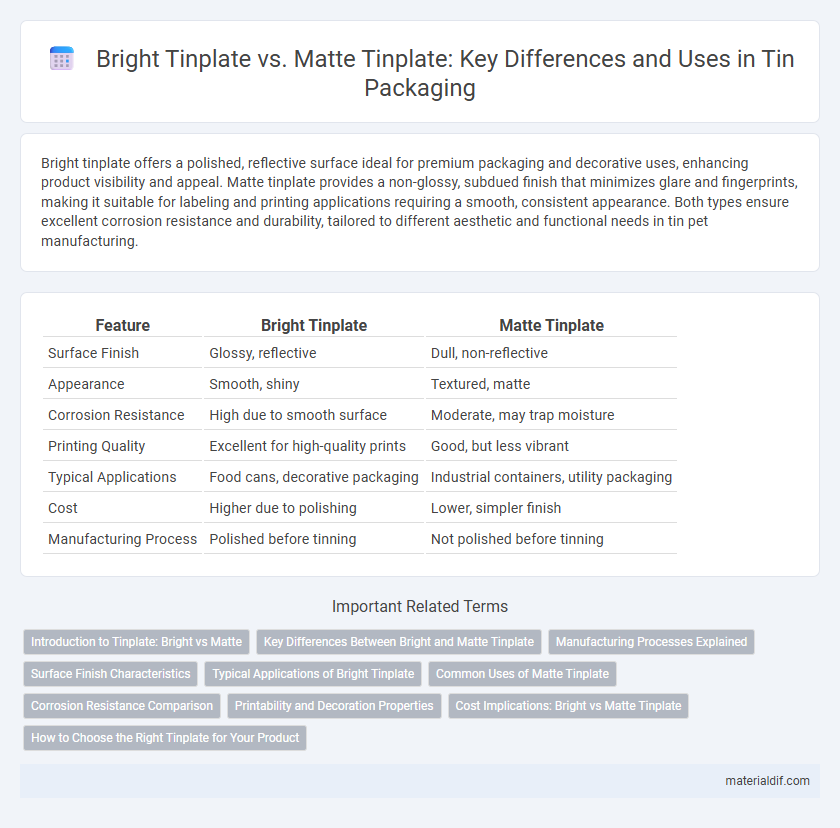

Bright tinplate offers a polished, reflective surface ideal for premium packaging and decorative uses, enhancing product visibility and appeal. Matte tinplate provides a non-glossy, subdued finish that minimizes glare and fingerprints, making it suitable for labeling and printing applications requiring a smooth, consistent appearance. Both types ensure excellent corrosion resistance and durability, tailored to different aesthetic and functional needs in tin pet manufacturing.

Table of Comparison

| Feature | Bright Tinplate | Matte Tinplate |

|---|---|---|

| Surface Finish | Glossy, reflective | Dull, non-reflective |

| Appearance | Smooth, shiny | Textured, matte |

| Corrosion Resistance | High due to smooth surface | Moderate, may trap moisture |

| Printing Quality | Excellent for high-quality prints | Good, but less vibrant |

| Typical Applications | Food cans, decorative packaging | Industrial containers, utility packaging |

| Cost | Higher due to polishing | Lower, simpler finish |

| Manufacturing Process | Polished before tinning | Not polished before tinning |

Introduction to Tinplate: Bright vs Matte

Bright tinplate features a smooth, reflective surface achieved through final polishing, offering superior corrosion resistance and an attractive finish ideal for consumer packaging. Matte tinplate has a dull, non-reflective surface created by a matte finish process, providing better paint adhesion and reduced glare, commonly used in industrial and decorative applications. Both types consist of a thin tin coating over steel, but their surface treatments influence their suitability for different uses in food, beverage, and chemical packaging.

