Drawn and ironed cans are manufactured from a single sheet of metal, offering a seamless structure that enhances durability and reduces the risk of leaks, making them ideal for preserving the freshness of tin pet food. In contrast, three-piece cans consist of a cylindrical body and two separate ends, which are seamed together, providing more flexibility in size and shape customization but potentially increasing susceptibility to corrosion at the seams. The choice between drawn and ironed cans versus three-piece cans depends on the balance between packaging integrity and design versatility required for tin pet products.

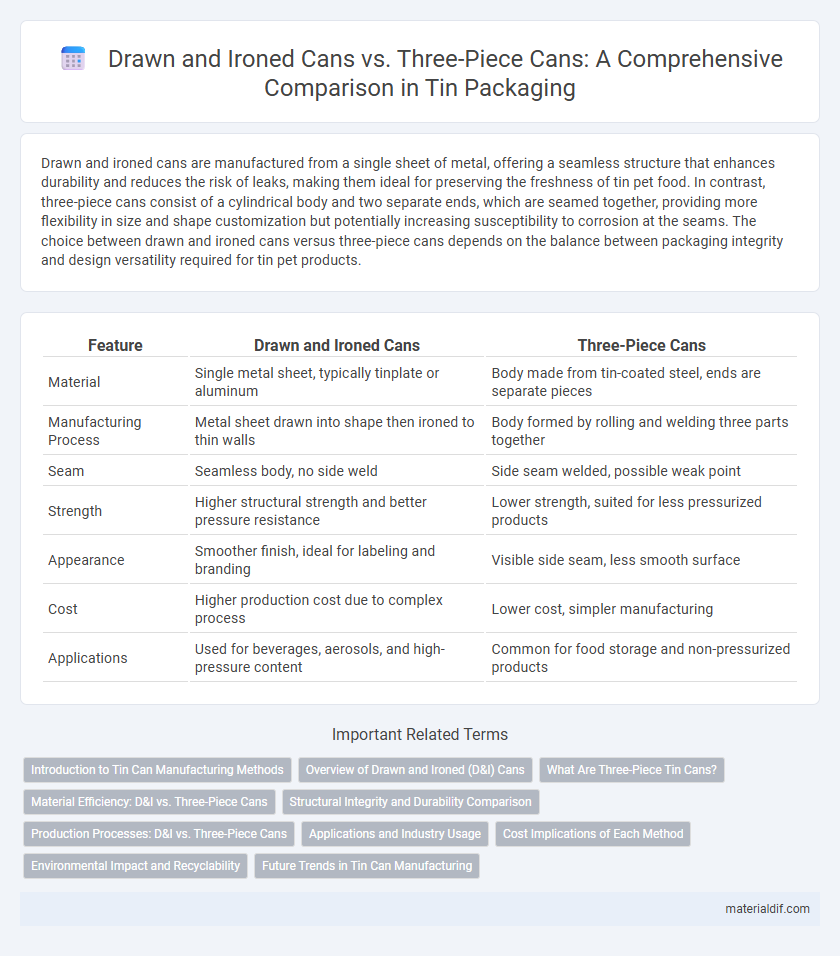

Table of Comparison

| Feature | Drawn and Ironed Cans | Three-Piece Cans |

|---|---|---|

| Material | Single metal sheet, typically tinplate or aluminum | Body made from tin-coated steel, ends are separate pieces |

| Manufacturing Process | Metal sheet drawn into shape then ironed to thin walls | Body formed by rolling and welding three parts together |

| Seam | Seamless body, no side weld | Side seam welded, possible weak point |

| Strength | Higher structural strength and better pressure resistance | Lower strength, suited for less pressurized products |

| Appearance | Smoother finish, ideal for labeling and branding | Visible side seam, less smooth surface |

| Cost | Higher production cost due to complex process | Lower cost, simpler manufacturing |

| Applications | Used for beverages, aerosols, and high-pressure content | Common for food storage and non-pressurized products |

Introduction to Tin Can Manufacturing Methods

Drawn and ironed cans are produced by shaping a single metal blank into a seamless, lightweight container, offering superior strength and an improved surface finish compared to three-piece cans. Three-piece cans consist of a cylindrical body made from a flat metal sheet welded or soldered to form the sides, combined with separate top and bottom pieces, making them versatile for larger packaging applications. The manufacturing choice between drawn and ironed versus three-piece cans depends on factors such as production speed, cost efficiency, and product requirements for durability and appearance.

