Recycling tin requires significantly less energy than producing virgin tin, resulting in reduced greenhouse gas emissions and lower environmental impact. Using recycled tin helps conserve finite natural resources by decreasing the demand for new mining activities. Furthermore, recycled tin maintains the same quality and functionality, making it an efficient and sustainable choice for manufacturers.

Table of Comparison

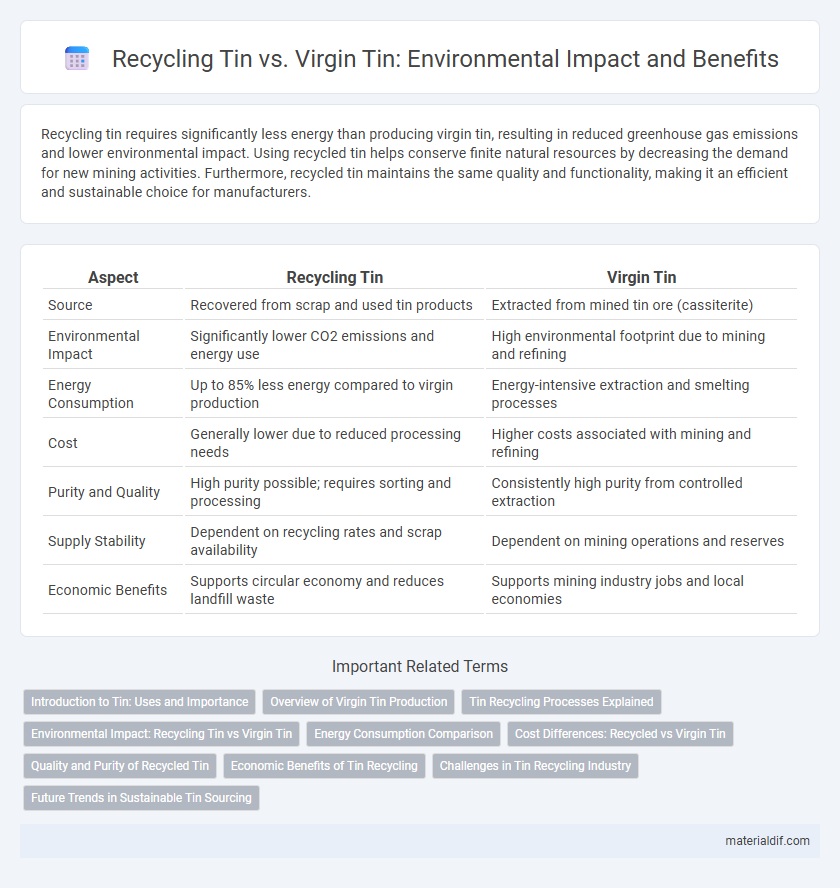

| Aspect | Recycling Tin | Virgin Tin |

|---|---|---|

| Source | Recovered from scrap and used tin products | Extracted from mined tin ore (cassiterite) |

| Environmental Impact | Significantly lower CO2 emissions and energy use | High environmental footprint due to mining and refining |

| Energy Consumption | Up to 85% less energy compared to virgin production | Energy-intensive extraction and smelting processes |

| Cost | Generally lower due to reduced processing needs | Higher costs associated with mining and refining |

| Purity and Quality | High purity possible; requires sorting and processing | Consistently high purity from controlled extraction |

| Supply Stability | Dependent on recycling rates and scrap availability | Dependent on mining operations and reserves |

| Economic Benefits | Supports circular economy and reduces landfill waste | Supports mining industry jobs and local economies |

Introduction to Tin: Uses and Importance

Tin, a versatile metal primarily used in soldering, plating, and alloys like bronze and pewter, plays a crucial role in electronics, packaging, and construction industries. Recycling tin conserves natural resources and reduces environmental impact, while virgin tin extraction is energy-intensive and involves mining challenges such as habitat disruption. The growing demand for sustainable practices highlights the significance of prioritizing recycled tin to maintain supply and minimize the ecological footprint.

