The tin oxide layer provides enhanced corrosion resistance and electrical insulation compared to the metallic tin layer, which is more conductive but prone to oxidation and degradation over time. The oxide layer forms naturally on metallic tin surfaces, acting as a protective barrier that prevents further oxidation and extends the lifespan of tin-coated components. In electronic applications, controlling the balance between the tin oxide and metallic tin layers is essential to optimize performance, durability, and reliability.

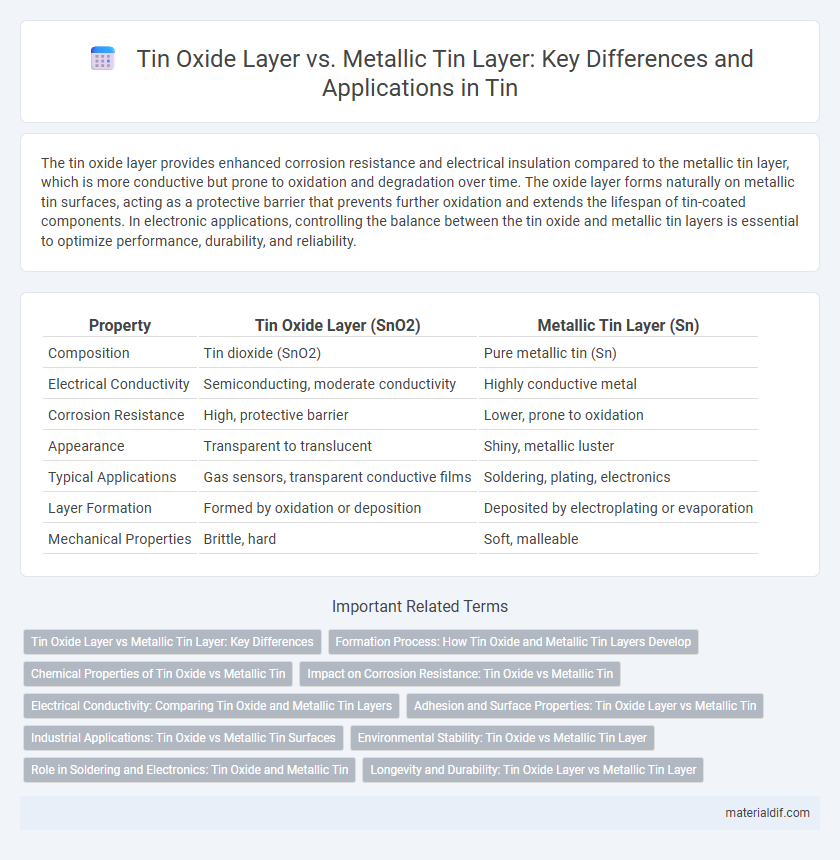

Table of Comparison

| Property | Tin Oxide Layer (SnO2) | Metallic Tin Layer (Sn) |

|---|---|---|

| Composition | Tin dioxide (SnO2) | Pure metallic tin (Sn) |

| Electrical Conductivity | Semiconducting, moderate conductivity | Highly conductive metal |

| Corrosion Resistance | High, protective barrier | Lower, prone to oxidation |

| Appearance | Transparent to translucent | Shiny, metallic luster |

| Typical Applications | Gas sensors, transparent conductive films | Soldering, plating, electronics |

| Layer Formation | Formed by oxidation or deposition | Deposited by electroplating or evaporation |

| Mechanical Properties | Brittle, hard | Soft, malleable |

Tin Oxide Layer vs Metallic Tin Layer: Key Differences

The tin oxide layer forms naturally on the surface of metallic tin when exposed to oxygen, providing a protective barrier against corrosion, while the metallic tin layer remains shiny and conductive but is more prone to oxidation and wear. Tin oxide is semiconductive and transparent, playing a vital role in electronic and sensor applications, whereas metallic tin is valued for its malleability, solderability, and low toxicity. The tin oxide layer significantly enhances durability and environmental resistance, distinguishing it from the more reactive and softer metallic tin surface.

