White tin and gray tin are two allotropes of tin with distinct physical properties and stability ranges. White tin is metallic, ductile, and stable at temperatures above 13.2degC, whereas gray tin is non-metallic, brittle, and forms below this transformation temperature. The conversion between these forms, known as "tin pest," can cause structural degradation in tin-coated materials, making the choice between white and gray tin critical for durability.

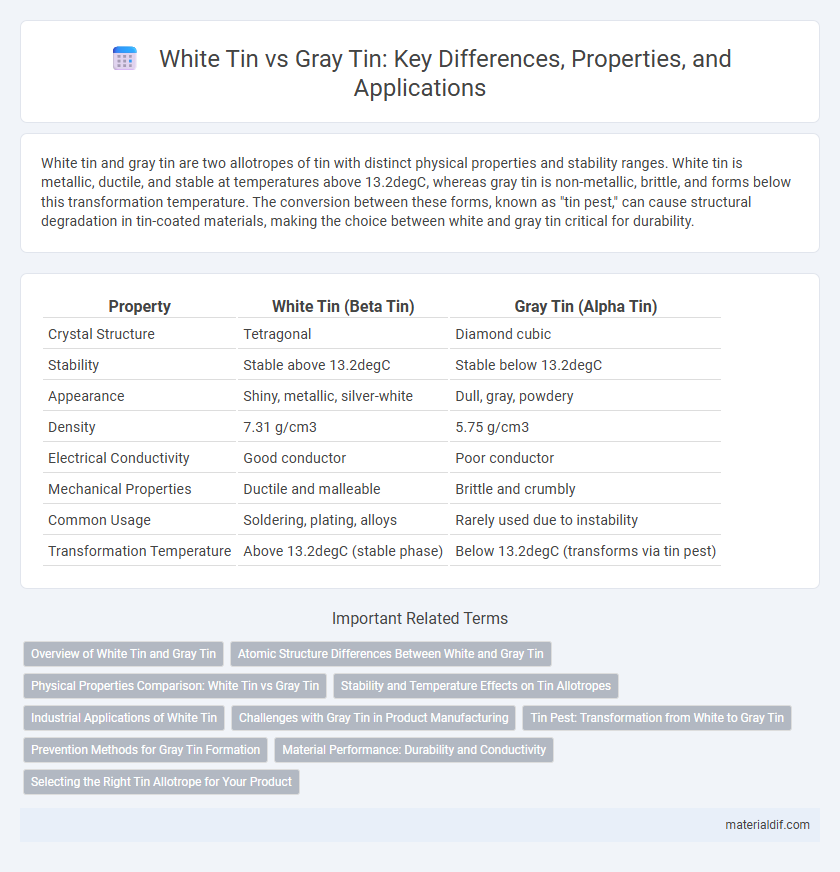

Table of Comparison

| Property | White Tin (Beta Tin) | Gray Tin (Alpha Tin) |

|---|---|---|

| Crystal Structure | Tetragonal | Diamond cubic |

| Stability | Stable above 13.2degC | Stable below 13.2degC |

| Appearance | Shiny, metallic, silver-white | Dull, gray, powdery |

| Density | 7.31 g/cm3 | 5.75 g/cm3 |

| Electrical Conductivity | Good conductor | Poor conductor |

| Mechanical Properties | Ductile and malleable | Brittle and crumbly |

| Common Usage | Soldering, plating, alloys | Rarely used due to instability |

| Transformation Temperature | Above 13.2degC (stable phase) | Below 13.2degC (transforms via tin pest) |

Overview of White Tin and Gray Tin

White tin (beta tin) is the metallic, stable form of tin at room temperature, characterized by its shiny, silvery appearance and ductile properties used widely in soldering and plating applications. Gray tin (alpha tin) forms at temperatures below 13.2degC, exhibiting a brittle, powdery, non-metallic allotrope with a diamond cubic crystal structure, often considered a degradation phase reducing tin's mechanical integrity. The phase transition between white and gray tin significantly impacts tin's industrial performance, especially in cold environments.

