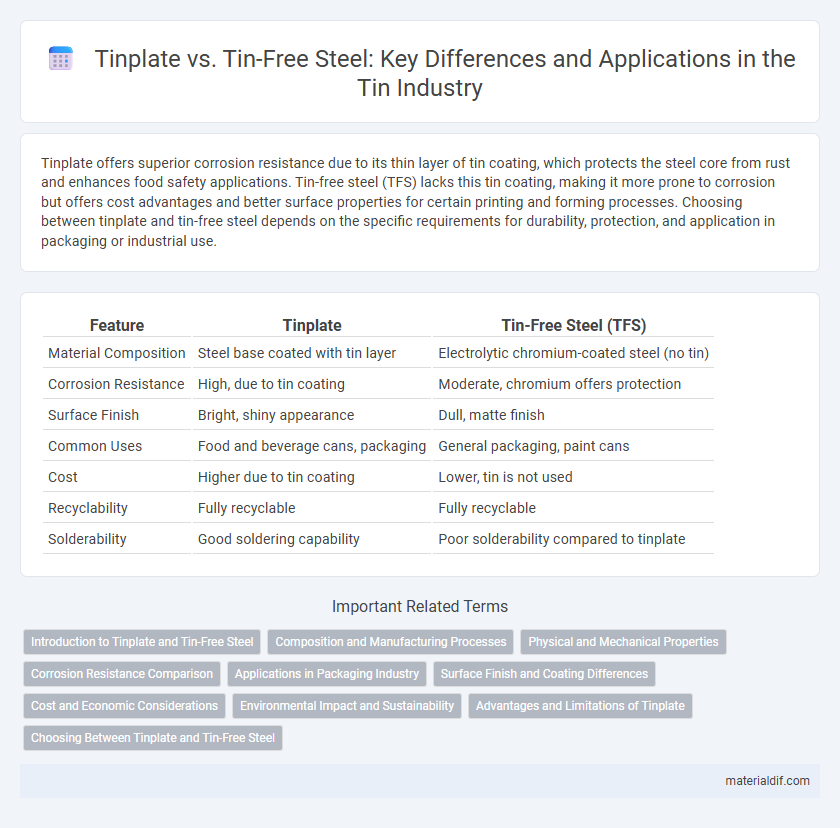

Tinplate offers superior corrosion resistance due to its thin layer of tin coating, which protects the steel core from rust and enhances food safety applications. Tin-free steel (TFS) lacks this tin coating, making it more prone to corrosion but offers cost advantages and better surface properties for certain printing and forming processes. Choosing between tinplate and tin-free steel depends on the specific requirements for durability, protection, and application in packaging or industrial use.

Table of Comparison

| Feature | Tinplate | Tin-Free Steel (TFS) |

|---|---|---|

| Material Composition | Steel base coated with tin layer | Electrolytic chromium-coated steel (no tin) |

| Corrosion Resistance | High, due to tin coating | Moderate, chromium offers protection |

| Surface Finish | Bright, shiny appearance | Dull, matte finish |

| Common Uses | Food and beverage cans, packaging | General packaging, paint cans |

| Cost | Higher due to tin coating | Lower, tin is not used |

| Recyclability | Fully recyclable | Fully recyclable |

| Solderability | Good soldering capability | Poor solderability compared to tinplate |

Introduction to Tinplate and Tin-Free Steel

Tinplate is steel sheet coated with a thin layer of tin, offering excellent corrosion resistance and solderability, commonly used in food packaging and aerosol cans. Tin-free steel (TFS) is produced by applying a chromium-based coating instead of tin, providing good corrosion resistance and weldability while avoiding tin contamination issues. Both materials serve critical roles in packaging and industrial applications, with tinplate favored for direct food contact and TFS preferred where higher mechanical strength and chemical resistance are needed.

