Tin soldering involves joining metals using a filler metal with a melting point below 450degC, creating a strong, conductive bond ideal for electronic components. Tin brazing, on the other hand, uses a higher temperature filler metal above 450degC, producing a more durable joint suitable for heavy-duty applications and metalwork requiring enhanced mechanical strength. Both methods rely on tin-based alloys but differ significantly in temperature, bond strength, and application scope.

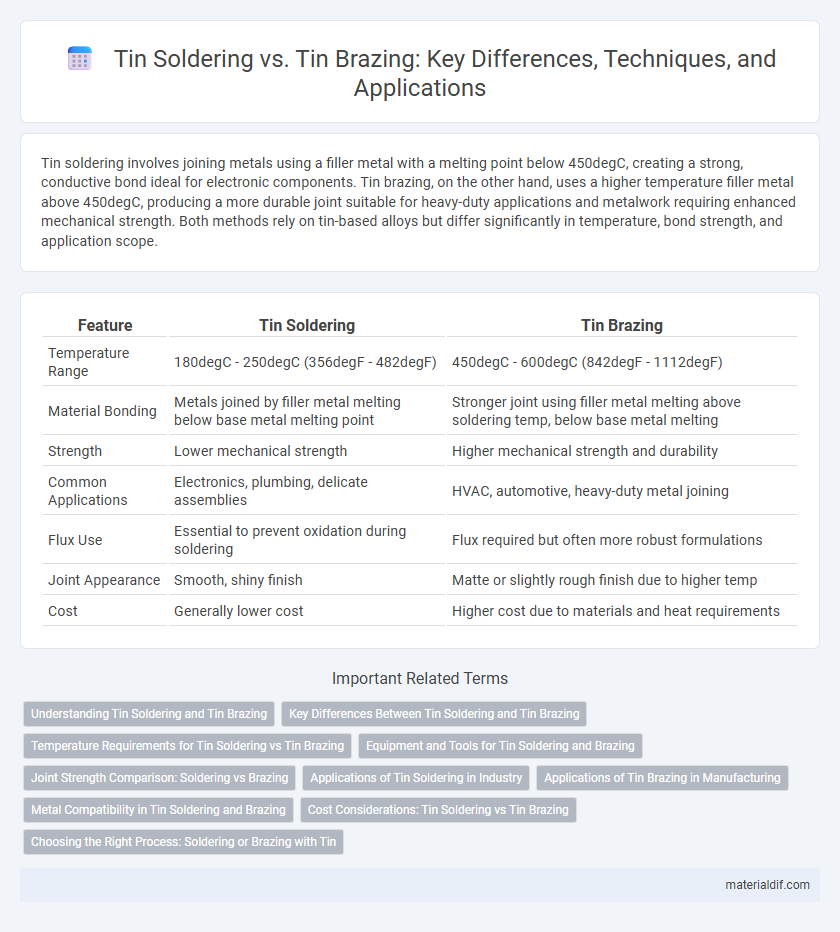

Table of Comparison

| Feature | Tin Soldering | Tin Brazing |

|---|---|---|

| Temperature Range | 180degC - 250degC (356degF - 482degF) | 450degC - 600degC (842degF - 1112degF) |

| Material Bonding | Metals joined by filler metal melting below base metal melting point | Stronger joint using filler metal melting above soldering temp, below base metal melting |

| Strength | Lower mechanical strength | Higher mechanical strength and durability |

| Common Applications | Electronics, plumbing, delicate assemblies | HVAC, automotive, heavy-duty metal joining |

| Flux Use | Essential to prevent oxidation during soldering | Flux required but often more robust formulations |

| Joint Appearance | Smooth, shiny finish | Matte or slightly rough finish due to higher temp |

| Cost | Generally lower cost | Higher cost due to materials and heat requirements |

Understanding Tin Soldering and Tin Brazing

Tin soldering involves joining metals using a filler metal with a melting point typically below 450degC, primarily employing tin-based alloys to create strong, conductive bonds ideal for electronics and delicate components. Tin brazing, on the other hand, uses a filler metal with a melting point above 450degC, often tin-lead or tin-silver alloys, to produce more robust joints suitable for plumbing and heavy-duty applications. Understanding the temperature thresholds, alloy compositions, and intended applications is crucial for selecting the appropriate tin-based joining method for durable and effective metal connections.

