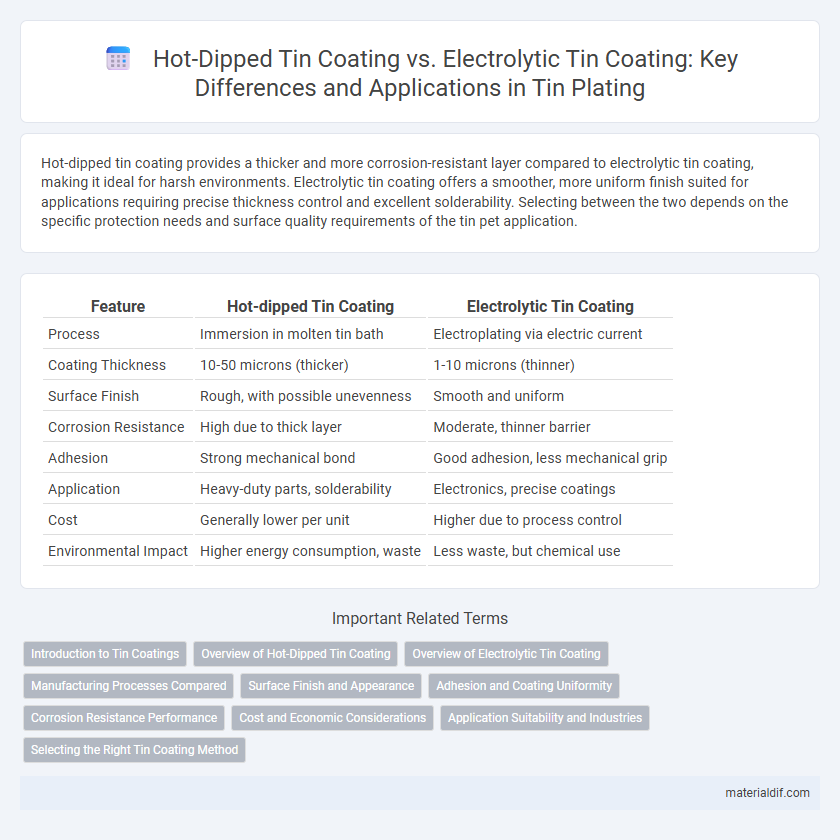

Hot-dipped tin coating provides a thicker and more corrosion-resistant layer compared to electrolytic tin coating, making it ideal for harsh environments. Electrolytic tin coating offers a smoother, more uniform finish suited for applications requiring precise thickness control and excellent solderability. Selecting between the two depends on the specific protection needs and surface quality requirements of the tin pet application.

Table of Comparison

| Feature | Hot-dipped Tin Coating | Electrolytic Tin Coating |

|---|---|---|

| Process | Immersion in molten tin bath | Electroplating via electric current |

| Coating Thickness | 10-50 microns (thicker) | 1-10 microns (thinner) |

| Surface Finish | Rough, with possible unevenness | Smooth and uniform |

| Corrosion Resistance | High due to thick layer | Moderate, thinner barrier |

| Adhesion | Strong mechanical bond | Good adhesion, less mechanical grip |

| Application | Heavy-duty parts, solderability | Electronics, precise coatings |

| Cost | Generally lower per unit | Higher due to process control |

| Environmental Impact | Higher energy consumption, waste | Less waste, but chemical use |

Introduction to Tin Coatings

Tin coatings enhance corrosion resistance and solderability in metal substrates, with hot-dipped and electrolytic methods serving distinct industrial applications. Hot-dipped tin coating involves immersing the metal in molten tin, forming a robust, thick layer ideal for heavy-duty protection. Electrolytic tin coating uses an electric current to deposit a thinner, more uniform tin layer, providing excellent surface finish and precise thickness control for electronic components.