Composition and Manufacturing Processes

Tinplate consists of thin steel sheets coated with a layer of tin through electroplating or hot-dip processes, enhancing corrosion resistance and solderability. Tin-free steel (TFS) is produced by electrocoating or chromating bare steel sheets, relying on organic coatings or chromium passivation rather than tin for corrosion protection. The manufacturing of tinplate involves precise tin bath control and cleaning steps, whereas tin-free steel emphasizes advanced surface treatments and coating uniformity to ensure durability without the use of tin.

Physical and Mechanical Properties

Tinplate exhibits excellent corrosion resistance and a smooth, glossy surface due to its thin tin coating, enhancing its suitability for food and beverage packaging. Tin-free steel (TFS) relies on phosphate or chromate coatings, offering superior strength and reduced weight, which improves its formability and mechanical durability. Both materials provide distinctive physical and mechanical properties tailored for specific industrial applications, with tinplate favoring corrosion protection and TFS emphasizing structural performance.

Corrosion Resistance Comparison

Tinplate offers superior corrosion resistance compared to tin-free steel due to its thin tin coating that prevents rust and enhances durability in packaging applications. Tin-free steel relies on a chromium-based passivation layer, which provides adequate corrosion protection but is generally less effective against prolonged moisture exposure. As a result, tinplate remains the preferred choice for applications requiring enhanced corrosion resistance, such as food and beverage cans.

Applications in Packaging Industry

Tinplate is commonly used in the packaging industry for food and beverage cans due to its excellent corrosion resistance and ability to preserve product quality. Tin-free steel (TFS) offers a more cost-effective and environmentally friendly alternative with superior paint adhesion, making it ideal for packaging requiring decorative finishes and corrosion protection. Both materials play crucial roles in packaging, with tinplate favored for direct food contact and TFS preferred for outer packaging layers.

Surface Finish and Coating Differences

Tinplate features a smooth, bright surface finish achieved through electroplating with a thin layer of tin, which provides excellent corrosion resistance and food safety for packaging applications. Tin-free steel (TFS) relies on a chromium or chromium oxide coating that offers a matte finish and enhanced resistance to scratching and high temperatures compared to tinplate. Both materials differ significantly in surface texture and protective coatings, influencing their suitability for various industrial and food packaging uses.

Cost and Economic Considerations

Tinplate offers corrosion resistance with a relatively higher initial cost due to the tin coating process, making it suitable for food packaging where contamination prevention is critical. Tin-free steel (TFS) reduces expenses by eliminating tin plating, relying instead on chromium or chromium oxide coatings, which lowers production costs but may compromise corrosion protection in certain applications. The choice between tinplate and tin-free steel hinges on balancing upfront manufacturing costs against the specific durability and safety requirements of the end product.

Environmental Impact and Sustainability

Tinplate offers enhanced corrosion resistance due to its tin coating, but the environmental impact includes the energy-intensive tin mining and refining processes. Tin-free steel, coated with chromium or other alternatives, reduces reliance on tin, lowering associated mining impacts and promoting resource efficiency. Both materials require careful assessment of life-cycle impacts to optimize sustainability in packaging and industrial applications.

Advantages and Limitations of Tinplate

Tinplate offers superior corrosion resistance due to its protective tin coating, making it ideal for food and beverage packaging where preserving product integrity is crucial. Its excellent solderability enhances manufacturing efficiency in applications requiring tight seals, unlike tin-free steel, which relies on more complex coating processes. However, tinplate tends to be more expensive and less environmentally friendly compared to tin-free steel, which utilizes chromium or organic coatings to reduce cost and ecological impact.

Choosing Between Tinplate and Tin-Free Steel

Choosing between tinplate and tin-free steel depends largely on corrosion resistance requirements and cost-effectiveness. Tinplate offers superior corrosion protection due to its thin tin coating, making it ideal for food and beverage packaging, while tin-free steel provides better weldability and cost savings in applications where corrosion is less critical. Assessing the specific application environment and performance needs ensures optimal material selection.

tinplate vs tin-free steel Infographic

materialdif.com

materialdif.com