Formation Process: How Tin Oxide and Metallic Tin Layers Develop

Tin oxide layers develop through the chemical reaction between metallic tin and oxygen in the environment, forming a thin, protective oxide film primarily composed of SnO2. This process, known as oxidation, occurs naturally at room temperature, accelerating with increased heat or exposure to moisture. In contrast, metallic tin layers are formed by direct deposition methods such as electroplating or physical vapor deposition, creating a uniform, pure tin surface without the presence of oxygen.

Chemical Properties of Tin Oxide vs Metallic Tin

Tin oxide exhibits higher chemical stability than metallic tin, resisting oxidation and corrosion under ambient conditions due to its passivating oxide layer. The metallic tin layer is more reactive, readily oxidizing when exposed to air, forming a protective tin oxide barrier that enhances durability. Tin oxide's semiconducting properties contrast with the metallic conductivity of tin, influencing their respective applications in electronics and coatings.

Impact on Corrosion Resistance: Tin Oxide vs Metallic Tin

The tin oxide layer offers superior corrosion resistance compared to metallic tin due to its stable, inert nature that forms a protective barrier against environmental agents. Metallic tin layers are more prone to corrosion as they can react with moisture and oxygen, leading to the formation of less uniform and less protective corrosion products. The protective effectiveness of the tin oxide layer significantly enhances the longevity and durability of tin-coated surfaces in harsh environments.

Electrical Conductivity: Comparing Tin Oxide and Metallic Tin Layers

Metallic tin exhibits high electrical conductivity due to its free electron availability in the metallic bond structure, making it ideal for electronic applications requiring efficient current flow. In contrast, the tin oxide layer, typically composed of SnO or SnO2, acts as a semiconductor with significantly lower electrical conductivity because of its wide bandgap and electron trapping at surface states. This distinction impacts their use in devices, where metallic tin layers are preferred for conductive pathways, whereas tin oxide layers serve in sensing or protective roles.

Adhesion and Surface Properties: Tin Oxide Layer vs Metallic Tin

Tin oxide layer exhibits superior adhesion properties compared to metallic tin due to its increased surface roughness and chemical stability, which enhance bonding with coatings and substrates. The oxide layer's hydrophilic surface improves wettability, promoting stronger intermolecular interactions in adhesive applications. Conversely, metallic tin's smoother surface and susceptibility to oxidation under environmental exposure result in weaker adhesion and less favorable surface properties.

Industrial Applications: Tin Oxide vs Metallic Tin Surfaces

Tin oxide layers exhibit superior corrosion resistance and electrical conductivity, making them ideal for use in sensors, transparent conductive coatings, and photovoltaic cells in industrial applications. Metallic tin layers provide excellent solderability and adhesion properties, widely utilized in electronics manufacturing for protective coatings and as a flux in soldering processes. The choice between tin oxide and metallic tin surfaces depends on the specific requirement for durability, conductivity, and chemical stability in various industrial environments.

Environmental Stability: Tin Oxide vs Metallic Tin Layer

Tin oxide layers exhibit superior environmental stability compared to metallic tin layers due to their inherent resistance to corrosion and oxidation. The tin oxide surface forms a passive barrier that prevents further degradation when exposed to moisture and atmospheric gases, enhancing durability in harsh conditions. In contrast, metallic tin layers are more susceptible to oxidation and subsequent tin whisker growth, leading to reduced lifespan and reliability in electronic and industrial applications.

Role in Soldering and Electronics: Tin Oxide and Metallic Tin

Tin oxide forms a naturally occurring passivation layer on metallic tin that significantly influences soldering quality and electronic reliability by preventing direct metal oxidation while affecting wettability. Metallic tin layers offer superior electrical conductivity and solderability, essential for creating strong, conductive joints in electronic components. The controlled presence of tin oxide is crucial to balance corrosion resistance and maintain optimal solder adhesion in circuit board manufacturing.

Longevity and Durability: Tin Oxide Layer vs Metallic Tin Layer

Tin oxide layer exhibits superior longevity and durability compared to metallic tin layer due to its enhanced resistance to corrosion and oxidation. The tin oxide acts as a protective barrier, preventing further degradation of the underlying metal, thereby extending the lifespan of tin-coated products. In contrast, metallic tin layer is more susceptible to wear and environmental factors, resulting in reduced durability over time.

Tin oxide layer vs metallic tin layer Infographic

materialdif.com

materialdif.com