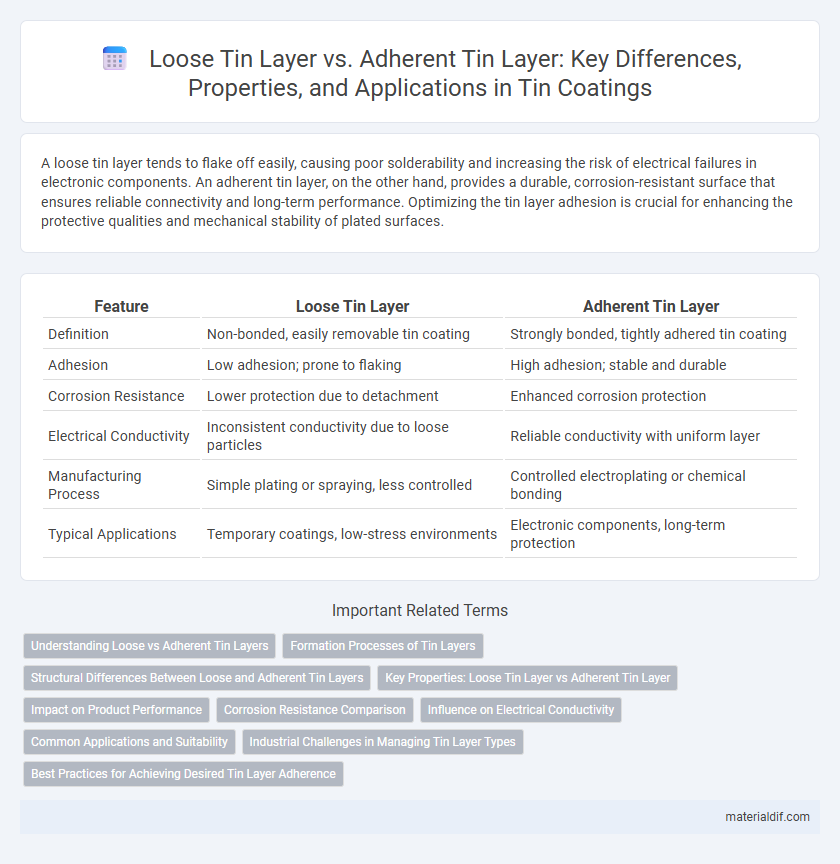

A loose tin layer tends to flake off easily, causing poor solderability and increasing the risk of electrical failures in electronic components. An adherent tin layer, on the other hand, provides a durable, corrosion-resistant surface that ensures reliable connectivity and long-term performance. Optimizing the tin layer adhesion is crucial for enhancing the protective qualities and mechanical stability of plated surfaces.

Table of Comparison

| Feature | Loose Tin Layer | Adherent Tin Layer |

|---|---|---|

| Definition | Non-bonded, easily removable tin coating | Strongly bonded, tightly adhered tin coating |

| Adhesion | Low adhesion; prone to flaking | High adhesion; stable and durable |

| Corrosion Resistance | Lower protection due to detachment | Enhanced corrosion protection |

| Electrical Conductivity | Inconsistent conductivity due to loose particles | Reliable conductivity with uniform layer |

| Manufacturing Process | Simple plating or spraying, less controlled | Controlled electroplating or chemical bonding |

| Typical Applications | Temporary coatings, low-stress environments | Electronic components, long-term protection |

Understanding Loose vs Adherent Tin Layers

Loose tin layers exhibit poor mechanical bonding characterized by easy flaking and low adhesion strength, often resulting from rapid deposition or contamination during plating. Adherent tin layers demonstrate strong metallurgical bonding with the substrate, providing enhanced corrosion resistance and durability critical for reliable electronic soldering applications. Understanding the differences between loose and adherent tin layers is essential for optimizing tin plating processes and ensuring long-term performance of electronic components.

