Hot-dipped tinning involves immersing the base metal in molten tin, creating a thicker and more durable coating ideal for corrosion resistance in harsh environments. Electro-tinning uses an electrolytic process to deposit a thinner and more uniform layer of tin, which offers better adhesion and is suitable for precise electronic applications. Choosing between hot-dipped tinning and electro-tinning depends on the desired coating thickness, durability requirements, and application-specific needs.

Table of Comparison

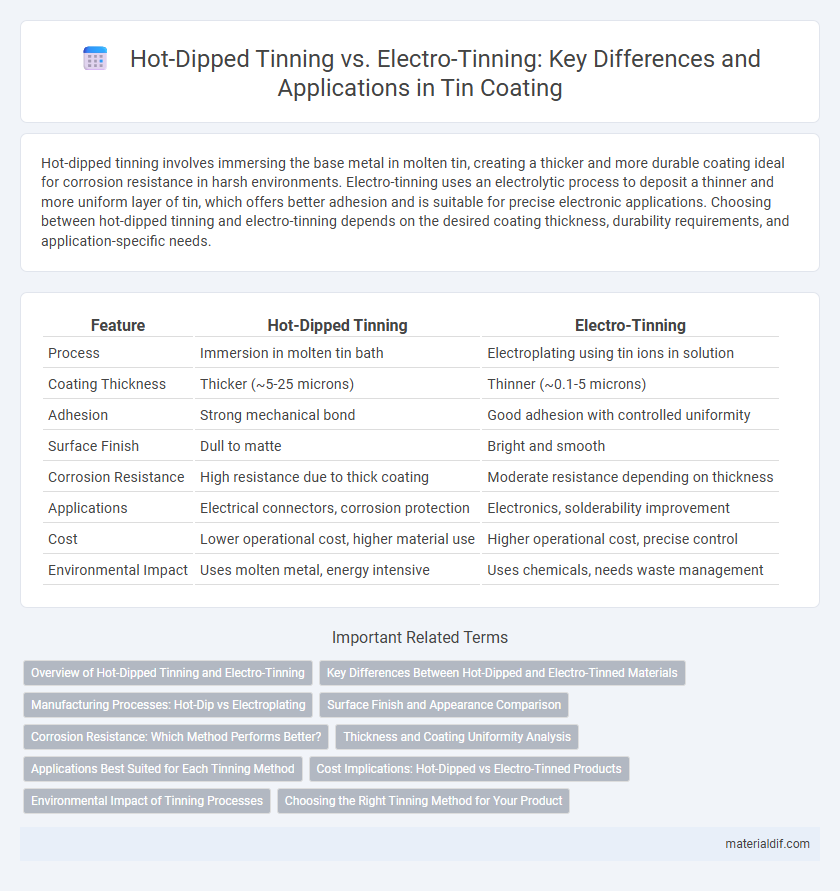

| Feature | Hot-Dipped Tinning | Electro-Tinning |

|---|---|---|

| Process | Immersion in molten tin bath | Electroplating using tin ions in solution |

| Coating Thickness | Thicker (~5-25 microns) | Thinner (~0.1-5 microns) |

| Adhesion | Strong mechanical bond | Good adhesion with controlled uniformity |

| Surface Finish | Dull to matte | Bright and smooth |

| Corrosion Resistance | High resistance due to thick coating | Moderate resistance depending on thickness |

| Applications | Electrical connectors, corrosion protection | Electronics, solderability improvement |

| Cost | Lower operational cost, higher material use | Higher operational cost, precise control |

| Environmental Impact | Uses molten metal, energy intensive | Uses chemicals, needs waste management |

Overview of Hot-Dipped Tinning and Electro-Tinning

Hot-dipped tinning involves immersing metal substrates in molten tin at temperatures around 250degC, creating a thick, robust coating ideal for corrosion resistance in industrial applications. Electro-tinning uses electroplating techniques where tin ions are deposited onto the substrate in an electrolytic bath, producing a thinner, more uniform layer favored for electronic components. Both methods enhance solderability and protect against oxidation, with hot-dipped tinning offering superior durability and electro-tinning providing precise control over coating thickness.

