Hot-dipped tinning involves immersing metal parts in molten tin, creating a thick, durable coating that offers superior corrosion resistance and excellent solderability. Electrolytic tinning uses an electric current to deposit a thin, uniform layer of tin, providing precise control over coating thickness and smooth surface finish ideal for delicate electronic components. While hot-dipped tinning excels in heavy-duty protection, electrolytic tinning is preferred for applications requiring fine detail and high purity.

Table of Comparison

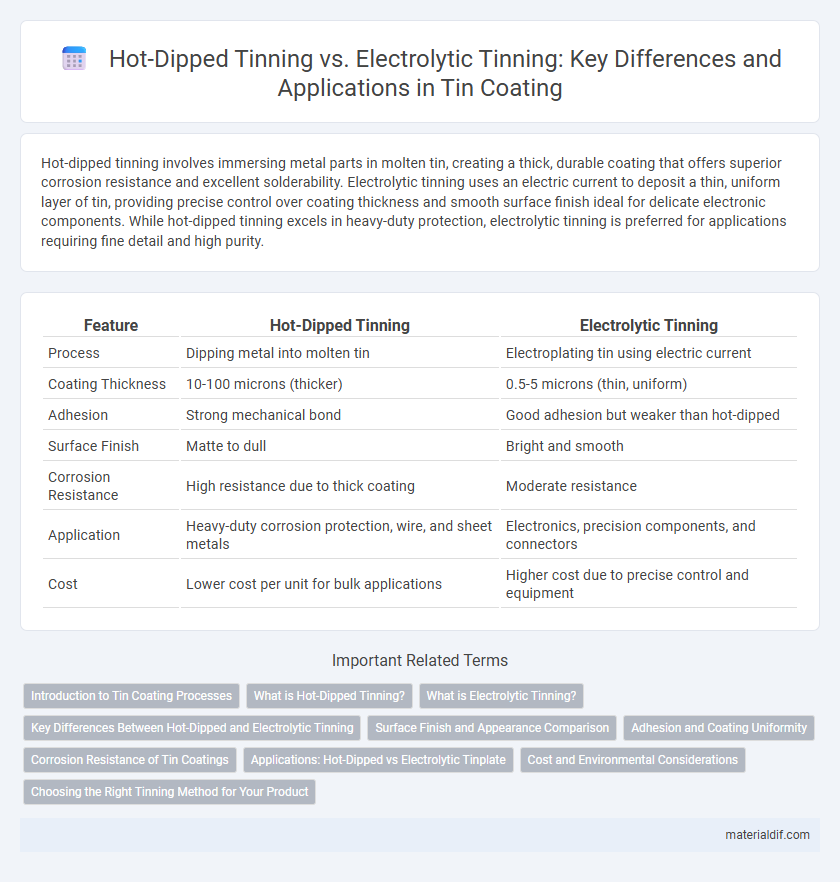

| Feature | Hot-Dipped Tinning | Electrolytic Tinning |

|---|---|---|

| Process | Dipping metal into molten tin | Electroplating tin using electric current |

| Coating Thickness | 10-100 microns (thicker) | 0.5-5 microns (thin, uniform) |

| Adhesion | Strong mechanical bond | Good adhesion but weaker than hot-dipped |

| Surface Finish | Matte to dull | Bright and smooth |

| Corrosion Resistance | High resistance due to thick coating | Moderate resistance |

| Application | Heavy-duty corrosion protection, wire, and sheet metals | Electronics, precision components, and connectors |

| Cost | Lower cost per unit for bulk applications | Higher cost due to precise control and equipment |

Introduction to Tin Coating Processes

Hot-dipped tinning involves immersing metal substrates in molten tin, creating a thick, uniform coating that offers excellent corrosion resistance and solderability. Electrolytic tinning uses an electric current to deposit a thin, controlled layer of tin onto the substrate, ensuring precise coating thickness and smooth finish. Both processes are essential for enhancing the durability and conductive properties of metal components in electronics and packaging industries.

What is Hot-Dipped Tinning?