Atomic Structure Differences Between White and Gray Tin

White tin (b-tin) features a tetragonal crystal structure with atoms tightly packed, allowing greater electrical conductivity and metallic properties. In contrast, gray tin (a-tin) exhibits a diamond cubic structure where atoms are arranged more loosely, resulting in a brittle, semiconducting nature. These atomic structure differences cause white tin to be stable at room temperature, while gray tin becomes stable below 13.2degC, significantly altering physical and electrical characteristics.

Physical Properties Comparison: White Tin vs Gray Tin

White tin, or beta tin, exhibits a metallic luster with a tetragonal crystal structure, maintaining ductility and electrical conductivity at room temperature. Gray tin, or alpha tin, has a diamond cubic crystal structure, appearing brittle and non-metallic with lower density and poor electrical conductivity. The transformation from white to gray tin occurs below 13.2 degC, causing significant changes in hardness, brittleness, and mechanical properties.

Stability and Temperature Effects on Tin Allotropes

White tin (b-tin) is the stable allotrope of tin at temperatures above 13.2degC, exhibiting a metallic structure with high electrical conductivity and ductility. Gray tin (a-tin) forms below 13.2degC, possessing a brittle, diamond cubic semiconductor structure that causes white tin to transform and expand, leading to material degradation known as tin pest. The phase transition between these allotropes is highly temperature-dependent, with the stability of white tin favored at ambient and elevated temperatures, while gray tin predominates under prolonged exposure to low temperatures.

Industrial Applications of White Tin

White tin, also known as beta-tin, is widely used in industrial applications due to its metallic luster, malleability, and resistance to corrosion. It serves as a crucial component in solder alloys, coatings for steel cans, and tin plating processes that protect against rust and enhance durability. Compared to gray tin, which is brittle and non-metallic, white tin maintains structural integrity under typical industrial conditions, making it essential for electronics, packaging, and automotive industries.

Challenges with Gray Tin in Product Manufacturing

Gray tin, a brittle allotrope of tin that forms at low temperatures below 13.2degC, poses significant challenges in product manufacturing due to its propensity to cause tin pest, a phase transition that leads to disintegration and loss of mechanical integrity. The transformation from white tin to gray tin results in volume expansion, causing cracks and weakening structural components, which is particularly problematic in electronic soldering and precision instruments. Controlling ambient temperature and alloying tin with metals like antimony or copper are essential strategies to mitigate the degradation risks associated with gray tin in industrial applications.

Tin Pest: Transformation from White to Gray Tin

Tin undergoes a phase transformation known as Tin Pest, where metallic white tin (b-tin) converts into brittle, non-metallic gray tin (a-tin) at temperatures below 13.2degC. This allotropic change causes a volume expansion of about 27%, leading to material disintegration and loss of mechanical integrity in tin-based components. Understanding the kinetics and environmental conditions of this transformation is critical for preventing degradation in electronics and solder alloys exposed to cold environments.

Prevention Methods for Gray Tin Formation

Gray tin forms when white tin undergoes a phase transformation at low temperatures, causing brittleness and structural failure. Prevention methods include alloying white tin with metals like antimony, bismuth, or copper to stabilize its metallic structure and reduce susceptibility to the transformation. Maintaining operating temperatures above 13.2degC and applying protective coatings further inhibit the formation of gray tin.

Material Performance: Durability and Conductivity

White tin offers superior durability and high electrical conductivity, making it ideal for electronic components and soldering applications. Gray tin, a brittle allotrope stable at low temperatures, exhibits poor mechanical strength and significantly reduced conductivity, limiting its practical use. The material performance disparity between white and gray tin critically influences their selection in industrial and technological contexts.

Selecting the Right Tin Allotrope for Your Product

White tin, stable at room temperature, exhibits excellent ductility and conductivity, making it ideal for soldering and plating applications. Gray tin, a brittle semiconductor form appearing below 13.2degC, is generally avoided in manufacturing due to its structural instability and poor mechanical properties. Selecting the right tin allotrope requires considering operating temperatures and mechanical demands to ensure product reliability and performance.

White tin vs gray tin Infographic

materialdif.com

materialdif.com