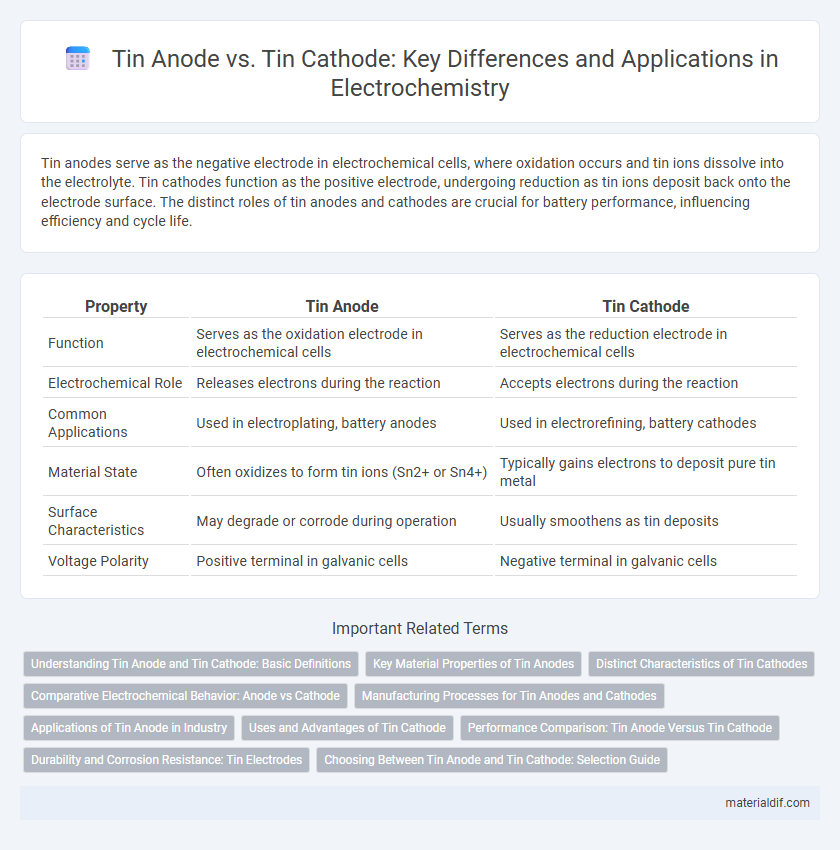

Tin anodes serve as the negative electrode in electrochemical cells, where oxidation occurs and tin ions dissolve into the electrolyte. Tin cathodes function as the positive electrode, undergoing reduction as tin ions deposit back onto the electrode surface. The distinct roles of tin anodes and cathodes are crucial for battery performance, influencing efficiency and cycle life.

Table of Comparison

| Property | Tin Anode | Tin Cathode |

|---|---|---|

| Function | Serves as the oxidation electrode in electrochemical cells | Serves as the reduction electrode in electrochemical cells |

| Electrochemical Role | Releases electrons during the reaction | Accepts electrons during the reaction |

| Common Applications | Used in electroplating, battery anodes | Used in electrorefining, battery cathodes |

| Material State | Often oxidizes to form tin ions (Sn2+ or Sn4+) | Typically gains electrons to deposit pure tin metal |

| Surface Characteristics | May degrade or corrode during operation | Usually smoothens as tin deposits |

| Voltage Polarity | Positive terminal in galvanic cells | Negative terminal in galvanic cells |

Understanding Tin Anode and Tin Cathode: Basic Definitions

Tin anode refers to the electrode where oxidation occurs in an electrochemical cell, releasing electrons as tin atoms lose electrons and enter the electrolyte. Tin cathode is the electrode where reduction takes place, gaining electrons as tin ions from the electrolyte are deposited as solid tin. Understanding these basic definitions helps clarify the role of tin electrodes in processes like electroplating, rechargeable batteries, and corrosion protection.

