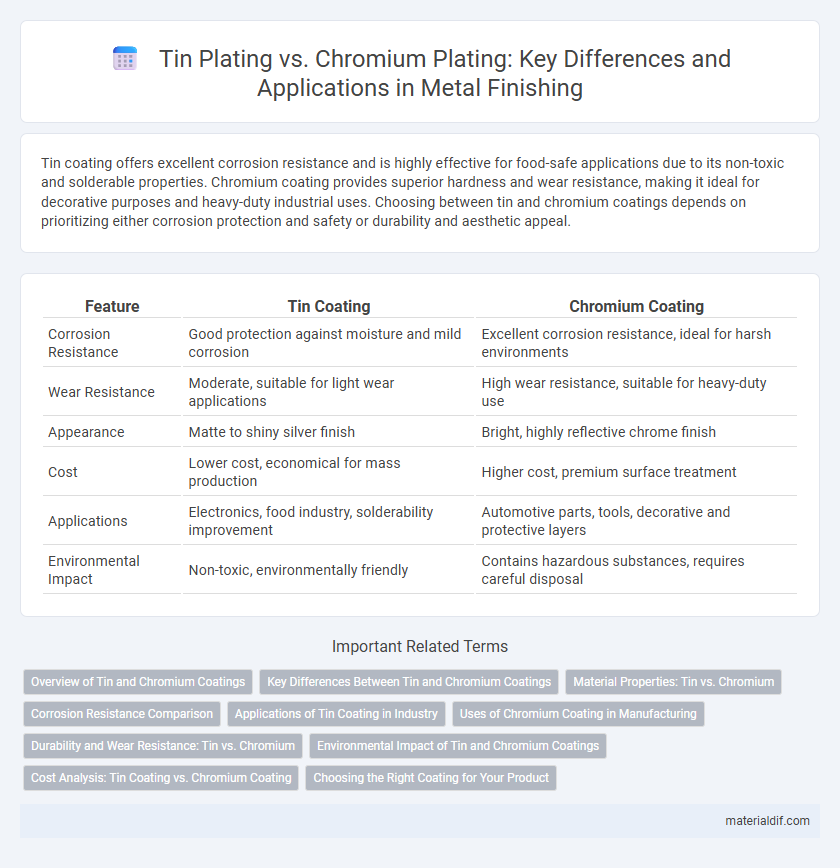

Tin coating offers excellent corrosion resistance and is highly effective for food-safe applications due to its non-toxic and solderable properties. Chromium coating provides superior hardness and wear resistance, making it ideal for decorative purposes and heavy-duty industrial uses. Choosing between tin and chromium coatings depends on prioritizing either corrosion protection and safety or durability and aesthetic appeal.

Table of Comparison

| Feature | Tin Coating | Chromium Coating |

|---|---|---|

| Corrosion Resistance | Good protection against moisture and mild corrosion | Excellent corrosion resistance, ideal for harsh environments |

| Wear Resistance | Moderate, suitable for light wear applications | High wear resistance, suitable for heavy-duty use |

| Appearance | Matte to shiny silver finish | Bright, highly reflective chrome finish |

| Cost | Lower cost, economical for mass production | Higher cost, premium surface treatment |

| Applications | Electronics, food industry, solderability improvement | Automotive parts, tools, decorative and protective layers |

| Environmental Impact | Non-toxic, environmentally friendly | Contains hazardous substances, requires careful disposal |

Overview of Tin and Chromium Coatings

Tin coating offers excellent corrosion resistance and solderability, making it ideal for electronic components and food packaging applications. Chromium coating provides superior hardness and wear resistance, commonly used to enhance durability in automotive and industrial parts. Both coatings serve protective functions but differ significantly in application-specific benefits and environmental impact.

Key Differences Between Tin and Chromium Coatings

Tin coating provides excellent corrosion resistance and solderability, making it ideal for applications in electronics and food packaging, while chromium coating offers superior hardness and wear resistance suited for automotive and industrial tools. Tin coatings are typically softer and more ductile, enhancing conductivity and ease of processing, whereas chromium coatings form a hard, abrasive-resistant surface that significantly extends component lifespan. Furthermore, tin is non-toxic and environmentally friendly, contrasting with chromium coatings which may involve hazardous hexavalent chromium compounds requiring careful handling.

Material Properties: Tin vs. Chromium

Tin coating offers excellent corrosion resistance and solderability due to its low melting point and non-toxic nature, making it ideal for electrical and food industry applications. Chromium coating provides superior hardness, wear resistance, and high-temperature stability, favored in automotive and aerospace components subjected to harsh conditions. Both materials exhibit distinct advantages: tin excels in chemical resistance and ease of processing, while chromium delivers enhanced mechanical durability and oxidation resistance.

Corrosion Resistance Comparison

Tin coating offers excellent corrosion resistance, particularly against moisture and mild acids, making it ideal for food containers and electronics. Chromium coating provides superior protection in harsh environments, resisting oxidation and wear due to its dense, hard surface and chemical inertness. For applications requiring long-term durability in aggressive conditions, chromium outperforms tin in corrosion resistance.

Applications of Tin Coating in Industry

Tin coating is widely used in the food and beverage industry for corrosion resistance and non-toxicity, making it ideal for tinplate cans and packaging. It also plays a critical role in the electronics sector by providing excellent solderability and electrical conductivity for circuit board components. Furthermore, tin coating is favored in automotive and plumbing industries to prevent rust and enhance the durability of steel parts.

Uses of Chromium Coating in Manufacturing

Chromium coating is widely used in manufacturing for its exceptional hardness, corrosion resistance, and aesthetic appeal, making it ideal for automotive parts, aerospace components, and decorative finishes. Unlike tin coating, chromium provides superior wear resistance and high-temperature stability, enhancing the durability of machine tools and molds. Its ability to create a smooth, reflective surface also supports applications in electronics and consumer goods where precision and appearance are critical.

Durability and Wear Resistance: Tin vs. Chromium

Tin coating offers moderate durability and corrosion resistance, making it suitable for applications requiring protection against moisture and mild wear. Chromium coating provides superior wear resistance and hardness, significantly enhancing surface durability in harsh environments or heavy friction conditions. The choice between tin and chromium coatings depends on the specific demands for longevity and abrasion resistance in industrial or consumer products.

Environmental Impact of Tin and Chromium Coatings

Tin coating offers a lower environmental impact compared to chromium coating due to its non-toxic nature and easier recyclability, reducing hazardous waste in industrial applications. Chromium coatings, especially hexavalent chromium, are associated with significant ecological and health risks, including soil and water contamination and increased toxicity during disposal. Regulatory restrictions on chromium usage drive industries toward tin coatings as a sustainable alternative that supports eco-friendly manufacturing practices.

Cost Analysis: Tin Coating vs. Chromium Coating

Tin coating generally offers a more cost-effective solution compared to chromium coating due to lower raw material and processing expenses. Chromium coating involves higher costs linked to complex plating techniques and stringent environmental regulations. Economically, tin coating provides better value for applications requiring corrosion resistance without the premium price associated with chromium finishes.

Choosing the Right Coating for Your Product

Tin coating offers excellent corrosion resistance and solderability, making it ideal for electrical components and food packaging applications. Chromium coating provides superior hardness and wear resistance, suitable for decorative finishes and industrial machinery parts. Selecting the right coating depends on the product's exposure to environmental conditions, required durability, and specific performance needs.

Tin Coating vs Chromium Coating Infographic

materialdif.com

materialdif.com