A soldered seam in a tin pet creates a strong bond by melting a filler metal, offering flexibility and ease of repair but with lower strength compared to welding. A welded seam fuses the metal edges directly, resulting in a more durable and airtight joint, ideal for high-pressure or high-stress applications. Choosing between soldered and welded seams depends on the pet container's intended use, balancing durability requirements and manufacturing costs.

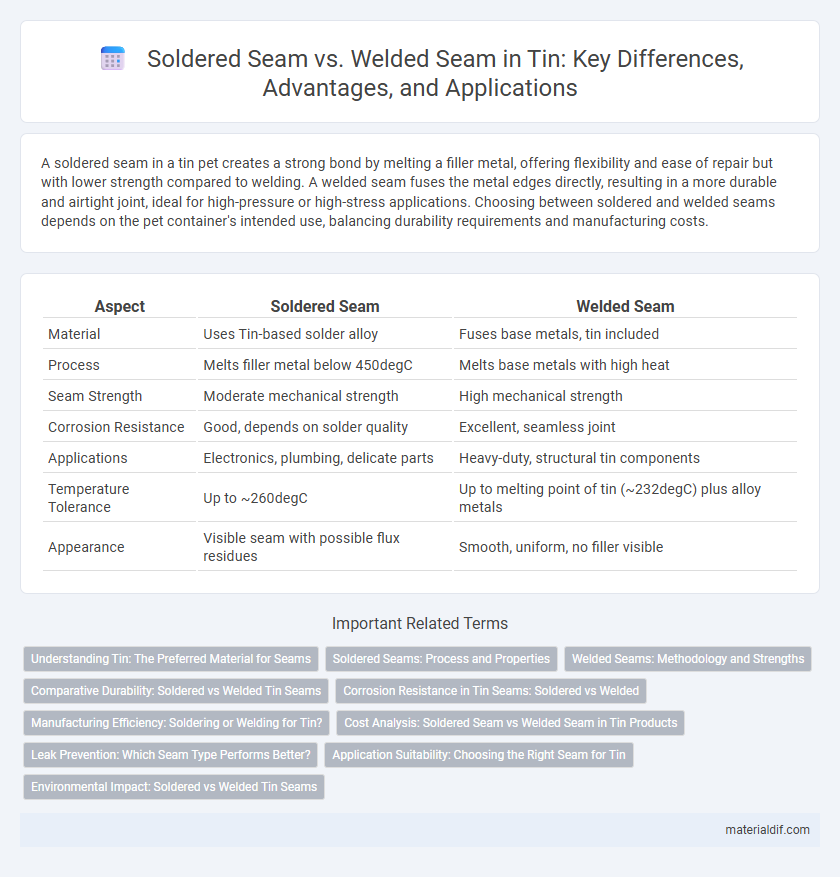

Table of Comparison

| Aspect | Soldered Seam | Welded Seam |

|---|---|---|

| Material | Uses Tin-based solder alloy | Fuses base metals, tin included |

| Process | Melts filler metal below 450degC | Melts base metals with high heat |

| Seam Strength | Moderate mechanical strength | High mechanical strength |

| Corrosion Resistance | Good, depends on solder quality | Excellent, seamless joint |

| Applications | Electronics, plumbing, delicate parts | Heavy-duty, structural tin components |

| Temperature Tolerance | Up to ~260degC | Up to melting point of tin (~232degC) plus alloy metals |

| Appearance | Visible seam with possible flux residues | Smooth, uniform, no filler visible |

Understanding Tin: The Preferred Material for Seams

Tin's excellent corrosion resistance and ductility make it the preferred material for soldered seams, ensuring a reliable, leak-proof joint without the intense heat required for welding. Soldered seams with tin maintain the integrity of delicate components by avoiding thermal distortion typical in welded seams. While welded seams provide strong mechanical bonds, tin soldered seams offer superior electrical conductivity and flexibility essential for delicate electronic and plumbing applications.