Overview of Virgin Tin Production

Virgin tin production involves extracting tin ore primarily from cassiterite deposits through mining operations, followed by refining processes such as smelting and electrolytic refining to obtain high-purity tin metal. This process requires significant energy consumption and results in environmental impacts due to land disturbance and emissions from mining and smelting activities. In comparison, recycling tin reduces the demand for mining, lowers energy use by up to 60%, and minimizes ecological damage, making virgin tin production less sustainable in terms of resource efficiency and environmental footprint.

Tin Recycling Processes Explained

Tin recycling involves collecting scrap tin from electronic waste, solder materials, and tin plating residues, which is then refined through processes such as melting, chemical treatment, and electrolysis to restore high-purity tin. Compared to virgin tin extracted from cassiterite ore via roasting and smelting, recycled tin significantly reduces environmental impact and energy consumption. Advanced tin recycling techniques ensure the recovery of up to 95% of tin content, making it a sustainable alternative that supports circular economy principles in the metals industry.

Environmental Impact: Recycling Tin vs Virgin Tin

Recycling tin significantly reduces environmental impact by lowering energy consumption and minimizing mining-related habitat destruction compared to virgin tin extraction. The recycling process cuts greenhouse gas emissions by up to 60% and decreases the release of toxic pollutants into soil and water. Utilizing recycled tin supports sustainable resource management and reduces the dependence on finite natural reserves.

Energy Consumption Comparison

Recycling tin consumes up to 60% less energy compared to producing virgin tin from primary ore extraction, significantly reducing carbon emissions. The energy-intensive process of mining and smelting virgin tin requires approximately 55-60 MJ/kg, while recycled tin production uses around 20-25 MJ/kg. Implementing recycled tin in manufacturing lowers overall energy demand and supports sustainable metal resource management.

Cost Differences: Recycled vs Virgin Tin

Recycling tin significantly reduces costs compared to virgin tin by lowering raw material expenses and energy consumption during production. Virgin tin extraction requires extensive mining and smelting processes, driving up overall prices due to labor, equipment, and environmental compliance costs. Using recycled tin not only supports sustainability but also offers economic benefits through decreased material procurement and processing expenditures.

Quality and Purity of Recycled Tin

Recycled tin maintains a high level of quality and purity, often reaching up to 99.9% purity, comparable to virgin tin used in industrial applications. Advanced refining techniques remove contaminants, ensuring recycled tin meets stringent standards for electronics, soldering, and plating. Utilizing recycled tin reduces environmental impact while providing a reliable, cost-effective material without compromising performance.

Economic Benefits of Tin Recycling

Recycling tin significantly reduces production costs by lowering energy consumption by up to 60% compared to extracting virgin tin from ores. Recycled tin circumvents expensive mining and refining processes, enhancing profitability and stabilizing supply chains affected by fluctuating raw material prices. The economic benefits include reduced dependency on volatile tin markets and decreased environmental compliance costs, leading to sustainable financial gains for manufacturers.

Challenges in Tin Recycling Industry

Recycling tin faces significant challenges due to contamination with other metals and impurities, which complicates the extraction and purification process. The limited availability of efficient, cost-effective separation technologies hinders the scalability of tin recycling compared to the extraction of virgin tin from primary ore sources. Environmental concerns and inconsistent recycling streams also impact the quality and supply stability of recycled tin in the market.

Future Trends in Sustainable Tin Sourcing

Recycling tin significantly reduces environmental impact by lowering energy consumption and minimizing mining waste compared to virgin tin extraction. Future trends emphasize the integration of advanced collection technologies and closed-loop recycling systems to enhance tin recovery rates and resource efficiency. Increasing demand for sustainable electronics and renewable energy sectors will drive innovation in responsible tin sourcing and circular economy practices.

Recycling Tin vs Virgin Tin Infographic

materialdif.com

materialdif.com