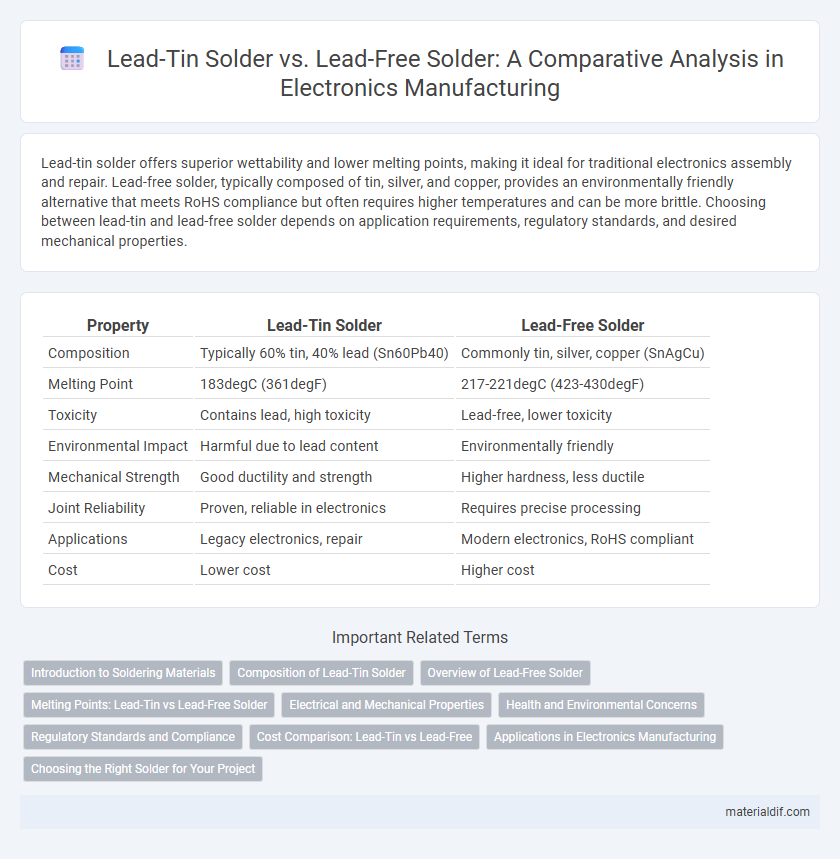

Lead-tin solder offers superior wettability and lower melting points, making it ideal for traditional electronics assembly and repair. Lead-free solder, typically composed of tin, silver, and copper, provides an environmentally friendly alternative that meets RoHS compliance but often requires higher temperatures and can be more brittle. Choosing between lead-tin and lead-free solder depends on application requirements, regulatory standards, and desired mechanical properties.

Table of Comparison

| Property | Lead-Tin Solder | Lead-Free Solder |

|---|---|---|

| Composition | Typically 60% tin, 40% lead (Sn60Pb40) | Commonly tin, silver, copper (SnAgCu) |

| Melting Point | 183degC (361degF) | 217-221degC (423-430degF) |

| Toxicity | Contains lead, high toxicity | Lead-free, lower toxicity |

| Environmental Impact | Harmful due to lead content | Environmentally friendly |

| Mechanical Strength | Good ductility and strength | Higher hardness, less ductile |

| Joint Reliability | Proven, reliable in electronics | Requires precise processing |

| Applications | Legacy electronics, repair | Modern electronics, RoHS compliant |

| Cost | Lower cost | Higher cost |

Introduction to Soldering Materials

Lead-tin solder, historically favored for its low melting point and excellent wetting properties, consists primarily of a tin-lead alloy with typical ratios like 60/40 or 63/37. Lead-free solder, increasingly used due to environmental regulations such as RoHS, typically combines tin with metals like silver, copper, and bismuth, offering higher melting points and improved mechanical strength. Understanding these material differences is essential for selecting the right solder in electronics manufacturing, balancing factors like thermal performance, joint reliability, and regulatory compliance.