Overview of Hot-Dipped Tin Coating

Hot-dipped tin coating involves immersing metal substrates into molten tin, creating a robust, uniform layer that offers superior corrosion resistance and excellent solderability. This method produces a thicker coating compared to electrolytic tin plating, enhancing mechanical protection and extending the lifespan of electronic components, connectors, and steel parts. Hot-dipped tin coatings are widely used in harsh environments due to their durability and ability to withstand thermal and mechanical stresses.

Overview of Electrolytic Tin Coating

Electrolytic tin coating involves the deposition of tin onto a metal substrate using an electrolytic process, resulting in a uniform, dense, and adherent tin layer that enhances corrosion resistance and solderability. This method allows precise control over coating thickness, typically ranging from 0.1 to 10 microns, making it ideal for fine electronic components and connectors. Its superior surface finish and stability under thermal cycling distinguish it from hot-dipped tin coating, which tends to have thicker and less uniform layers.

Manufacturing Processes Compared

Hot-dipped tin coating involves immersing the substrate into a molten tin bath, creating a thick, uniform layer with excellent corrosion resistance, ideal for heavy-duty applications. In contrast, electrolytic tin coating uses an electroplating process where tin ions are deposited onto the substrate through an electric current, allowing precise thickness control and better surface finish for electronic components. The manufacturing speed of hot-dipped coating is generally faster but less uniform, while electrolytic coating offers tight thickness tolerances and superior adhesion on complex geometries.

Surface Finish and Appearance

Hot-dipped tin coating produces a thicker, more robust surface finish with a slightly matte and irregular appearance due to the molten tin immersion process. Electrolytic tin coating yields a thinner, smoother, and highly uniform surface finish, resulting in a bright, shiny, and visually consistent appearance. The choice between these coatings depends on the desired balance between corrosion resistance, surface aesthetic, and coating thickness.

Adhesion and Coating Uniformity

Hot-dipped tin coating typically provides superior adhesion due to the metallurgical bonding formed during the dipping process, resulting in a more durable and corrosion-resistant layer. Electrolytic tin coating offers enhanced coating uniformity and precise thickness control, crucial for applications requiring consistent surface quality. Both methods have distinct advantages depending on the priority given to adhesion strength or coating uniformity in tin-plated products.

Corrosion Resistance Performance

Hot-dipped tin coating offers superior corrosion resistance due to its thicker and more uniform layer, providing enhanced protection against oxidation and environmental factors. Electrolytic tin coating, while thinner, provides a cleaner and smoother finish but may be less effective in harsh corrosive conditions. The choice between these coatings depends on the required durability and exposure environment, with hot-dipped tin preferred for heavy-duty applications demanding long-term corrosion protection.

Cost and Economic Considerations

Hot-dipped tin coating generally incurs higher initial costs due to greater material usage and thicker coating layers, providing enhanced corrosion resistance and longer lifespan. Electrolytic tin coating offers a more cost-effective solution with lower material consumption and precision control over coating thickness, reducing waste and processing time. Choosing between the two depends on balancing upfront investment against long-term durability and maintenance expenses in tin plating applications.

Application Suitability and Industries

Hot-dipped tin coating provides a thick, uniform layer ideal for heavy-duty corrosion protection in industries such as automotive and construction, where robust mechanical durability is crucial. Electrolytic tin coating offers precision control over thickness, making it suitable for the electronics and packaging industries where fine detailing and surface finish are essential. Both coatings serve different industrial demands, with hot-dipped tin favored for protection in harsh environments and electrolytic tin preferred for high-precision applications.

Selecting the Right Tin Coating Method

Hot-dipped tin coating provides a thicker, more robust layer ideal for corrosion resistance in harsh environments, making it suitable for automotive and heavy-duty applications. Electrolytic tin coating offers a finer, more uniform finish with precise thickness control, preferred for electronic components and delicate assemblies. Selecting the right tin coating method depends on application requirements, including durability, conductivity, and environmental exposure.

Hot-dipped Tin Coating vs Electrolytic Tin Coating Infographic

materialdif.com

materialdif.com