Key Differences Between Hot-Dipped and Electro-Tinned Materials

Hot-dipped tinning involves immersing the substrate into molten tin, creating a thicker, more corrosion-resistant coating ideal for heavy-duty applications, while electro-tinning uses an electrical current to deposit a thinner, uniform tin layer suited for precision electronic components. Hot-dipped coatings have superior mechanical strength and better adhesion but less surface smoothness compared to the finer finish and better dimensional control achieved with electro-tinning. The choice between hot-dipped and electro-tinned materials depends on the required corrosion resistance, coating thickness, and surface quality for the specific industrial use.

Manufacturing Processes: Hot-Dip vs Electroplating

Hot-dipped tinning involves immersing a substrate in molten tin at high temperatures, creating a thick, durable coating that ensures excellent corrosion resistance and mechanical bonding. Electro-tinning uses an electroplating process where tin ions are deposited onto the substrate surface through an electrolytic bath, allowing precise control over coating thickness and uniformity. The choice between hot-dip and electroplating depends on application requirements, with hot-dipping favored for heavy-duty protection and electro-tinning preferred for fine, decorative finishes.

Surface Finish and Appearance Comparison

Hot-dipped tinning produces a thicker, more uniform tin coating with a matte or dull finish, offering enhanced corrosion resistance and durability. Electro-tinning yields a thinner, smoother, and shinier surface finish with fine grain texture, ideal for decorative applications requiring bright appearance. The choice between hot-dipped and electro-tinning depends on the desired surface aesthetics and functional performance in corrosion protection.

Corrosion Resistance: Which Method Performs Better?

Hot-dipped tinning provides superior corrosion resistance by forming a thicker, more uniform tin layer that offers enhanced protection against oxidation and environmental factors. Electro-tinning deposits a thinner, more controlled tin coating, which is less effective in harsh or highly corrosive environments but allows for greater precision in electronics and delicate components. Therefore, hot-dipped tinning generally outperforms electro-tinning in corrosion resistance, especially in industrial applications exposed to moisture and chemicals.

Thickness and Coating Uniformity Analysis

Hot-dipped tinning typically produces a thicker tin coating, ranging from 5 to 20 microns, offering superior corrosion resistance, whereas electro-tinning generally yields thinner layers between 1 to 10 microns. The coating uniformity in electro-tinning is more controlled and consistent due to precise electrical current regulation, leading to better surface smoothness and adherence compared to the variable thickness seen in hot-dip processes. Analytical techniques such as scanning electron microscopy (SEM) and X-ray fluorescence (XRF) confirm that electro-tinning ensures homogenous coatings essential for fine electronic applications, while hot-dipped tinning suits heavy-duty corrosion protection due to its robust layer.

Applications Best Suited for Each Tinning Method

Hot-dipped tinning is best suited for heavy-duty applications requiring thick, durable coatings to protect steel parts exposed to harsh environments, such as automotive components, wire rods, and large hardware. Electro-tinning provides a thinner, more uniform layer ideal for precision electronic components, food packaging, and small fasteners where corrosion resistance and surface finish are critical. Selecting between hot-dipped and electro-tinning depends on factors like coating thickness, application environment, and desired aesthetics or electrical conductivity.

Cost Implications: Hot-Dipped vs Electro-Tinned Products

Hot-dipped tinning generally incurs higher initial costs due to the extensive use of molten tin and energy consumption, making it more expensive than electro-tinning. Electro-tinning offers cost efficiency through precise control of tin layer thickness and lower material waste, reducing overall production expenses. However, the choice between hot-dipped and electro-tinned products depends on application requirements, with hot-dipped coatings providing superior corrosion resistance at a premium price.

Environmental Impact of Tinning Processes

Hot-dipped tinning consumes more energy and produces higher emissions due to prolonged heating, increasing its environmental footprint compared to electro-tinning. Electro-tinning generates less hazardous waste by using controlled electrical currents and reducing chemical usage, making it a more sustainable option. Advancements in electro-tinning technology further minimize water contamination and improve recyclability of tin-coated materials.

Choosing the Right Tinning Method for Your Product

Hot-dipped tinning provides a thicker, more durable coating ideal for corrosion resistance in heavy-duty applications, while electro-tinning offers a thinner, more uniform layer suitable for precise electronic components and decorative finishes. Selecting the right tinning method depends on factors such as desired coating thickness, adhesion requirements, production volume, and cost efficiency. Understanding the specific environmental and mechanical stresses your product will face ensures optimal performance and longevity.

Hot-dipped tinning vs Electro-tinning Infographic

materialdif.com

materialdif.com