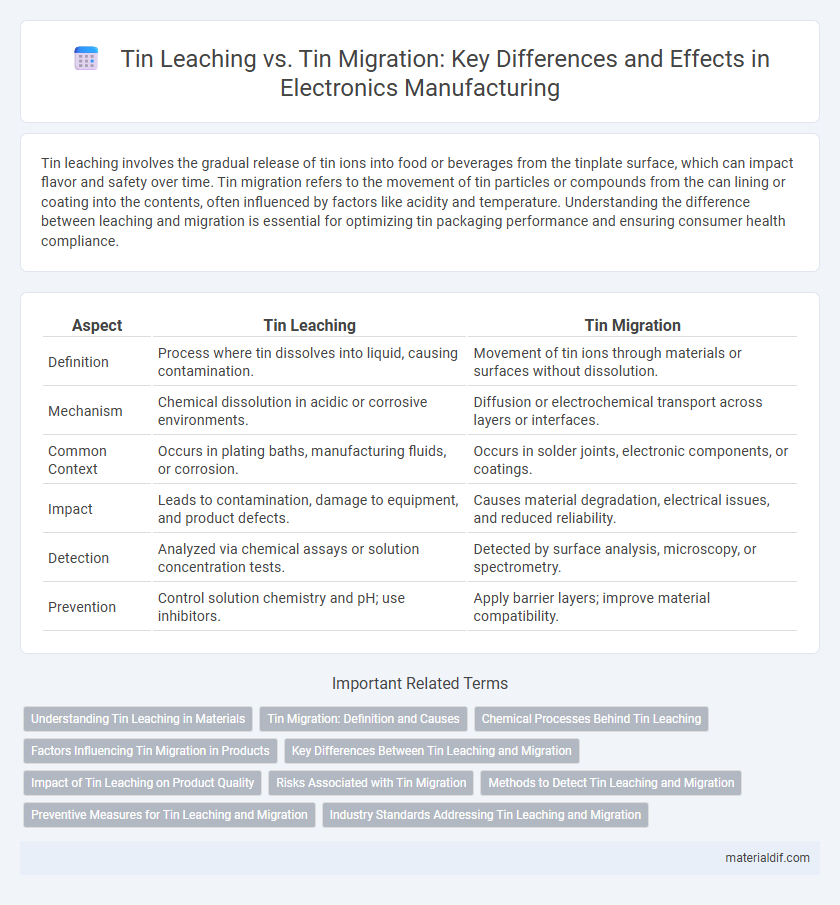

Tin leaching involves the gradual release of tin ions into food or beverages from the tinplate surface, which can impact flavor and safety over time. Tin migration refers to the movement of tin particles or compounds from the can lining or coating into the contents, often influenced by factors like acidity and temperature. Understanding the difference between leaching and migration is essential for optimizing tin packaging performance and ensuring consumer health compliance.

Table of Comparison

| Aspect | Tin Leaching | Tin Migration |

|---|---|---|

| Definition | Process where tin dissolves into liquid, causing contamination. | Movement of tin ions through materials or surfaces without dissolution. |

| Mechanism | Chemical dissolution in acidic or corrosive environments. | Diffusion or electrochemical transport across layers or interfaces. |

| Common Context | Occurs in plating baths, manufacturing fluids, or corrosion. | Occurs in solder joints, electronic components, or coatings. |

| Impact | Leads to contamination, damage to equipment, and product defects. | Causes material degradation, electrical issues, and reduced reliability. |

| Detection | Analyzed via chemical assays or solution concentration tests. | Detected by surface analysis, microscopy, or spectrometry. |

| Prevention | Control solution chemistry and pH; use inhibitors. | Apply barrier layers; improve material compatibility. |

Understanding Tin Leaching in Materials

Tin leaching refers to the process where tin ions dissolve from a material, often due to environmental factors such as moisture or acidity, leading to a reduction in material integrity and potential contamination. This phenomenon differs from tin migration, which involves the physical movement of tin particles within or between materials without necessarily dissolving. Understanding tin leaching is critical in industries like packaging and electronics, as it impacts the longevity and safety of tin-coated products by causing corrosion and releasing tin into contact substances.

