Pure tin offers superior corrosion resistance and excellent electrical conductivity, making it ideal for high-performance applications. Recycled tin, while more environmentally sustainable and cost-effective, may contain impurities that can affect its quality and reliability. Choosing between pure and recycled tin requires balancing performance needs with environmental and economic considerations.

Table of Comparison

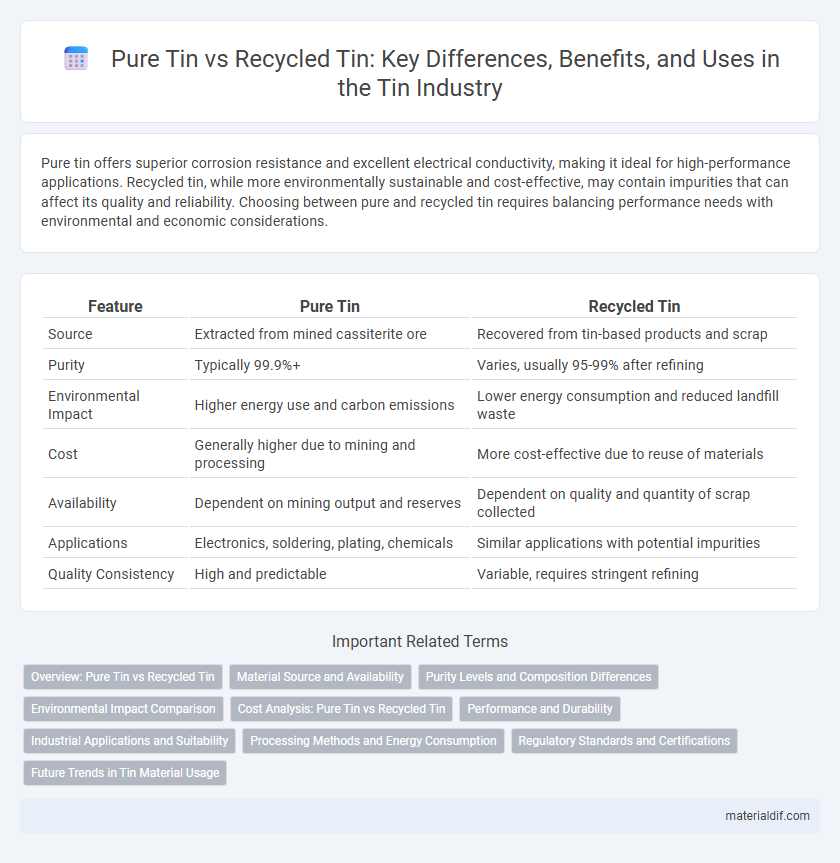

| Feature | Pure Tin | Recycled Tin |

|---|---|---|

| Source | Extracted from mined cassiterite ore | Recovered from tin-based products and scrap |

| Purity | Typically 99.9%+ | Varies, usually 95-99% after refining |

| Environmental Impact | Higher energy use and carbon emissions | Lower energy consumption and reduced landfill waste |

| Cost | Generally higher due to mining and processing | More cost-effective due to reuse of materials |

| Availability | Dependent on mining output and reserves | Dependent on quality and quantity of scrap collected |

| Applications | Electronics, soldering, plating, chemicals | Similar applications with potential impurities |

| Quality Consistency | High and predictable | Variable, requires stringent refining |

Overview: Pure Tin vs Recycled Tin

Pure tin offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance electronic components. Recycled tin provides an eco-friendly alternative by reducing mining waste and conserving natural resources, though it may contain impurities that affect quality. Choosing between pure and recycled tin depends on a balance between performance requirements and environmental impact.

Material Source and Availability

Pure tin is extracted primarily from cassiterite ore, making it a finite resource with geographically concentrated deposits, mainly in countries like China, Indonesia, and Peru. Recycled tin is sourced from scrap materials such as electronic waste and tin-plated steel, providing a sustainable alternative that reduces dependence on mined ore. Availability of recycled tin depends on efficient collection and processing systems, which can help stabilize supply amid fluctuating mining outputs.

Purity Levels and Composition Differences

Pure tin typically contains a purity level of 99.9% or higher, making it ideal for applications requiring minimal impurities and consistent material properties. Recycled tin often has a lower purity, averaging around 95-98%, due to the presence of alloying elements and contaminants introduced during previous usage. These compositional differences affect melting points, mechanical strength, and suitability for sensitive electronics or soldering applications.

Environmental Impact Comparison

Pure tin mining requires extensive energy consumption and generates significant habitat disruption, contributing to higher carbon emissions and ecological degradation. Recycled tin drastically reduces environmental footprint by lowering energy use by up to 60%, minimizing mining waste, and curbing greenhouse gas emissions. Utilizing recycled tin supports resource conservation and aligns with circular economy principles, promoting sustainable metal usage.

Cost Analysis: Pure Tin vs Recycled Tin

Pure tin typically incurs higher production costs due to mining, refining, and energy-intensive processes, whereas recycled tin benefits from reduced raw material expenses and lower energy consumption. The price advantage of recycled tin can fluctuate based on the availability of scrap materials and the efficiency of recycling technologies. Cost analysis reveals that recycling tin not only lowers manufacturing expenses but also minimizes environmental impact, promoting sustainable supply chain economics.

Performance and Durability

Pure tin offers superior electrical conductivity and corrosion resistance compared to recycled tin, making it ideal for high-performance electronic applications. Recycled tin may contain trace impurities that can slightly reduce solderability and mechanical strength, affecting long-term durability. However, advances in refining processes have significantly minimized performance gaps, allowing recycled tin to meet most industrial durability standards.

Industrial Applications and Suitability

Pure tin offers superior conductivity and corrosion resistance, making it ideal for high-performance electronic components and soldering applications. Recycled tin, while slightly lower in purity, provides a cost-effective and environmentally sustainable option for manufacturing coatings, alloys, and packaging materials. Industrial applications prioritize pure tin for precision and durability, whereas recycled tin suits bulk production requiring balanced performance and eco-conscious sourcing.

Processing Methods and Energy Consumption

Pure tin typically undergoes electrolysis or zone refining, which demands high energy input due to the need for precise temperature control and purity maintenance. Recycled tin involves melting down scrap tin with fluxes to remove impurities, a process that consumes significantly less energy compared to producing pure tin from ore. Energy consumption in recycled tin processing is estimated to be up to 60% lower, contributing to reduced environmental impact and cost efficiency.

Regulatory Standards and Certifications

Pure tin complies with stringent regulatory standards such as ASTM B545 and IPC-4556, ensuring high purity levels and consistent performance in electronic applications. Recycled tin, to meet certifications like RoHS and REACH, undergoes rigorous testing for contaminants and heavy metals to maintain safety and environmental compliance. Both forms require adherence to ISO 9001 quality management systems, but recycled tin emphasizes traceability and responsible sourcing to align with sustainability regulations.

Future Trends in Tin Material Usage

Future trends in tin material usage emphasize increased adoption of recycled tin due to its lower environmental impact and cost efficiency. Advances in recycling technology are improving the purity and quality of recycled tin, making it comparable to pure tin for electronics and solder applications. Industry projections indicate a significant rise in demand for sustainable tin sources as global regulations tighten and green manufacturing initiatives expand.

Pure tin vs Recycled tin Infographic

materialdif.com

materialdif.com