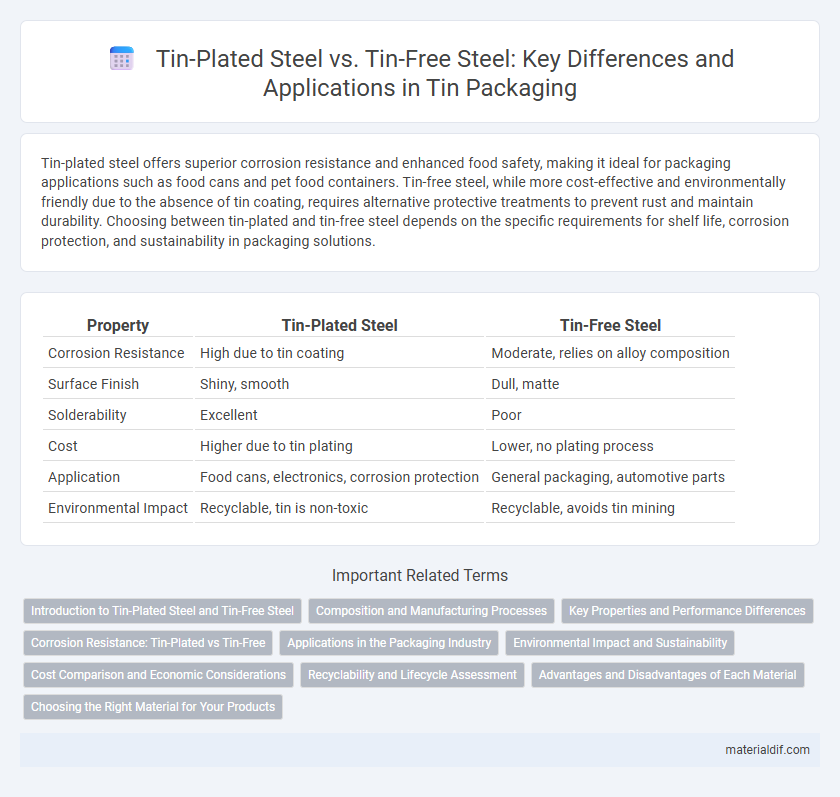

Tin-plated steel offers superior corrosion resistance and enhanced food safety, making it ideal for packaging applications such as food cans and pet food containers. Tin-free steel, while more cost-effective and environmentally friendly due to the absence of tin coating, requires alternative protective treatments to prevent rust and maintain durability. Choosing between tin-plated and tin-free steel depends on the specific requirements for shelf life, corrosion protection, and sustainability in packaging solutions.

Table of Comparison

| Property | Tin-Plated Steel | Tin-Free Steel |

|---|---|---|

| Corrosion Resistance | High due to tin coating | Moderate, relies on alloy composition |

| Surface Finish | Shiny, smooth | Dull, matte |

| Solderability | Excellent | Poor |

| Cost | Higher due to tin plating | Lower, no plating process |

| Application | Food cans, electronics, corrosion protection | General packaging, automotive parts |

| Environmental Impact | Recyclable, tin is non-toxic | Recyclable, avoids tin mining |

Introduction to Tin-Plated Steel and Tin-Free Steel

Tin-plated steel features a thin layer of tin coating applied to steel to provide enhanced corrosion resistance and improved solderability, widely used in food packaging and electronic components. Tin-free steel (TFS), coated with a chromium-based compound instead of tin, offers superior corrosion protection and recyclability, making it a cost-effective alternative in can manufacturing. Both materials balance durability and protection, but tin-plated steel excels in applications requiring solderability, while tin-free steel is preferred for environmentally friendly, high-strength packaging solutions.

Composition and Manufacturing Processes

Tin-plated steel consists of a base steel sheet coated with a thin layer of tin through electroplating or hot-dipping processes, enhancing corrosion resistance and solderability. Tin-free steel, also known as electrolytic chromium coated steel (ECCS), replaces the tin layer with a complex chromium and chromium oxide coating applied via electrochemical deposition, providing excellent corrosion resistance without the need for tin. Manufacturing tin-plated steel involves dipping steel into molten tin or electro-depositing tin, whereas tin-free steel is processed through electrochemical treatments that bond chromium compounds directly onto the steel surface.

