Reflowed tin offers improved solder joint reliability by ensuring uniform melting and better adhesion on electronic components, reducing defects such as voids and cracks. Non-reflowed tin, while easier to apply, may lead to inconsistent solder coverage and weaker mechanical strength, increasing the risk of component failure. Choosing reflowed tin enhances circuit board performance and longevity in demanding applications.

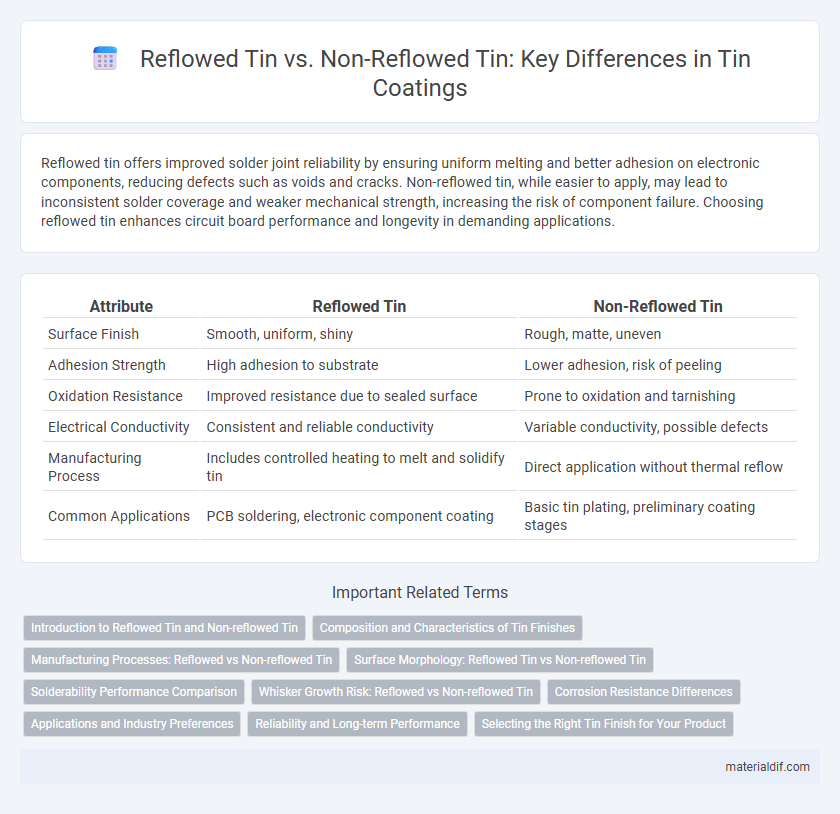

Table of Comparison

| Attribute | Reflowed Tin | Non-Reflowed Tin |

|---|---|---|

| Surface Finish | Smooth, uniform, shiny | Rough, matte, uneven |

| Adhesion Strength | High adhesion to substrate | Lower adhesion, risk of peeling |

| Oxidation Resistance | Improved resistance due to sealed surface | Prone to oxidation and tarnishing |

| Electrical Conductivity | Consistent and reliable conductivity | Variable conductivity, possible defects |

| Manufacturing Process | Includes controlled heating to melt and solidify tin | Direct application without thermal reflow |

| Common Applications | PCB soldering, electronic component coating | Basic tin plating, preliminary coating stages |

Introduction to Reflowed Tin and Non-reflowed Tin

Reflowed tin refers to tin that has undergone a controlled melting and solidification process to improve solder joint quality in electronics manufacturing. Non-reflowed tin is raw or untreated tin that has not experienced this thermal cycle, often exhibiting different mechanical and chemical properties. Understanding the distinction is crucial for optimizing soldering performance and ensuring reliable electronic connections.

Composition and Characteristics of Tin Finishes

Reflowed tin finishes exhibit a uniform, smooth surface due to the melting and solidification process that enhances adhesion and reduces surface oxides, improving solderability. Non-reflowed tin maintains its original plating composition, often leading to a rougher texture with increased risks of whisker growth and poor solder joint reliability. The reflow process alters the microstructure by promoting a more homogeneous intermetallic layer, optimizing electrical conductivity and corrosion resistance compared to untreated tin finishes.

