Matte tin offers a smooth, non-reflective finish that reduces glare and enhances the visibility of printed designs, making it ideal for premium packaging. Bright tin, on the other hand, has a shiny, reflective surface that provides a classic, eye-catching look commonly used in food and confectionery containers. Choosing between matte and bright tin depends on the desired aesthetic and brand presentation of the product.

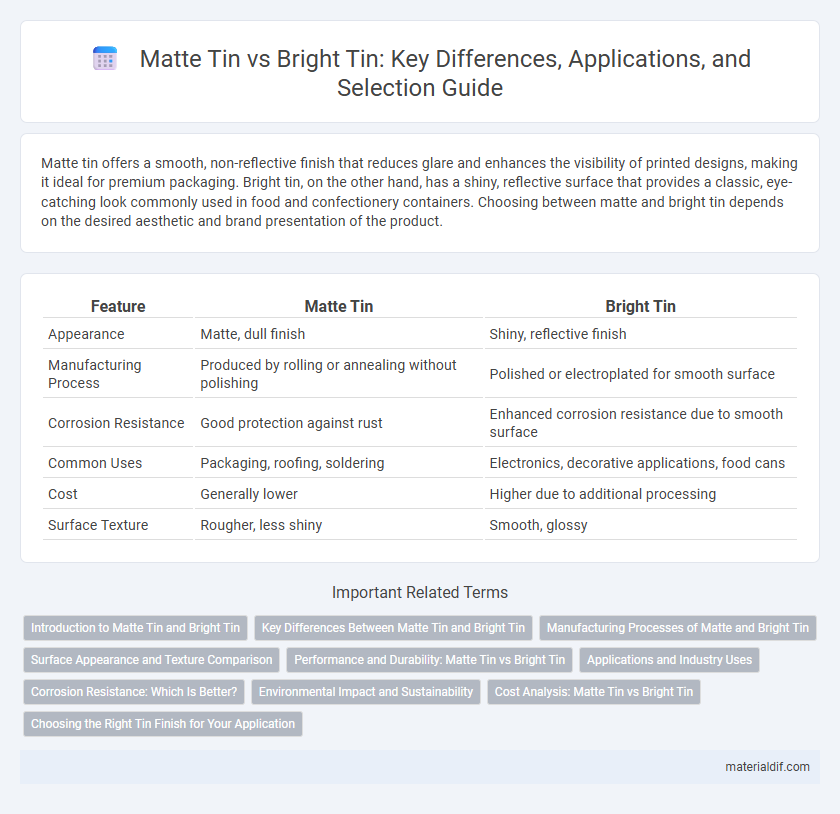

Table of Comparison

| Feature | Matte Tin | Bright Tin |

|---|---|---|

| Appearance | Matte, dull finish | Shiny, reflective finish |

| Manufacturing Process | Produced by rolling or annealing without polishing | Polished or electroplated for smooth surface |

| Corrosion Resistance | Good protection against rust | Enhanced corrosion resistance due to smooth surface |

| Common Uses | Packaging, roofing, soldering | Electronics, decorative applications, food cans |

| Cost | Generally lower | Higher due to additional processing |

| Surface Texture | Rougher, less shiny | Smooth, glossy |

Introduction to Matte Tin and Bright Tin

Matte tin features a dull, non-reflective surface commonly used for soldering and coating applications due to its excellent adhesion properties and resistance to oxidation. Bright tin, on the other hand, has a shiny, reflective finish achieved through electroplating, favored for its aesthetic appeal and enhanced corrosion resistance. Both types are crucial in electronics manufacturing, with matte tin preferred for functional layers and bright tin for decorative and protective coatings.

Key Differences Between Matte Tin and Bright Tin

Matte tin features a dull, non-reflective surface due to its oxidized finish, providing excellent solderability and corrosion resistance. Bright tin, in contrast, has a shiny, reflective surface achieved through electroplating, offering superior aesthetic appeal and conductivity. Key differences include the visual appearance, surface texture, and typical applications, with matte tin favored for functional coatings and bright tin preferred for decorative and electronic uses.

