Solderable tin offers excellent adhesion and creates strong, reliable joints essential for electronic and metal assembly applications. Non-solderable tin, often used for decorative or corrosion-resistant purposes, lacks the ability to form durable solder bonds. Choosing solderable tin ensures optimal electrical connectivity and mechanical stability in manufacturing processes.

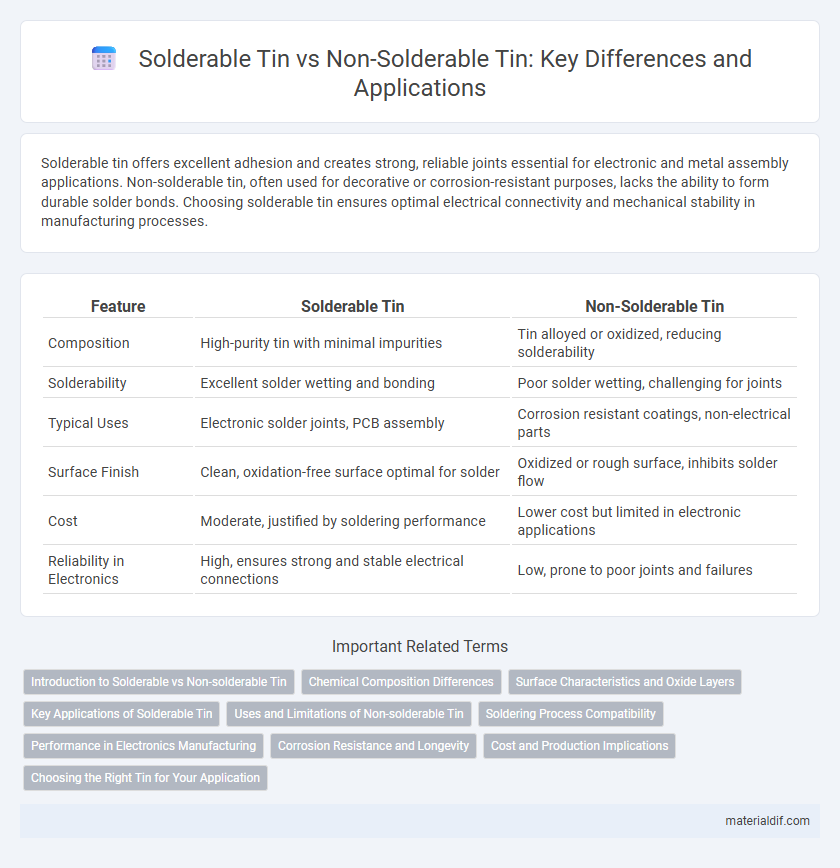

Table of Comparison

| Feature | Solderable Tin | Non-Solderable Tin |

|---|---|---|

| Composition | High-purity tin with minimal impurities | Tin alloyed or oxidized, reducing solderability |

| Solderability | Excellent solder wetting and bonding | Poor solder wetting, challenging for joints |

| Typical Uses | Electronic solder joints, PCB assembly | Corrosion resistant coatings, non-electrical parts |

| Surface Finish | Clean, oxidation-free surface optimal for solder | Oxidized or rough surface, inhibits solder flow |

| Cost | Moderate, justified by soldering performance | Lower cost but limited in electronic applications |

| Reliability in Electronics | High, ensures strong and stable electrical connections | Low, prone to poor joints and failures |

Introduction to Solderable vs Non-solderable Tin

Solderable tin possesses a clean, oxide-free surface that promotes excellent wettability, enabling strong mechanical and electrical connections in electronic assembly. Non-solderable tin contains surface contaminants or a thick oxide layer, impeding solder adhesion and resulting in weak or unreliable joints. Understanding the differences in surface chemistry and preparation is crucial for selecting the appropriate tin type for soldering applications.