Key Material Properties of Tin Anodes

Tin anodes exhibit excellent electrochemical stability and high conductivity, enhancing their performance in rechargeable batteries and electroplating applications. Their low corrosion rate and strong resistance to oxidation ensure prolonged operational life and improved efficiency. The ductility and malleability of tin anodes facilitate easy fabrication into various shapes, optimizing their integration into energy storage systems.

Distinct Characteristics of Tin Cathodes

Tin cathodes exhibit higher electrochemical stability and enhanced corrosion resistance compared to tin anodes, making them preferable for long-term applications in electroplating and battery technology. Their distinct crystalline structure promotes efficient electron transfer, resulting in improved current efficiency and uniform deposition. These properties contribute to reduced maintenance needs and superior performance in electrochemical cells.

Comparative Electrochemical Behavior: Anode vs Cathode

Tin anodes exhibit higher oxidation susceptibility, promoting efficient electron release during electrochemical reactions, whereas tin cathodes demonstrate superior reduction capabilities by facilitating electron acceptance with minimal polarization. The electrochemical behavior of tin anodes is characterized by their ability to undergo anodic dissolution, forming stable tin oxide films that influence corrosion resistance and current efficiency. Conversely, tin cathodes favor hydrogen evolution reactions in aqueous electrolytes, impacting their overall electrochemical stability and conductivity in battery applications.

Manufacturing Processes for Tin Anodes and Cathodes

Tin anodes are manufactured through electrodeposition, where pure tin is deposited onto a conductive substrate under controlled current density and temperature to ensure uniform thickness and crystalline structure. Tin cathodes are produced via electrorefining, involving the reduction of tin ions onto a cathode surface, resulting in high-purity tin with minimal impurities. Both processes require precise control of electrolyte composition and operational parameters to optimize the quality and performance of the tin electrodes in industrial applications.

Applications of Tin Anode in Industry

Tin anodes are extensively used in electroplating industries to provide a uniform and corrosion-resistant coating on metal surfaces, enhancing durability and conductivity. In electronics manufacturing, tin anodes facilitate the deposition of tin layers essential for soldering and circuit protection. Industrial applications also leverage tin anodes in chemical processing for efficient electrolysis and refining processes.

Uses and Advantages of Tin Cathode

Tin cathodes are primarily used in the electroplating industry to produce a smooth, corrosion-resistant coating on metal surfaces, enhancing durability and electrical conductivity. Their advantages include high purity levels, consistent deposition rates, and improved energy efficiency compared to tin anodes, which often suffer from uneven wear and contamination. The stable performance of tin cathodes makes them essential in manufacturing electronics, soldering materials, and corrosion-resistant coatings.

Performance Comparison: Tin Anode Versus Tin Cathode

Tin anodes exhibit higher electrochemical activity and faster ion exchange rates compared to tin cathodes, leading to improved charge efficiency and reduced polarization during battery cycling. The tin cathode typically demonstrates greater structural stability and lower volume expansion, contributing to enhanced cycle life and mechanical integrity. Performance optimization depends on balancing the high capacity and reactivity of tin anodes with the durability and stability characteristics of tin cathodes in energy storage applications.

Durability and Corrosion Resistance: Tin Electrodes

Tin anodes exhibit superior corrosion resistance compared to tin cathodes, making them more durable in electrochemical applications such as plating and energy storage. The passive oxide layer formed on tin anodes protects the metal from aggressive environments, enhancing lifespan and maintaining conductivity. Conversely, tin cathodes are more prone to surface degradation under prolonged electrochemical stress, reducing their overall durability.

Choosing Between Tin Anode and Tin Cathode: Selection Guide

Selecting between tin anode and tin cathode depends on the specific electrochemical application and desired performance characteristics. Tin anodes are preferred in processes requiring efficient oxidation, such as in electroplating and battery applications, offering high electrochemical stability and consistent current distribution. Tin cathodes, on the other hand, provide superior reduction reactions and corrosion resistance, making them ideal for applications like electrolytic refining and protective coatings.

Tin Anode vs Tin Cathode Infographic

materialdif.com

materialdif.com