Tin soldering involves melting a filler metal with a low melting point to join two metal surfaces without melting the base materials, creating a strong electrical and mechanical bond ideal for delicate electronics. Tin welding, on the other hand, melts both the filler and base materials, forming a robust, permanent joint suitable for heavy-duty applications but requiring higher temperatures and more skill. Choosing between tin soldering and tin welding depends on the project's strength requirements, heat tolerance, and precision needs.

Table of Comparison

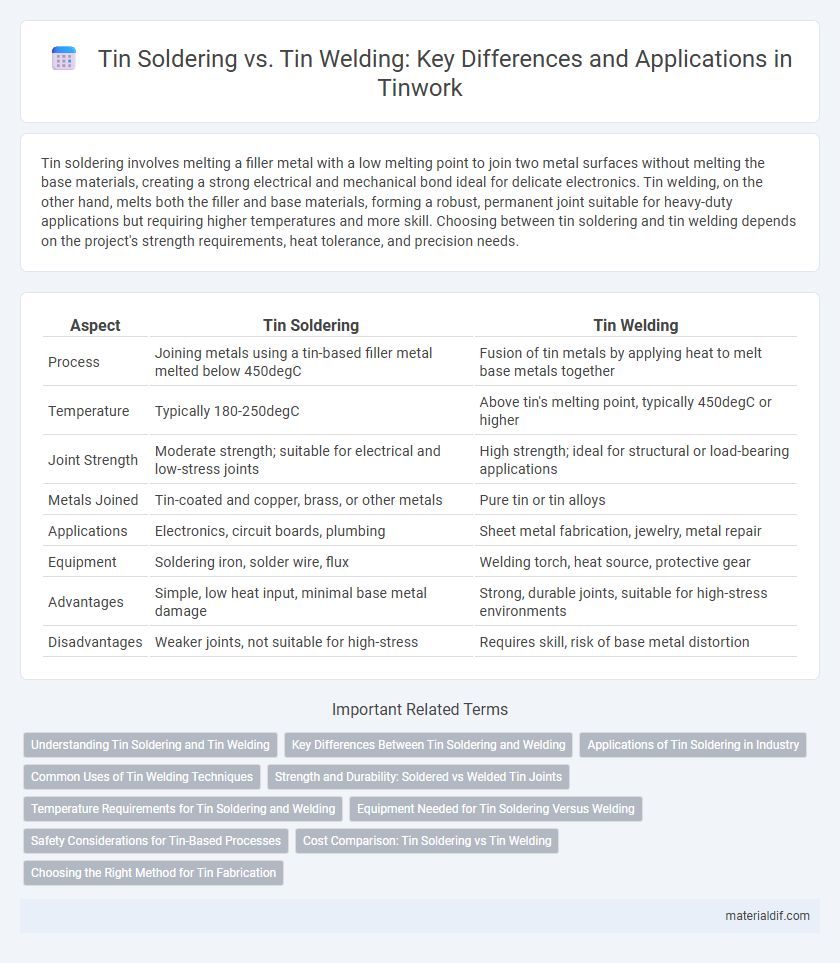

| Aspect | Tin Soldering | Tin Welding |

|---|---|---|

| Process | Joining metals using a tin-based filler metal melted below 450degC | Fusion of tin metals by applying heat to melt base metals together |

| Temperature | Typically 180-250degC | Above tin's melting point, typically 450degC or higher |

| Joint Strength | Moderate strength; suitable for electrical and low-stress joints | High strength; ideal for structural or load-bearing applications |

| Metals Joined | Tin-coated and copper, brass, or other metals | Pure tin or tin alloys |

| Applications | Electronics, circuit boards, plumbing | Sheet metal fabrication, jewelry, metal repair |

| Equipment | Soldering iron, solder wire, flux | Welding torch, heat source, protective gear |

| Advantages | Simple, low heat input, minimal base metal damage | Strong, durable joints, suitable for high-stress environments |

| Disadvantages | Weaker joints, not suitable for high-stress | Requires skill, risk of base metal distortion |

Understanding Tin Soldering and Tin Welding

Tin soldering involves joining metal components by melting a filler alloy with a low melting point, usually tin-based, to create a strong electrical and mechanical bond without melting the base metals. Tin welding, on the other hand, uses higher temperatures to fuse the base metals themselves, often in processes like TIG or MIG welding, resulting in a more robust and durable joint. Understanding the distinct melting points, temperature requirements, and joint applications is crucial for selecting tin soldering or tin welding in electronics, plumbing, or metal fabrication.