Key Differences Between Bright and Matte Tinplate

Bright tinplate features a polished, reflective surface achieved through a smoothing process, resulting in superior corrosion resistance and high visual appeal, ideal for premium packaging applications. Matte tinplate has a dull, non-reflective finish created by texturing the steel surface before tin coating, offering better printability and reduced glare, making it preferred for labeling and decorative uses. Key differences include surface appearance, corrosion resistance, and suitability for printing, with bright tinplate optimized for aesthetic presentation and matte tinplate designed for functional print performance.

Manufacturing Processes Explained

Bright tinplate is produced through electroplating with a polished steel strip, resulting in a smooth and reflective surface achieved by using finely controlled electrolytic conditions and post-treatment polishing. Matte tinplate involves similar electroplating but uses a matte-finish steel base or matte chemical treatments to create a duller, non-reflective surface. The manufacturing process variations, including steel substrate preparation and electrolytic bath composition, are critical in determining the final surface characteristics essential for packaging and industrial applications.

Surface Finish Characteristics

Bright tinplate features a highly reflective, smooth surface finish that enhances visual appeal and corrosion resistance, making it ideal for premium packaging. Matte tinplate provides a non-glossy, textured surface that minimizes glare and hides fingerprints, suitable for practical applications requiring discretion. Both finishes influence paint adherence and printing quality, with bright tinplate offering superior clarity and matte tinplate supporting better ink adhesion.

Typical Applications of Bright Tinplate

Bright tinplate is predominantly used in packaging applications demanding high visual appeal and product visibility, such as food and beverage cans, confectionery, and pharmaceutical containers. Its reflective surface enhances printed graphics and branding, making it ideal for products requiring premium presentation and shelf impact. The corrosion resistance and ease of weldability further support its widespread use in decorative and protective packaging solutions.

Common Uses of Matte Tinplate

Matte tinplate is commonly used in packaging applications where a non-reflective surface is preferred, such as food cans, paint cans, and aerosol containers. Its low-gloss finish helps reduce glare and enhances label readability, making it ideal for consumer goods that require clear branding and product information. The corrosion resistance and durability of matte tinplate also make it suitable for industrial packaging and household products.

Corrosion Resistance Comparison

Bright tinplate offers superior corrosion resistance due to its smooth, reflective surface that minimizes moisture and contaminant adherence, thereby protecting the underlying steel effectively. Matte tinplate, with its dull and rough surface, tends to retain more moisture and impurities, leading to increased susceptibility to corrosion over time. Studies indicate bright tinplate's protective coating extends the lifespan of tin cans and containers by reducing oxidation rates compared to matte tinplate variants.

Printability and Decoration Properties

Bright tinplate offers superior printability due to its smooth, reflective surface which allows for high-quality, detailed decoration and vibrant color reproduction. Matte tinplate, with its duller finish, provides a more muted print effect but enhances ink adhesion and reduces glare, making it suitable for designs requiring a subtle, sophisticated look. Both materials are widely used in packaging, with bright tinplate favored for premium, eye-catching products and matte tinplate preferred for elegant, understated presentation.

Cost Implications: Bright vs Matte Tinplate

Bright tinplate typically incurs higher costs due to its polished surface finish and additional processing steps, making it ideal for premium packaging requiring superior aesthetic appeal. Matte tinplate is more cost-effective, as it undergoes less surface treatment and provides a functional, non-reflective finish suited for budget-conscious packaging solutions. Selecting between bright and matte tinplate directly impacts production expenses, influencing overall project budgeting and product positioning in the market.

How to Choose the Right Tinplate for Your Product

Selecting the right tinplate for your product depends on factors such as desired appearance, corrosion resistance, and printing quality. Bright tinplate offers a glossy, reflective finish ideal for premium packaging and high-quality printing, while matte tinplate provides a subdued, non-reflective surface suited for products requiring a rustic or understated look. Consider product aesthetics, branding requirements, and environmental exposure when choosing between bright and matte tinplate.

Bright Tinplate vs Matte Tinplate Infographic

materialdif.com

materialdif.com