Manufacturing Processes: Reflowed vs Non-reflowed Tin

Reflowed tin undergoes a controlled heating process causing the solder to melt and solidify, which enhances joint reliability and electrical conductivity in electronic manufacturing. Non-reflowed tin remains in its original form without melting, often resulting in weaker mechanical bonds and higher resistance. The choice between reflowed and non-reflowed tin significantly impacts solder joint quality, thermal stability, and overall device performance during PCB assembly.

Surface Morphology: Reflowed Tin vs Non-reflowed Tin

Reflowed tin exhibits a smooth, uniformly crystalline surface morphology due to the controlled melting and solidification process, which enhances solder joint reliability. Non-reflowed tin displays a rougher, irregular surface with distinct grain boundaries and potential oxide inclusions, leading to weaker mechanical properties. The improved wettability and microstructural homogeneity in reflowed tin significantly reduce the likelihood of void formation and intermetallic compound defects.

Solderability Performance Comparison

Reflowed tin exhibits superior solderability performance compared to non-reflowed tin due to its uniform surface morphology and enhanced oxide layer reduction, which facilitate better wetting during soldering. Non-reflowed tin often presents irregular surface oxides and increased roughness, leading to inconsistent solder joint formation and potential cold solder issues. These factors make reflowed tin preferable for high-reliability electronic assembly where consistent solder joint integrity is critical.

Whisker Growth Risk: Reflowed vs Non-reflowed Tin

Reflowed tin undergoes a melting process during soldering, which significantly reduces internal stresses and minimizes whisker growth risk by allowing the tin atoms to redistribute uniformly. Non-reflowed tin retains residual stresses from deposition, increasing the likelihood of whisker formation due to crystalline stress accumulation. Studies indicate that reflowed tin surfaces exhibit markedly lower whisker density and length compared to non-reflowed tin coatings.

Corrosion Resistance Differences

Reflowed tin exhibits enhanced corrosion resistance due to the formation of a uniform, dense intermetallic layer that protects the underlying metal from oxidation and environmental exposure. Non-reflowed tin coatings tend to have uneven surfaces and microscopic voids, which act as initiation sites for corrosion, particularly in humid or acidic conditions. Optimizing reflow parameters reduces defects and improves long-term reliability by minimizing galvanic corrosion and tin whisker growth.

Applications and Industry Preferences

Reflowed tin is primarily used in electronics manufacturing for soldering components onto printed circuit boards (PCBs) due to its excellent wetting properties and strong mechanical bonds. Non-reflowed tin finds applications in coating and plating industries where corrosion resistance is essential but soldering is not required, such as in food packaging and automotive parts. Industry preferences favor reflowed tin in high-reliability sectors like aerospace and consumer electronics, while non-reflowed tin remains dominant in traditional metal finishing applications.

Reliability and Long-term Performance

Reflowed tin forms a uniform, metallurgically bonded surface that significantly improves solder joint reliability by reducing voids and enhancing mechanical strength. Non-reflowed tin coatings often suffer from higher susceptibility to oxidation and whisker growth, leading to compromised long-term electrical performance and potential failure. Utilizing reflowed tin surfaces ensures consistent electrical conductivity and resistance to thermal cycling, critical for durable electronic assemblies.

Selecting the Right Tin Finish for Your Product

Selecting the right tin finish involves comparing reflowed tin and non-reflowed tin based on corrosion resistance, solderability, and surface smoothness. Reflowed tin offers a uniform, smooth surface with enhanced solderability and better protection against oxidation, making it ideal for electronic components requiring reliable connections. Non-reflowed tin, while cost-effective, may have uneven coatings and less durability, suitable for applications where high solderability is not critical.

Reflowed Tin vs Non-reflowed Tin Infographic

materialdif.com

materialdif.com