Stannous oxide (SnO) and stannic oxide (SnO2) are two distinct tin compounds with different oxidation states and applications. Stannous oxide contains tin in the +2 oxidation state and is often used as a reducing agent and in ceramics, while stannic oxide features tin in the +4 state and serves as a key material in gas sensors, transparent conducting films, and catalysis. Understanding the differences in their chemical properties and uses is essential for selecting the appropriate oxide in industrial and technological processes.

Table of Comparison

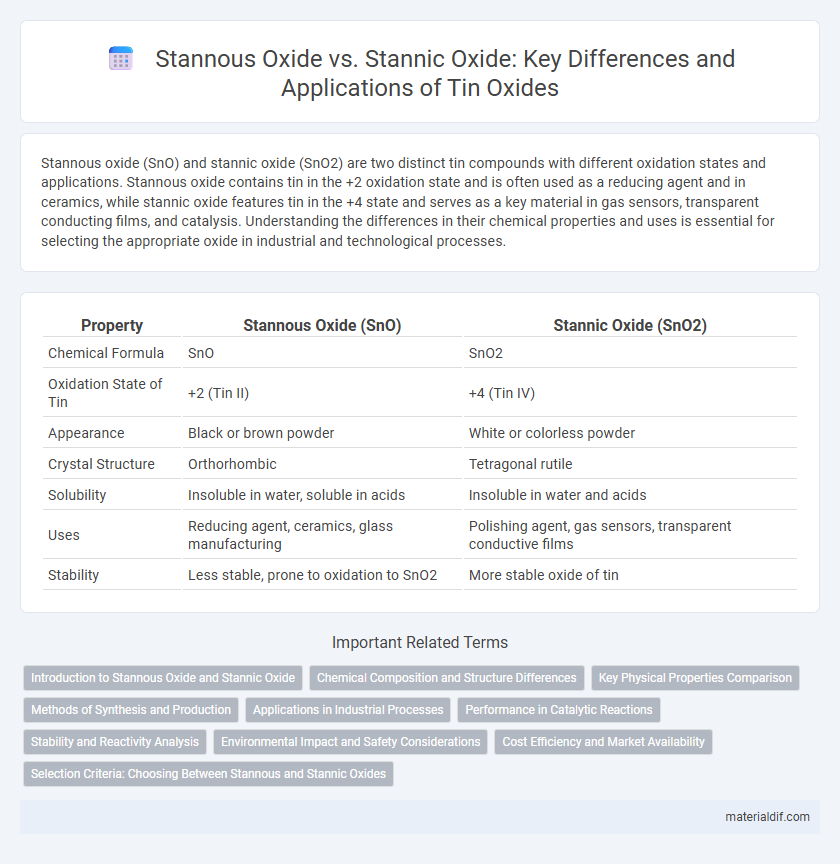

| Property | Stannous Oxide (SnO) | Stannic Oxide (SnO2) |

|---|---|---|

| Chemical Formula | SnO | SnO2 |

| Oxidation State of Tin | +2 (Tin II) | +4 (Tin IV) |

| Appearance | Black or brown powder | White or colorless powder |

| Crystal Structure | Orthorhombic | Tetragonal rutile |

| Solubility | Insoluble in water, soluble in acids | Insoluble in water and acids |

| Uses | Reducing agent, ceramics, glass manufacturing | Polishing agent, gas sensors, transparent conductive films |

| Stability | Less stable, prone to oxidation to SnO2 | More stable oxide of tin |

Introduction to Stannous Oxide and Stannic Oxide

Stannous oxide (SnO) and stannic oxide (SnO2) are two primary oxides of tin, distinguished by their oxidation states; SnO contains tin in the +2 state while SnO2 features tin in the +4 state. Stannous oxide is typically used as a reducing agent and in ceramic glazes, exhibiting a black or gray powder form, whereas stannic oxide, also known as tin dioxide, appears as a white or colorless solid primarily utilized as a catalyst and in gas sensors. The chemical and physical properties of these oxides reflect their distinct electronic structures and reactivities, crucial for applications in electronics, coatings, and material science.