Formation Processes of Tin Layers

Loose tin layers typically form through rapid electroplating or vapor deposition, resulting in weak adhesion due to insufficient atomic bonding with the substrate. In contrast, adherent tin layers develop during controlled thermal diffusion or slow plating processes, promoting strong metallurgical bonds and enhanced surface integrity. The formation processes directly influence mechanical stability, corrosion resistance, and electrical conductivity of the tin coatings.

Structural Differences Between Loose and Adherent Tin Layers

Loose tin layers exhibit a porous and uneven structure with weak intermetallic bonding, leading to lower adhesion and easy detachment under mechanical stress. In contrast, adherent tin layers possess a dense, uniform microstructure characterized by strong metallurgical bonding to the substrate, enhancing corrosion resistance and mechanical durability. These structural differences critically impact the performance of tin coatings in electronic and soldering applications.

Key Properties: Loose Tin Layer vs Adherent Tin Layer

Loose tin layers exhibit poor mechanical stability and are prone to flaking, leading to increased contamination and compromised electrical conductivity in electronic components. In contrast, adherent tin layers offer superior adhesion to substrates, enhancing corrosion resistance and ensuring consistent thermal and electrical performance over time. The key differentiation lies in tin layer integrity, with adherent layers providing durability essential for reliable soldering and long-term device reliability.

Impact on Product Performance

Loose tin layers increase the risk of tin whisker growth, causing short circuits and compromising electronic device reliability. Adherent tin layers provide better mechanical stability and corrosion resistance, enhancing product durability and electrical performance. Selecting an adherent tin layer minimizes failure rates and improves long-term operational stability in sensitive electronic components.

Corrosion Resistance Comparison

A loose tin layer exhibits significantly lower corrosion resistance compared to an adherent tin layer due to its poor mechanical bonding and increased susceptibility to environmental factors such as moisture and oxygen. The adherent tin layer forms a continuous and uniform protective barrier that effectively inhibits the penetration of corrosive agents, thereby enhancing the longevity of metallic substrates. Studies show that adherent tin layers reduce oxidation rates by up to 70%, making them the preferred choice for corrosion protection in electronic and industrial applications.

Influence on Electrical Conductivity

Loose tin layers exhibit poor electrical conductivity due to increased contact resistance and potential for oxidation, which disrupts electron flow. In contrast, adherent tin layers form a stable, uniform coating that maintains low resistance and enhances reliable conductivity in electronic components. The quality of tin adhesion directly influences the performance and longevity of electrical connections.

Common Applications and Suitability

Loose tin layers are commonly used in applications requiring temporary protection against corrosion, such as soldering in electronics, where easy removal is beneficial. Adherent tin layers provide strong, durable corrosion resistance, making them suitable for long-term applications in automotive parts and food packaging. Selecting loose tin is ideal for processes emphasizing reworkability, while adherent tin suits environments demanding sustained surface integrity.

Industrial Challenges in Managing Tin Layer Types

Industrial challenges in managing loose tin layers involve contamination risks and reduced solderability, leading to compromised electrical performance and joint reliability. Adherent tin layers, while offering better mechanical bonding, pose difficulties in controlled thickness uniformity and require precise process parameters to avoid brittle intermetallic compound formation. Effective quality control and advanced coating techniques are critical to balancing the trade-offs between adhesion properties and functional durability in tin-plated components.

Best Practices for Achieving Desired Tin Layer Adherence

Achieving a robust adherent tin layer requires precise control of plating parameters, including bath chemistry, temperature, and current density, to ensure uniform nucleation and growth. Surface preparation techniques such as thorough cleaning and activation are critical to eliminate contaminants and oxide layers that impede tin adhesion. Optimizing these factors minimizes the risk of loose tin layers, enhances mechanical strength, and improves long-term reliability in electronic and industrial applications.

Loose Tin Layer vs Adherent Tin Layer Infographic

materialdif.com

materialdif.com