Overview of Drawn and Ironed (D&I) Cans

Drawn and Ironed (D&I) cans are fabricated from a single tin-plated steel or aluminum sheet, offering superior strength and lightweight properties compared to three-piece cans. These cans feature a seamless body formed through deep drawing and ironing processes, reducing contamination risks and enhancing shelf appeal. Their uniform structure improves product preservation and is commonly used for beverages and aerosol containers due to superior mechanical integrity.

What Are Three-Piece Tin Cans?

Three-piece tin cans consist of a cylindrical body made from a tin-coated steel sheet, joined by a side seam, with separate tin-plated steel ends attached to the top and bottom. These cans provide excellent airtight sealing and are widely used for packaging food, beverages, and industrial products, leveraging the corrosion resistance of the tin coating. Compared to drawn and ironed cans, three-piece cans offer greater flexibility in shape and size but may have a higher risk of leakage at the seams if not properly manufactured.

Material Efficiency: D&I vs. Three-Piece Cans

Drawn and ironed (D&I) cans use a single metal sheet formed through deep drawing and ironing, minimizing welds and reducing material waste compared to three-piece cans composed of a cylindrical body and two separate ends. The seamless construction of D&I cans enhances structural integrity while requiring less tinplate material, contributing to better material efficiency and sustainability. In contrast, three-piece cans involve additional tin usage for welding seams and overlapping edges, often resulting in higher scrap rates and lower overall material efficiency.

Structural Integrity and Durability Comparison

Drawn and ironed (D&I) cans exhibit superior structural integrity due to their seamless body formed from a single sheet of tin-coated steel, reducing the risk of leaks and corrosion compared to three-piece cans that rely on welded seams. The absence of side seams in D&I cans enhances durability under high pressure and mechanical stress, making them ideal for carbonated beverages. Conversely, three-piece cans, constructed from separate body, bottom, and lid components, may be more prone to seam failure and require additional coatings to prevent corrosion, affecting their longevity.

Production Processes: D&I vs. Three-Piece Cans

Drawn and ironed (D&I) cans are produced by forming a single metal sheet into a seamless cylindrical shape through deep drawing and ironing, enhancing strength and reducing material usage. In contrast, three-piece cans consist of a cylindrical body formed by welding or soldering a metal sheet with separate top and bottom pieces, resulting in more complex assembly and higher chances of leakage. The D&I process offers greater efficiency in mass production with improved structural integrity compared to the multi-step fabrication of three-piece cans.

Applications and Industry Usage

Drawn and ironed cans dominate the beverage industry due to their seamless structure and superior strength, ideal for carbonated drinks requiring high pressure resistance. Three-piece cans are preferred in food packaging for their versatility and ease of customization, accommodating coatings and labels tailored to diverse products. Both types utilize tin coatings to prevent corrosion and ensure product safety across varying industry applications.

Cost Implications of Each Method

Drawn and ironed cans typically have higher production costs due to the complex deep-drawing and ironing processes requiring specialized machinery and increased energy consumption. Three-piece cans are generally more cost-effective for large production volumes because of simpler manufacturing steps involving stamping, forming, and welding separate components. Material waste is lower in drawn and ironed cans, which can offset initial expenses, while three-piece cans may incur higher costs in sealing and potential leakage prevention.

Environmental Impact and Recyclability

Drawn and ironed (D&I) cans, made from a single sheet of tin-coated steel, offer superior recyclability due to their seamless structure, reducing contamination during recycling processes. Three-piece cans consist of a tin-coated steel body welded with separate tinplate lids and bottoms, which can generate more waste and are harder to recycle efficiently because of their multi-material construction. The environmental impact of D&I cans is lower, as they require less energy for production and result in fewer emissions compared to the more resource-intensive manufacturing of three-piece cans.

Future Trends in Tin Can Manufacturing

Drawn and ironed cans offer superior strength and a seamless design, catering to future demands for lightweight and durable packaging in the tin can industry. Three-piece cans maintain cost-efficiency and versatility, with ongoing innovations aimed at improving weld quality and reducing material usage. Emerging trends emphasize sustainable materials and advanced coating technologies to enhance recyclability and extend product shelf life.

Drawn and ironed cans vs Three-piece cans Infographic

materialdif.com

materialdif.com