Tin foil is thin, flexible, and commonly used for wrapping food or insulation, while tin sheets are thicker, rigid, and employed in manufacturing, roofing, and crafting applications. Tin foil offers superior malleability and ease of shaping, making it ideal for short-term use, whereas tin sheets provide greater durability and structural support. Understanding their differences ensures selecting the right material for specific industrial, packaging, or household needs.

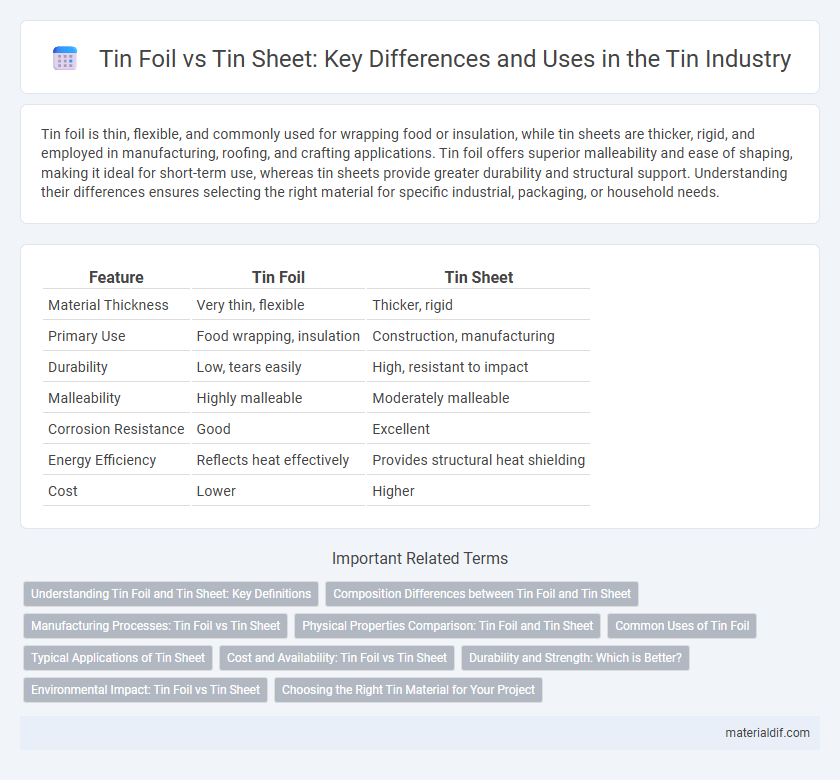

Table of Comparison

| Feature | Tin Foil | Tin Sheet |

|---|---|---|

| Material Thickness | Very thin, flexible | Thicker, rigid |

| Primary Use | Food wrapping, insulation | Construction, manufacturing |

| Durability | Low, tears easily | High, resistant to impact |

| Malleability | Highly malleable | Moderately malleable |

| Corrosion Resistance | Good | Excellent |

| Energy Efficiency | Reflects heat effectively | Provides structural heat shielding |

| Cost | Lower | Higher |

Understanding Tin Foil and Tin Sheet: Key Definitions

Tin foil is an ultra-thin metal sheet primarily used for wrapping and packaging, offering flexibility and moisture resistance, whereas a tin sheet is thicker, providing structural durability for industrial and manufacturing applications. Tin foil typically measures less than 0.025 mm in thickness, while tin sheets are often several millimeters thick, enabling enhanced mechanical strength. Understanding these key definitions helps clarify their distinct roles in packaging, construction, and electronic industries.

Composition Differences between Tin Foil and Tin Sheet

Tin foil primarily consists of pure tin, often exceeding 99% purity, which provides its characteristic flexibility and corrosion resistance, making it ideal for wrapping and food storage. In contrast, tin sheets are typically alloys containing tin combined with metals such as copper or lead to enhance strength and durability for industrial and construction applications. The difference in alloy composition directly influences the mechanical properties and typical uses of tin foil versus tin sheets.

Manufacturing Processes: Tin Foil vs Tin Sheet

Tin foil is produced by rolling tin ingots into extremely thin layers using cold rolling mills, resulting in flexible, lightweight sheets primarily used for packaging and insulation. Tin sheets undergo hot rolling and annealing processes to enhance strength and durability, making them suitable for industrial applications such as roofing and electronics. The key distinction lies in the thickness and mechanical treatments, where tin foil emphasizes thinness and flexibility, and tin sheets focus on structural integrity.

Physical Properties Comparison: Tin Foil and Tin Sheet

Tin foil exhibits a thickness typically below 0.2 mm, resulting in high flexibility and ease of molding around objects, whereas tin sheets range from 0.2 mm to several millimeters, providing enhanced rigidity and structural strength. The density of tin remains constant at around 7.31 g/cm3 for both forms, but the mechanical properties such as tensile strength and hardness significantly increase in tin sheets due to their greater thickness and processing methods. Surface characteristics also differ; tin foil has a smooth, reflective finish ideal for packaging, while tin sheets offer a matte or brushed texture suited for industrial applications requiring durability.

Common Uses of Tin Foil

Tin foil, primarily used for food packaging and preservation, offers excellent resistance to moisture, light, and bacteria, making it ideal for wrapping sandwiches, baking, and storing leftovers. Its thin, flexible nature enables it to form airtight seals, which helps in maintaining food freshness and preventing contamination. Unlike tin sheets, which are thicker and used mainly in industrial applications, tin foil is favored in kitchens for its convenience and protective properties.

Typical Applications of Tin Sheet

Tin sheet is commonly used in packaging industries for making cans and containers due to its corrosion resistance and non-toxic properties. It serves essential roles in electrical components and automotive parts, providing durability and conductivity. Tin sheet is also utilized for decorative purposes and in roofing materials, offering a lightweight and weather-resistant solution.

Cost and Availability: Tin Foil vs Tin Sheet

Tin foil is generally more cost-effective due to its thinness and efficient manufacturing process, making it widely available for everyday use. Tin sheets, being thicker and sturdier, have higher production costs and are less commonly stocked in retail outlets, but they offer greater durability for industrial applications. Both materials are produced primarily from refined tin, yet foil's lightweight nature often results in lower transportation and storage expenses compared to sheets.

Durability and Strength: Which is Better?

Tin sheet offers greater durability and strength compared to tin foil due to its thicker gauge and solid structure, making it more suitable for industrial applications and long-term use. Tin foil, being thin and flexible, is primarily designed for short-term tasks such as food wrapping and insulation but lacks the resilience to withstand heavy mechanical stress. Consequently, for projects requiring robust material, tin sheets provide superior strength and durability over tin foil.

Environmental Impact: Tin Foil vs Tin Sheet

Tin foil, primarily composed of aluminum rather than pure tin, is often used for single-use applications, leading to higher waste generation and limited recyclability compared to tin sheets. Tin sheets, made from solid tin or tin-coated steel, offer greater durability and can be reused or recycled more efficiently, reducing environmental burden. The production processes of tin sheets generally have a lower carbon footprint relative to the frequent manufacturing of tin foil due to their longer lifecycle and reuse potential.

Choosing the Right Tin Material for Your Project

Tin foil offers flexibility and lightweight properties ideal for food wrapping and insulation, while tin sheets provide durability and structural strength suitable for roofing, packaging, and crafting. Selecting the right tin material depends on project demands such as thickness, malleability, and resistance to corrosion. Understanding these functional differences ensures optimal performance and longevity in applications ranging from kitchen use to industrial fabrication.

Tin foil vs Tin sheet Infographic

materialdif.com

materialdif.com