Manufacturing Processes of Matte and Bright Tin

Matte tin is produced through a process involving electroplating with a matte finish achieved by adding fine particles or using specific plating baths containing additives like alkyl sulfates that create a dull, non-reflective surface. Bright tin is created by electroplating with brighteners such as organic additives that refine the grain structure, resulting in a smooth, reflective, and shiny finish favored for its aesthetic and corrosion-resistant properties. The choice between matte and bright tin plating depends on desired surface characteristics and application requirements in electronics, packaging, and industrial uses.

Surface Appearance and Texture Comparison

Matte tin features a dull, non-reflective surface characterized by a rougher texture due to its coarse grain structure, making it ideal for applications requiring reduced glare and enhanced slip resistance. Bright tin displays a smooth, highly reflective surface with a fine grain texture achieved through electroplating or polishing processes, offering superior aesthetic appeal and corrosion resistance. The distinct surface appearances influence their suitability in various industries, with matte tin preferred for functional coatings and bright tin favored in decorative or packaging uses.

Performance and Durability: Matte Tin vs Bright Tin

Matte tin offers superior wear resistance and corrosion protection, making it ideal for applications requiring long-term durability under harsh conditions. Bright tin, characterized by its smooth and lustrous surface, provides excellent electrical conductivity and is preferred in electronic components where performance precision is critical. Choosing between matte and bright tin depends on balancing the need for robust surface protection against the requirement for optimum conductivity and aesthetic finish.

Applications and Industry Uses

Matte tin is widely used in soldering applications due to its superior solderability and reduced risk of tin whisker formation, especially in electronics and automotive industries where reliability is critical. Bright tin, prized for its smooth, reflective finish, is commonly applied in decorative plating for consumer goods and food packaging because of its corrosion resistance and aesthetic appeal. Both forms are essential in the tin plating industry, with matte tin preferred for functional coatings and bright tin favored for visual enhancement and protective layers.

Corrosion Resistance: Which Is Better?

Matte tin offers superior corrosion resistance compared to bright tin due to its thicker, more uniform coating that protects underlying metals effectively. Bright tin, while visually appealing with its shiny finish, tends to have a thinner layer, making it more susceptible to corrosion, especially in harsh environments. For applications requiring enhanced durability against oxidation and moisture, matte tin is the preferred choice.

Environmental Impact and Sustainability

Matte tin coatings typically have lower environmental impact due to their simpler production processes that consume less energy and generate fewer emissions compared to bright tin plating, which often involves hazardous chemicals and higher energy use. The sustainability of matte tin is enhanced by its reduced use of harmful substances and easier recyclability, whereas bright tin's glossy finish requires additional treatments that can produce toxic waste. Prioritizing matte tin in industrial applications supports eco-friendly practices by minimizing ecological footprint and promoting safer manufacturing environments.

Cost Analysis: Matte Tin vs Bright Tin

Matte tin typically incurs lower production and finishing costs due to its simpler manufacturing process and less stringent surface quality requirements, making it a cost-effective option for bulk industrial applications. Bright tin demands higher expenses because of the additional polishing, plating, and quality control processes needed to achieve its reflective, smooth surface, often increasing both material and labor costs. When selecting between matte and bright tin, manufacturers must balance these cost differences against the desired aesthetic and functional properties to optimize overall production expenses.

Choosing the Right Tin Finish for Your Application

Matte tin offers a non-reflective, smooth surface ideal for applications requiring reduced glare and a subtle aesthetic, while bright tin provides a shiny, reflective finish that enhances visual appeal and corrosion resistance. Selecting the right tin finish depends on factors such as the environmental conditions, desired appearance, and specific functional requirements of the product. Matte tin is preferred in industrial and electronic components for its anti-glare properties, whereas bright tin suits decorative and food packaging applications due to its attractive sheen and hygiene benefits.

Matte tin vs bright tin Infographic

materialdif.com

materialdif.com