Tin-coated steel offers superior corrosion resistance and a smoother surface finish compared to galvanized steel, making it ideal for food packaging and decorative applications. While galvanized steel is coated with zinc to provide durability and rust protection, tin coating creates a more uniform barrier, preventing contamination and extending product shelf life. Tin-coated steel also allows for better solderability, enhancing its use in electrical components and cans.

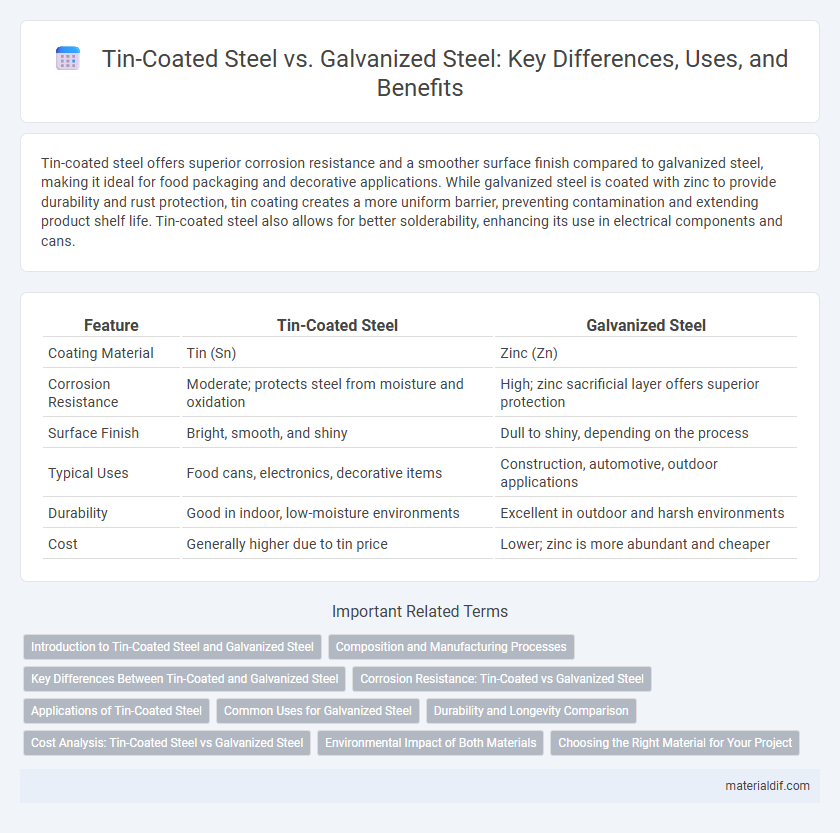

Table of Comparison

| Feature | Tin-Coated Steel | Galvanized Steel |

|---|---|---|

| Coating Material | Tin (Sn) | Zinc (Zn) |

| Corrosion Resistance | Moderate; protects steel from moisture and oxidation | High; zinc sacrificial layer offers superior protection |

| Surface Finish | Bright, smooth, and shiny | Dull to shiny, depending on the process |

| Typical Uses | Food cans, electronics, decorative items | Construction, automotive, outdoor applications |

| Durability | Good in indoor, low-moisture environments | Excellent in outdoor and harsh environments |

| Cost | Generally higher due to tin price | Lower; zinc is more abundant and cheaper |

Introduction to Tin-Coated Steel and Galvanized Steel

Tin-coated steel is created by electroplating a thin layer of tin onto the surface of steel, offering excellent corrosion resistance and a smooth, non-toxic finish ideal for food packaging and preservation. Galvanized steel is produced by hot-dip coating steel with a layer of zinc, providing robust protection against rust and corrosion in construction and outdoor applications. Both materials enhance the durability of steel but differ significantly in coating composition and targeted use cases.