Key Properties and Performance Differences

Tin-plated steel offers superior corrosion resistance and enhanced solderability due to its thin layer of tin coating, making it ideal for food packaging and electronic components. Tin-free steel, often coated with chromium or zinc instead, provides a more cost-effective solution with good rust protection but lacks the improved surface adhesion and conductivity found in tin-plated options. Performance differences primarily revolve around corrosion protection, surface finish, and suitability for specific applications such as food contact safety versus industrial use.

Corrosion Resistance: Tin-Plated vs Tin-Free

Tin-plated steel offers superior corrosion resistance due to its protective tin coating that acts as a barrier against moisture and oxygen, preventing rust formation. Tin-free steel, lacking this coating, relies on other treatments like chromium or organic coatings but generally exhibits lower corrosion resistance compared to tin-plated steel. The enhanced durability of tin-plated steel makes it ideal for packaging applications requiring extended shelf life and protection against environmental factors.

Applications in the Packaging Industry

Tin-plated steel is extensively used in the packaging industry for food and beverage cans due to its excellent corrosion resistance and ability to preserve product freshness. Tin-free steel, coated with chromium or chromium oxide, offers a cost-effective alternative with improved paint adhesion, making it ideal for non-food packaging and decorative applications. Both materials provide crucial benefits in packaging durability, but tin-plated steel remains preferred for direct food contact.

Environmental Impact and Sustainability

Tin-plated steel offers enhanced corrosion resistance, extending product lifespan and reducing waste, while its recycling process remains efficient due to the recoverability of both steel and tin components. Tin-free steel, also known as cold-rolled steel, eliminates the use of tin, lowering reliance on tin mining which often involves environmentally harmful practices, yet may require additional coatings that impact recyclability and raise environmental concerns. Assessing sustainability, tin-plated steel supports circular economy principles through recyclability and durability, whereas tin-free steel's environmental footprint depends largely on the alternative coatings applied and their lifecycle impacts.

Cost Comparison and Economic Considerations

Tin-plated steel generally incurs higher manufacturing costs due to the additional tin coating process, which enhances corrosion resistance and extends product lifespan. Tin-free steel offers a cost-effective alternative by eliminating the tin plating step, reducing raw material expenses and production time while maintaining adequate durability for many applications. Economic considerations favor tin-free steel when budget constraints and large-volume production drive the need for lower material costs without compromising essential performance.

Recyclability and Lifecycle Assessment

Tin-plated steel offers enhanced recyclability due to its protective tin coating, which prevents corrosion and maintains material integrity during recycling processes, unlike tin-free steel that is more susceptible to oxidation and degradation. Lifecycle assessments reveal tin-plated steel generally results in a lower environmental impact by extending product lifespan and reducing raw material consumption through improved durability. The tin layer facilitates efficient recycling loops, preserving steel quality and minimizing resource depletion compared to tin-free alternatives.

Advantages and Disadvantages of Each Material

Tin-plated steel offers excellent corrosion resistance and enhanced solderability, making it ideal for food packaging and electrical applications, but it is generally more expensive and prone to tin whisker growth. Tin-free steel, coated with chromium or other metallic layers, provides better weldability and cost-efficiency while maintaining reasonable corrosion protection, though it lacks the superior barrier properties of tin plating. Selecting between tin-plated steel and tin-free steel depends on performance requirements, cost constraints, and susceptibility to environmental factors like moisture and chemical exposure.

Choosing the Right Material for Your Products

Tin-plated steel offers excellent corrosion resistance and a smooth, attractive finish, making it ideal for food packaging and decorative applications where durability and safety are critical. Tin-free steel, coated with alternative protective layers like chromium or organic compounds, provides cost-effective rust protection and is preferred in environments where exposure to moisture is minimal. Selecting between tin-plated and tin-free steel depends on product requirements for longevity, appearance, and exposure conditions, ensuring optimal performance and cost-efficiency.

Tin-plated steel vs Tin-free steel Infographic

materialdif.com

materialdif.com