Key Differences Between Tin Soldering and Tin Brazing

Tin soldering involves joining metals by melting a tin-based filler metal below 450degC, creating a bond without melting the base metals, ideal for delicate electronic components. Tin brazing uses a higher temperature process above 450degC, where tin alloys form a stronger, more heat-resistant joint by slightly melting the base metals, commonly applied in plumbing and HVAC systems. Key differences include melting temperature, joint strength, and application suitability, with soldering preferred for electrical connections and brazing for structural, load-bearing joints.

Temperature Requirements for Tin Soldering vs Tin Brazing

Tin soldering typically occurs at temperatures below 450degC, allowing for delicate joint formation without damaging heat-sensitive components, while tin brazing requires higher temperatures generally above 450degC, facilitating stronger, metallurgically bonded joints. Soldering melts the filler metal below the base metals' melting points, whereas brazing involves heating the assembly to a point where the filler metal flows and bonds at elevated temperatures. Understanding these temperature thresholds is crucial for selecting an appropriate joining process in electronics and metal fabrication industries.

Equipment and Tools for Tin Soldering and Brazing

Tin soldering requires precise temperature-controlled soldering irons or stations designed for fine electronics work, typically operating between 200degC and 250degC, along with flux applicators and fine-tip soldering tips. Tin brazing demands higher heat sources such as oxy-fuel torches or induction heaters reaching temperatures above 450degC to melt brazing alloys, complemented by heavier-duty clamps and heat-resistant gloves for safety. Both processes utilize fluxes to clean metal surfaces, but brazing equipment is generally more robust to handle elevated temperatures and larger workpieces.

Joint Strength Comparison: Soldering vs Brazing

Tin brazing produces joints with significantly higher strength than tin soldering due to the higher temperatures and metallurgical bonding involved. Soldered joints typically achieve tensile strengths around 20-40 MPa, while brazed joints can reach tensile strengths exceeding 300 MPa. The enhanced joint durability in tin brazing makes it more suitable for structural and high-stress applications compared to the weaker mechanical bonds formed in tin soldering.

Applications of Tin Soldering in Industry

Tin soldering is widely used in the electronics industry for joining electrical components due to its excellent electrical conductivity and low melting point, ensuring reliable connections without damaging sensitive parts. It is essential in circuit board assembly, automotive wiring, and appliance manufacturing, where precision and durability are critical. The process offers strong mechanical bonds and corrosion resistance, making it ideal for mass production and repair applications.

Applications of Tin Brazing in Manufacturing

Tin brazing is widely used in manufacturing for joining dissimilar metals such as copper and steel due to its ability to create strong, corrosion-resistant joints without melting the base metals. It is commonly applied in the production of heat exchangers, automotive components, and electrical assemblies where precise, leak-proof connections are critical. The process enables high-strength bonds suitable for high-temperature and high-pressure environments, offering durability and reliability in industrial applications.

Metal Compatibility in Tin Soldering and Brazing

Tin soldering offers excellent metal compatibility with copper, brass, and nickel alloys due to its lower melting point, reducing the risk of thermal damage to sensitive components. Tin brazing, requiring higher temperatures, is better suited for joining metals like steel, stainless steel, and certain nickel-based alloys where stronger mechanical bonds are essential. The selection between tin soldering and brazing depends on the thermal tolerance and metallurgical properties of the base materials involved in the assembly.

Cost Considerations: Tin Soldering vs Tin Brazing

Tin soldering generally involves lower material costs and simpler equipment compared to tin brazing, making it more cost-effective for small-scale or precision electronic applications. Tin brazing requires higher temperatures and more expensive filler materials but offers stronger joint strength and durability, which can reduce long-term maintenance expenses in industrial settings. Evaluating the total cost involves balancing initial expenses against performance requirements and lifecycle costs in manufacturing or repair projects.

Choosing the Right Process: Soldering or Brazing with Tin

Choosing the right process between tin soldering and tin brazing depends on the required joint strength and temperature tolerance. Tin soldering uses a lower melting point alloy, ideal for delicate electronic components and thin metals, while tin brazing employs higher temperatures and produces stronger, more durable joints suited for plumbing and mechanical assemblies. Understanding the thermal and mechanical requirements of the application ensures optimal performance when selecting between tin soldering and tin brazing.

Tin soldering vs tin brazing Infographic

materialdif.com

materialdif.com