Soldered Seams: Process and Properties

Soldered seams in tin involve melting a filler metal, typically a tin-lead or tin-silver alloy, at a lower temperature than the base metals to join surfaces without melting them. This process allows for strong, corrosion-resistant joints with minimal thermal distortion, making it ideal for delicate electronic assemblies and food-grade containers. The resulting seam exhibits good electrical conductivity, mechanical strength, and excellent resistance to oxidation, ensuring durability and reliability in various industrial and consumer applications.

Welded Seams: Methodology and Strengths

Welded seams in tin joining utilize heat to fuse materials at a molecular level, creating a continuous metal bond that significantly enhances structural integrity. This methodology involves techniques such as TIG (Tungsten Inert Gas) or laser welding, which ensure deep penetration and minimal distortion compared to soldering. The resulting welds offer superior mechanical strength, corrosion resistance, and durability, making welded seams ideal for applications requiring robust, long-lasting tin joints.

Comparative Durability: Soldered vs Welded Tin Seams

Welded tin seams exhibit superior durability compared to soldered seams due to the fusion of base metals that create a continuous, strong bond resistant to mechanical stress and corrosion. Soldered seams rely on a filler metal with lower melting points, resulting in weaker joints more susceptible to thermal cycling and environmental degradation. In applications demanding high structural integrity and longevity, welded tin seams outperform soldered ones by maintaining stability under harsh conditions.

Corrosion Resistance in Tin Seams: Soldered vs Welded

Soldered seams in tin joints offer moderate corrosion resistance due to the presence of solder alloys that can be susceptible to galvanic corrosion when exposed to moisture and corrosive environments. Welded seams, where tin is fused directly, create a homogeneous metallic bond that provides superior corrosion resistance by eliminating the dissimilar metal interfaces found in soldered joints. This continuous weld seam is less prone to crevice corrosion and ensures enhanced durability in tin-based applications requiring long-term exposure to harsh conditions.

Manufacturing Efficiency: Soldering or Welding for Tin?

Soldered seams in tin manufacturing offer faster processing times and lower energy consumption compared to welded seams, making them ideal for high-volume production. However, welded seams provide superior mechanical strength and corrosion resistance, crucial for applications requiring durability and longevity. Choosing between soldering and welding depends on balancing manufacturing efficiency with the specific performance requirements of the tin product.

Cost Analysis: Soldered Seam vs Welded Seam in Tin Products

Soldered seams in tin products generally offer lower initial costs due to simpler equipment and reduced energy consumption compared to welded seams. Welded seams, while incurring higher upfront expenses, provide greater durability and strength, potentially lowering long-term maintenance and replacement costs. Cost analysis must consider production volume, material thickness, and product application to determine the most economically viable option for tin fabrication.

Leak Prevention: Which Seam Type Performs Better?

Soldered seams using tin provide reliable leak prevention for low-pressure applications due to tin's excellent wetting properties and ability to form a tight, corrosion-resistant bond. Welded seams, however, create a continuous metal joint that offers superior strength and leak-tightness, especially under high pressure or thermal stress. For critical leak prevention in demanding environments, welded seams outperform soldered seams by ensuring a more robust and durable seal.

Application Suitability: Choosing the Right Seam for Tin

Soldered seams in tin applications offer precise control and are ideal for delicate electronic components due to their lower temperature requirements and ability to create strong, conductive joints without damaging heat-sensitive parts. Welded seams provide superior mechanical strength and are preferred in structural uses or where high durability against stress and corrosion is essential, such as in tin-plated steel containers or pipes. Selecting between soldered and welded seams depends on balancing the need for electrical conductivity, mechanical integrity, and thermal tolerance specific to the tin application.

Environmental Impact: Soldered vs Welded Tin Seams

Soldered tin seams typically use lower temperatures, reducing energy consumption and limiting harmful emissions compared to welded seams. Welding tin seams often requires higher heat input, resulting in greater carbon footprint and potential release of toxic fumes. Choosing soldering over welding can minimize environmental impact by conserving energy and reducing pollutant generation in tin joining processes.

Soldered seam vs Welded seam Infographic

materialdif.com

materialdif.com