Chemical Composition Differences

Solderable tin typically contains a high purity of tin (Sn) often exceeding 99.8%, sometimes alloyed with small amounts of silver (Ag) or copper (Cu) to enhance solderability and mechanical strength. Non-solderable tin, in contrast, may include higher levels of impurities such as lead (Pb), bismuth (Bi), or antimony (Sb), which adversely affect its wetting properties and prevent effective solder joint formation. These differences in chemical composition directly influence the metallurgical compatibility and performance during the soldering process.

Surface Characteristics and Oxide Layers

Solderable tin features a smooth, clean surface with minimal oxide formation, enabling strong metallurgical bonding during soldering processes. Non-solderable tin tends to develop thicker, rough oxide layers that inhibit wetting by solder, leading to poor joint quality. The surface characteristics and oxide layer thickness directly influence solderability, with reduced oxides enhancing electrical conductivity and mechanical reliability.

Key Applications of Solderable Tin

Solderable tin is widely used in electronics manufacturing for creating reliable electrical connections due to its excellent wettability and corrosion resistance. Key applications include printed circuit boards (PCBs), surface-mount devices (SMDs), and connectors where strong, conductive joints are essential. Its compatibility with various solder alloys ensures durability in consumer electronics, automotive components, and aerospace systems.

Uses and Limitations of Non-solderable Tin

Non-solderable tin, often used as a protective coating on electronic components, prevents corrosion and provides electrical insulation but cannot be joined using traditional soldering techniques. Its primary limitation lies in the inability to form reliable mechanical and electrical connections, restricting its application to non-joinable surfaces or as a barrier layer. Industries requiring durable, non-conductive coatings utilize non-solderable tin for surface protection rather than circuit assembly.

Soldering Process Compatibility

Solderable tin offers excellent wettability and adhesion during the soldering process, ensuring strong mechanical and electrical connections. Non-solderable tin lacks this compatibility, often resulting in poor bond formation and increased risk of joint failure. Selecting solderable tin is critical for reliable and efficient soldering in electronic assemblies.

Performance in Electronics Manufacturing

Solderable tin offers superior electrical conductivity and strong adhesion properties essential for reliable electronic connections, enhancing circuit board performance and durability. Non-solderable tin lacks the necessary fluxing agents and surface characteristics, leading to poor wettability and weak mechanical bonds during soldering processes. In electronics manufacturing, choosing solderable tin minimizes defects and improves overall device reliability by ensuring consistent solder joint integrity.

Corrosion Resistance and Longevity

Solderable tin offers superior corrosion resistance due to its ability to form strong, stable intermetallic bonds with other metals, which enhances the longevity of electronic components by preventing oxidation and degradation. Non-solderable tin lacks this bonding capability, making it more susceptible to corrosion and reducing the lifespan of metal surfaces in harsh environments. The enhanced durability of solderable tin makes it the preferred choice for applications requiring long-term reliability and resistance to environmental factors.

Cost and Production Implications

Solderable tin, commonly used in electronics manufacturing, offers cost-efficiency by enabling faster assembly lines due to its excellent wetting properties and low melting point, reducing production time and energy consumption. Non-solderable tin, often found in applications requiring corrosion resistance or mechanical strength, incurs higher costs because of additional processing steps and specialized handling during manufacturing. Choosing solderable tin generally lowers overall production expenses by minimizing rework and improving throughput, while non-solderable tin escalates material and labor costs due to its complex application requirements.

Choosing the Right Tin for Your Application

Choosing the right tin for your application depends on its solderability, with solderable tin offering excellent wetting properties for reliable joints in electronics manufacturing, while non-solderable tin is typically used in coatings and plating where soldering is not required. Solderable tin alloys often include small amounts of lead or silver to enhance solder joint strength and minimize whisker growth, whereas non-solderable tin provides corrosion resistance without compatibility for soldering processes. Evaluating the specific requirements of mechanical strength, conductivity, and environmental exposure ensures optimal selection between solderable and non-solderable tin in industrial applications.

Solderable Tin vs Non-solderable Tin Infographic

materialdif.com

materialdif.com