Key Differences Between Tin Soldering and Welding

Tin soldering joins metal components using a filler metal with a lower melting point than the base metals, creating a bond without melting the workpieces themselves. Tin welding involves melting the base metals together along with a filler metal, producing a stronger, more durable joint ideal for structural applications. Soldering is commonly used in electronics for delicate connections, whereas welding is preferred in heavy-duty manufacturing where mechanical strength is critical.

Applications of Tin Soldering in Industry

Tin soldering is widely used in electronics manufacturing for creating reliable electrical connections on circuit boards due to its excellent conductivity and low melting point. It is essential in the automotive and aerospace industries for assembling intricate components where precision and durability are critical. The medical device sector also relies on tin soldering to join delicate parts, ensuring biocompatibility and corrosion resistance.

Common Uses of Tin Welding Techniques

Tin welding techniques are commonly used in the electronics industry for creating strong, conductive joints in circuit boards and electrical connections. Unlike tin soldering, which relies on a filler metal to bond components, tin welding fuses tin components directly, ensuring enhanced mechanical strength and durability in applications like battery manufacturing and precision instrument assembly. These methods are also vital in the production of tin-based alloys and corrosion-resistant coatings in marine and automotive industries.

Strength and Durability: Soldered vs Welded Tin Joints

Soldered tin joints provide adequate strength for electrical connections but tend to be less durable under mechanical stress compared to welded joints. Tin welding creates metallurgical bonds that enhance structural integrity, resulting in stronger, more resilient joints suitable for load-bearing applications. The improved durability of welded tin joints makes them preferable in environments subject to vibration or thermal cycling.

Temperature Requirements for Tin Soldering and Welding

Tin soldering typically requires temperatures between 180degC to 250degC, allowing molten solder to bond metals without melting the base materials. Tin welding, specifically brazing or fusion welding, demands significantly higher temperatures, often exceeding 500degC to ensure proper melting and fusion of tin alloys with the workpieces. Controlling temperature precisely is crucial in both processes to maintain joint integrity and avoid damage to sensitive components.

Equipment Needed for Tin Soldering Versus Welding

Tin soldering requires a soldering iron or soldering station, along with solder wire containing tin and flux to ensure proper adhesion and electrical conductivity. Tin welding, often referred to as tin brazing or fusion welding, demands more advanced equipment such as TIG or MIG welders with precise temperature control to melt and fuse tin-based materials. The difference in equipment reflects the lower temperature and simpler technique of soldering compared to the high-heat, intensive process of welding.

Safety Considerations for Tin-Based Processes

Tin soldering involves melting a low-temperature alloy to join components, producing minimal fumes and posing lower burn risks compared to tin welding. Tin welding requires higher temperatures, increasing exposure to hazardous fumes, intense heat, and potential for molten metal splatter, demanding advanced protective gear and ventilation. Proper safety measures, including the use of fume extractors, heat-resistant gloves, and eye protection, are essential to mitigate risks associated with tin-based joining processes.

Cost Comparison: Tin Soldering vs Tin Welding

Tin soldering generally incurs lower costs due to its use of low-temperature processes and less specialized equipment, making it ideal for small-scale or electronic applications. Tin welding demands higher initial investment in machinery and energy consumption, but offers stronger joints suited for heavy-duty industrial uses. Evaluating the total cost of ownership involves considering material expenses, labor intensity, and application-specific requirements between soldering and welding techniques.

Choosing the Right Method for Tin Fabrication

Choosing the right method for tin fabrication depends on the specific application requirements and material properties. Tin soldering offers precision and is ideal for delicate electronic components due to its low melting point and excellent electrical conductivity. Tin welding, on the other hand, provides stronger mechanical bonds suited for structural applications where durability and heat resistance are critical.

Tin soldering vs Tin welding Infographic

materialdif.com

materialdif.com