Tin Migration: Definition and Causes

Tin migration refers to the movement of tin ions from a tin-coated surface into adjacent materials, often occurring in electronic components with tin plating. This phenomenon is primarily caused by environmental factors such as humidity, temperature variations, and the presence of ionic contaminants that facilitate ion diffusion. Unlike tin leaching, which involves the dissolution of tin into a solution, tin migration leads to the formation of conductive tin whiskers or dendrites that can cause short circuits and reliability issues in electronic assemblies.

Chemical Processes Behind Tin Leaching

Tin leaching involves the chemical dissolution of tin from a solid matrix into a liquid, primarily driven by oxidation-reduction reactions where tin metal oxidizes to soluble tin ions such as Sn2+ or Sn4+. This process depends on factors like pH, temperature, and the presence of complexing agents or oxidants that facilitate the conversion of elemental tin into its ionic forms. Tin migration, in contrast, refers to the physical transport of tin ions or tin-containing compounds through materials without necessarily involving a chemical transformation.

Factors Influencing Tin Migration in Products

Factors influencing tin migration in products include temperature, acidity, and contact duration, which accelerate the dissolution of tin into the product. The type of packaging material, such as tin-coated steel or tin-free steel, also plays a significant role in determining the extent of tin leaching. Product composition, especially the presence of salt or organic acids, further impacts the rate and amount of tin migrating into the product.

Key Differences Between Tin Leaching and Migration

Tin leaching involves the chemical dissolution of tin from packaging or containers into food or beverages, often influenced by factors like acidity and temperature. In contrast, tin migration refers to the physical transfer of tin particles or ions from packaging materials to the product without significant chemical alteration. The key difference lies in leaching being a chemical process causing tin ions to dissolve, whereas migration is a physical movement of tin components into the food matrix.

Impact of Tin Leaching on Product Quality

Tin leaching significantly affects product quality by introducing metallic impurities and off-flavors, compromising taste and safety in packaged goods like canned foods and beverages. This chemical interaction can accelerate corrosion of packaging materials, leading to reduced shelf life and potential contamination. Controlling tin leaching through protective coatings and optimal storage conditions is essential to maintain product integrity and consumer trust.

Risks Associated with Tin Migration

Tin migration poses significant health risks due to the contamination of food and beverages with soluble tin compounds, potentially leading to gastrointestinal issues and toxicity. Unlike tin leaching, which involves the release of tin particles typically within safe limits, tin migration results in higher concentrations of tin ions that can exceed regulatory safety thresholds. Prolonged exposure to migrated tin can cause acute symptoms such as nausea, vomiting, and abdominal pain, emphasizing the importance of monitoring tin migration in food packaging materials.

Methods to Detect Tin Leaching and Migration

Tin leaching and migration in packaging materials are primarily detected using analytical techniques such as inductively coupled plasma mass spectrometry (ICP-MS) and atomic absorption spectroscopy (AAS), which measure tin concentration in food simulants or actual food samples. Methods like X-ray fluorescence (XRF) and laser ablation ICP-MS enable surface analysis to monitor tin migration from coatings into products. Advanced chromatographic methods combined with mass spectrometry can identify organotin compounds, distinguishing between inorganic tin leaching and tin migration pathways.

Preventive Measures for Tin Leaching and Migration

Preventive measures for tin leaching and migration primarily involve controlling the acidity and storage conditions of food products in tin-plated containers, as high acidity accelerates tin dissolution. Applying protective coatings inside cans and using modern tin-free steel can liners significantly reduce direct contact between tin surfaces and food, minimizing migration risks. Regular monitoring of packaging integrity and adherence to industry standards ensures consistent prevention of tin contamination in food products.

Industry Standards Addressing Tin Leaching and Migration

Industry standards such as IPC-TM-650 and JESD22-A113 provide guidelines for testing and mitigating tin leaching and tin migration in electronic components, ensuring reliable solder joints and preventing circuit failures. Compliance with IPC-4552 and JESD22-A113 standards is critical to control tin whisker growth and ion migration, which can lead to short circuits and device degradation. Manufacturers implement these standards alongside environmental regulations like RoHS to minimize tin-related reliability issues in electronics assembly.

Tin Leaching vs Tin Migration Infographic

materialdif.com

materialdif.com