Composition of Lead-Tin Solder

Lead-tin solder primarily consists of an alloy containing approximately 60% tin and 40% lead, though variations can range from 40% to 63% tin based on melting point requirements. The eutectic composition, commonly 63% tin and 37% lead, provides a low melting point of 183degC, ideal for reliable electrical connections. This alloy balances excellent wetting properties and mechanical strength, making it a preferred choice in traditional electronics assembly despite environmental concerns.

Overview of Lead-Free Solder

Lead-free solder primarily consists of a tin alloy combined with metals such as silver, copper, or bismuth, designed to meet environmental regulations like RoHS. It offers improved thermal fatigue resistance and reduced toxicity compared to traditional lead-tin solder. Despite a higher melting point and different mechanical properties, lead-free solder is increasingly preferred for electronic assembly due to enhanced sustainability and regulatory compliance.

Melting Points: Lead-Tin vs Lead-Free Solder

Lead-tin solder typically melts at a lower temperature range of around 183-190degC, providing reliable flow and strong joint formation in electronics. In contrast, lead-free solder, commonly composed of tin with silver, copper, and other metals, melts at higher temperatures ranging from 217-227degC. The higher melting point of lead-free solder requires adjusted soldering processes and can influence thermal stress on components during assembly.

Electrical and Mechanical Properties

Lead-tin solder offers superior electrical conductivity and ease of melting, facilitating effective circuit connections with low resistivity, while lead-free solder generally exhibits higher melting points and slightly increased electrical resistance. Mechanically, lead-tin solder provides excellent ductility and fatigue resistance, enabling reliable joint integrity under thermal cycling and mechanical stress, whereas lead-free alternatives tend to be harder and more brittle, raising the risk of joint cracking. The choice between lead-tin and lead-free solder significantly impacts long-term performance and durability in electronic assemblies, especially in high-reliability applications.

Health and Environmental Concerns

Lead-tin solder poses significant health risks due to lead's toxicity, causing neurological damage and developmental issues upon prolonged exposure. Lead-free solder, primarily composed of tin combined with silver or copper, mitigates these hazards but may introduce increased brittleness and higher melting points. Environmental concerns favor lead-free solder as it reduces soil and water contamination, aligning with Restriction of Hazardous Substances (RoHS) regulations aimed at minimizing lead pollution.

Regulatory Standards and Compliance

Lead-tin solder, traditionally used in electronics, faces increasing restrictions under regulatory standards such as RoHS (Restriction of Hazardous Substances), which limits lead content to protect human health and the environment. Lead-free solder, composed mainly of tin with silver and copper, complies with these regulations by eliminating hazardous lead, ensuring adherence to global environmental and safety guidelines. Manufacturers and industries prioritize lead-free solder to meet international compliance requirements and reduce toxic exposure in electronic waste management.

Cost Comparison: Lead-Tin vs Lead-Free

Lead-tin solder typically costs less than lead-free alternatives due to lower material and manufacturing expenses, making it a more budget-friendly choice for electronics assembly. Lead-free solder, often composed of tin, silver, and copper alloys, incurs higher costs because of pricier raw materials and stricter compliance with RoHS regulations. Companies must weigh the upfront cost savings of lead-tin solder against potential regulatory penalties and environmental considerations favoring lead-free options.

Applications in Electronics Manufacturing

Lead-tin solder remains a preferred choice in electronics manufacturing for its lower melting point and superior wetting properties, facilitating reliable connections on delicate components like printed circuit boards (PCBs). Lead-free solder, composed primarily of tin with silver and copper, is increasingly mandated due to environmental regulations such as RoHS, ensuring compliance while maintaining adequate mechanical strength for consumer electronics. High-reliability sectors such as aerospace and medical devices often still balance between both solders, optimizing performance and regulatory adherence based on specific application requirements.

Choosing the Right Solder for Your Project

Lead-tin solder offers excellent electrical conductivity and lower melting points, making it ideal for delicate electronic components, but its toxicity requires careful handling and disposal. Lead-free solder, often composed of tin, silver, and copper, provides a safer, environmentally friendly alternative with higher melting temperatures suited for RoHS-compliant projects. Selecting the right solder depends on factors like project safety requirements, component sensitivity, and regulatory standards to ensure both performance and compliance.

Lead-tin Solder vs Lead-free Solder Infographic

materialdif.com

materialdif.com