Hot-dipped tinning is a process where metal parts are immersed in molten tin to create a thick, durable coating that enhances corrosion resistance and solderability. This method produces a robust, uniform layer of tin, making it ideal for protecting steel and iron components in harsh environments. Compared to electrolytic tinning, hot-dipped tinning offers superior mechanical adhesion and long-lasting protection against oxidation.

What is Electrolytic Tinning?

Electrolytic tinning is a metal plating process where a thin layer of tin is deposited onto a metal substrate using an electric current in an electrolytic bath containing tin ions. This method offers precise control over the thickness and uniformity of the tin coating, enhancing corrosion resistance and solderability on components like steel strips and copper wires. Unlike hot-dipped tinning, electrolytic tinning produces a smoother, more refined surface finish, ideal for electronic and industrial applications requiring high-quality plating standards.

Key Differences Between Hot-Dipped and Electrolytic Tinning

Hot-dipped tinning involves immersing the metal substrate in molten tin, creating a thicker, more uniform coating typically ranging from 1.5 to 20 microns, which enhances corrosion resistance and mechanical durability. Electrolytic tinning uses an electrochemical process to deposit a thinner, more controlled tin layer, generally between 0.5 to 2 microns, providing superior surface smoothness and precision for electronic components. Key differences include coating thickness, application method, corrosion protection, and suitability for various substrates and industrial uses.

Surface Finish and Appearance Comparison

Hot-dipped tinning produces a thicker, more uniform tin layer with a slightly rougher surface finish, enhancing corrosion resistance and durability. Electrolytic tinning creates a thinner, more controlled tin coating with a smoother, shinier appearance suitable for fine electronic components. Surface finish from electrolytic tinning typically offers superior brightness and precision, while hot-dipped tinning provides a robust, matte texture optimal for heavy-duty applications.

Adhesion and Coating Uniformity

Hot-dipped tinning offers superior adhesion due to the molten tin's metallurgical bond with the substrate, resulting in a robust and durable coating. Electrolytic tinning provides excellent coating uniformity, allowing precise thickness control and consistent coverage even on complex geometries. The choice between hot-dipped and electrolytic tinning depends on the specific application requirements for adhesion strength and uniformity of the tin layer.

Corrosion Resistance of Tin Coatings

Hot-dipped tinning produces a thicker, more uniform tin coating that significantly enhances corrosion resistance by creating a robust physical barrier against environmental factors. Electrolytic tinning offers a thinner, more controlled layer, which provides adequate corrosion protection but is generally less durable under aggressive conditions. The choice between these methods depends on the desired balance between coating thickness, corrosion resistance, and cost-effectiveness for specific applications.

Applications: Hot-Dipped vs Electrolytic Tinplate

Hot-dipped tinning creates a thick, corrosion-resistant coating ideal for food and beverage cans requiring robust protection against oxidation and moisture. Electrolytic tinning produces a thinner, more uniform layer suited for electrical components, electronics packaging, and automotive parts where precision and conductivity are critical. The choice between hot-dipped and electrolytic tinplate depends on the application's need for mechanical durability versus surface finish and electrical performance.

Cost and Environmental Considerations

Hot-dipped tinning generally incurs higher initial equipment and energy costs compared to electrolytic tinning, but it offers superior corrosion resistance and thickness uniformity, reducing long-term maintenance expenses. Electrolytic tinning operates at lower temperatures with less energy consumption, producing less hazardous waste and enabling easier recycling of process solutions, which benefits environmental sustainability. Both methods require careful management of chemical effluents, yet electrolytic tinning typically results in lower environmental impact due to reduced chemical usage and more controllable waste streams.

Choosing the Right Tinning Method for Your Product

Selecting the appropriate tinning method depends on the desired coating thickness and corrosion resistance; hot-dipped tinning provides a thicker, more durable layer ideal for heavy-duty applications, while electrolytic tinning offers precise, uniform coatings suited for delicate electronics. Consider factors such as thermal stability, surface finish, and cost efficiency to match the tinning process with product requirements. Evaluating these parameters ensures optimal performance, longevity, and aesthetic quality of the tin-coated components.

Hot-dipped tinning vs Electrolytic tinning Infographic

materialdif.com

materialdif.com