Chemical Composition and Structure Differences

Stannous oxide (SnO) consists of tin in the +2 oxidation state, featuring a tetragonal crystal structure with one tin atom bonded to one oxygen atom. Stannic oxide (SnO2) contains tin in the +4 oxidation state and adopts a rutile-type tetragonal crystal structure, where each tin atom is coordinated to six oxygen atoms in an octahedral arrangement. The difference in oxidation states leads to distinct electronic properties, with SnO being a p-type semiconductor and SnO2 an n-type semiconductor.

Key Physical Properties Comparison

Stannous oxide (SnO) has a tetragonal crystal structure with a melting point around 1080degC, exhibiting p-type semiconducting behavior and a dark grey to black color. Stannic oxide (SnO2) features a rutile tetragonal structure, a higher melting point near 1630degC, and is typically a white, n-type semiconductor with excellent chemical stability. The differences in crystal form, melting point, electrical conductivity type, and color are key physical property distinctions crucial for applications in sensors and catalysis.

Methods of Synthesis and Production

Stannous oxide (SnO) is commonly synthesized through the controlled partial oxidation of tin metal or thermal decomposition of tin(II) compounds, often under reducing atmospheres to maintain the +2 oxidation state. In contrast, stannic oxide (SnO2) is typically produced via direct oxidation of tin or chemical precipitation methods involving tin(IV) salts followed by calcination, ensuring a stable +4 oxidation state. Industrial production of SnO2 also frequently employs flame hydrolysis or spray pyrolysis techniques to achieve high-purity, nanostructured powders essential for applications in sensors and catalysis.

Applications in Industrial Processes

Stannous oxide (SnO) is widely used as a reducing agent and in ceramic glazes for its ability to impart color and conductivity. Stannic oxide (SnO2) serves as a crucial material in gas sensors, transparent conductive coatings, and as a catalyst in industrial oxidation processes. Industrial applications leverage SnO for its semiconductor properties in anode production, while SnO2 is integral in energy storage devices and environmental catalysis.

Performance in Catalytic Reactions

Stannous oxide (SnO) exhibits higher catalytic activity in reduction reactions due to its lower oxidation state, facilitating electron transfer processes more efficiently. Stannic oxide (SnO2) demonstrates superior stability and performance in oxidation reactions, benefiting from its robust tetravalent tin structure and high surface area. The choice between SnO and SnO2 significantly impacts catalytic efficiency, selectivity, and durability depending on the specific reaction environment.

Stability and Reactivity Analysis

Stannous oxide (SnO) exhibits lower stability due to its +2 oxidation state, making it more reactive and prone to oxidation compared to stannic oxide (SnO2), which is highly stable in the +4 state. Stannic oxide's robust crystal lattice and inert nature contribute to its widespread use in pigments and gas sensors. The comparative reactivity of SnO facilitates applications in reducing environments, while SnO2 remains favored for corrosion resistance and catalytic properties.

Environmental Impact and Safety Considerations

Stannous oxide (SnO) is less stable and more prone to oxidation, posing moderate environmental risks due to its potential release of tin ions, which can affect aquatic life through bioaccumulation. Stannic oxide (SnO2) is chemically stable, exhibits lower toxicity, and is widely used as a non-toxic pigment and catalyst, making it environmentally safer with minimal hazardous waste concerns. Both oxides require proper handling to prevent inhalation of fine powders, but SnO2's inert nature results in fewer safety challenges in industrial applications.

Cost Efficiency and Market Availability

Stannous oxide (SnO) offers cost efficiency due to its lower production expenses and widespread availability in various industrial applications, making it favorable for large-scale manufacturing processes. Stannic oxide (SnO2), although more expensive, provides superior stability and is extensively used in advanced electronics and gas sensor markets where performance justifies higher costs. Market availability of stannous oxide is robust in bulk chemical suppliers, whereas stannic oxide's demand in high-tech sectors results in a more specialized but steadily growing supply chain.

Selection Criteria: Choosing Between Stannous and Stannic Oxides

Stannous oxide (SnO) is preferred for applications requiring reducing properties, such as in gas sensors and as a semiconductor in electronic devices, due to its +2 oxidation state and relatively higher conductivity. Stannic oxide (SnO2) is chosen for its stability and strong oxidizing characteristics, making it ideal for catalytic converters, transparent conductive coatings, and gas sensing at elevated temperatures. Selection between stannous and stannic oxides depends on factors like required oxidation state, thermal stability, electrical conductivity, and environmental conditions of the intended application.

Stannous oxide vs Stannic oxide Infographic

materialdif.com

materialdif.com