Composition and Manufacturing Processes

Tin-coated steel consists of a thin layer of tin electroplated onto a cold-rolled steel substrate, providing corrosion resistance and a smooth surface for soldering or painting. Galvanized steel is produced by hot-dip immersing steel in molten zinc, creating a robust zinc-iron alloy layer that offers superior rust protection. The manufacturing process differences impact the coating adhesion, durability, and application suitability of these steels in packaging, automotive, and construction industries.

Key Differences Between Tin-Coated and Galvanized Steel

Tin-coated steel features a thin layer of tin applied to protect against corrosion and improve solderability, while galvanized steel is coated with a thicker layer of zinc offering superior rust resistance and durability. Tin coatings provide excellent electrical conductivity and a smooth surface ideal for food packaging, whereas galvanized steel's rugged zinc layer excels in outdoor and structural applications. The differing metal coatings significantly affect corrosion protection, cost, and suitability for various industrial uses.

Corrosion Resistance: Tin-Coated vs Galvanized Steel

Tin-coated steel offers superior corrosion resistance in acidic and food-related environments due to tin's inert and non-toxic properties, making it ideal for packaging and food containers. Galvanized steel, coated with a layer of zinc, provides robust protection against rust in outdoor and industrial applications by forming a protective oxide layer that inhibits corrosion. While galvanized steel excels in heavy-duty protection and abrasion resistance, tin-coated steel is preferred for applications requiring a clean, non-reactive surface and enhanced resistance to mild corrosion.

Applications of Tin-Coated Steel

Tin-coated steel is widely used in food packaging, especially for cans that require corrosion resistance and non-toxic surfaces to preserve food quality. Its application extends to automotive and electrical components, where its superior solderability and corrosion protection enhance durability and performance. Compared to galvanized steel, tin-coated steel is preferred in environments demanding high corrosion resistance without compromising aesthetic appeal.

Common Uses for Galvanized Steel

Galvanized steel is widely used in construction for roofing, wall panels, and structural framing due to its superior corrosion resistance from zinc coating. It is also common in automotive parts, outdoor furniture, and HVAC systems where durability against weathering is essential. The protective zinc layer extends the lifespan of steel by preventing rust, making galvanized steel ideal for outdoor and industrial applications.

Durability and Longevity Comparison

Tin-coated steel offers superior corrosion resistance in mildly acidic and food-related environments, extending the longevity of packaging and automotive components. Galvanized steel, coated with zinc, provides robust protection against rust and is ideal for outdoor and industrial applications exposed to harsher elements. The durability of galvanized steel typically outperforms tin-coated steel in long-term exposure to moisture and weather, making it more suitable for construction and infrastructure uses.

Cost Analysis: Tin-Coated Steel vs Galvanized Steel

Tin-coated steel generally incurs higher material and processing costs compared to galvanized steel due to the use of tin plating, which provides superior corrosion resistance and a more aesthetically pleasing finish. Galvanized steel offers a more cost-effective solution with zinc coating, making it suitable for large-scale industrial applications where budget constraints are critical. The choice between tin-coated and galvanized steel often hinges on balancing the higher upfront costs of tin plating against the long-term durability and corrosion protection benefits it provides.

Environmental Impact of Both Materials

Tin-coated steel offers superior corrosion resistance with a thinner metal layer, resulting in less material usage and lower energy consumption during production. Galvanized steel production involves zinc mining and more intensive energy use, contributing to higher carbon emissions and potential heavy metal runoff. Recycling rates are high for both materials, but tin-coated steel's smaller environmental footprint makes it a more sustainable choice for reducing ecological impact.

Choosing the Right Material for Your Project

Tin-coated steel offers superior corrosion resistance and a smooth, non-porous surface ideal for food packaging and electronics, ensuring extended durability. Galvanized steel, coated with zinc, provides excellent rust protection and cost-effectiveness, making it suitable for outdoor construction and automotive applications. Selecting the right material depends on project-specific requirements such as environmental exposure, budget constraints, and desired lifespan.

Tin-Coated Steel vs Galvanized Steel Infographic

materialdif.com

materialdif.com