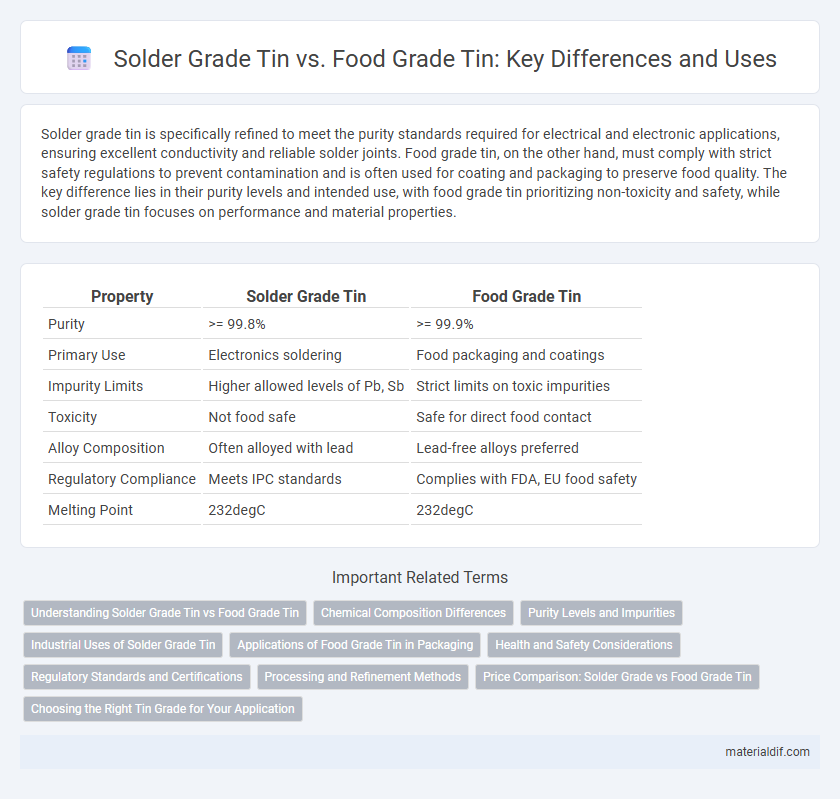

Solder grade tin is specifically refined to meet the purity standards required for electrical and electronic applications, ensuring excellent conductivity and reliable solder joints. Food grade tin, on the other hand, must comply with strict safety regulations to prevent contamination and is often used for coating and packaging to preserve food quality. The key difference lies in their purity levels and intended use, with food grade tin prioritizing non-toxicity and safety, while solder grade tin focuses on performance and material properties.

Table of Comparison

| Property | Solder Grade Tin | Food Grade Tin |

|---|---|---|

| Purity | >= 99.8% | >= 99.9% |

| Primary Use | Electronics soldering | Food packaging and coatings |

| Impurity Limits | Higher allowed levels of Pb, Sb | Strict limits on toxic impurities |

| Toxicity | Not food safe | Safe for direct food contact |

| Alloy Composition | Often alloyed with lead | Lead-free alloys preferred |

| Regulatory Compliance | Meets IPC standards | Complies with FDA, EU food safety |

| Melting Point | 232degC | 232degC |

Understanding Solder Grade Tin vs Food Grade Tin

Solder grade tin is characterized by its high purity and specific alloy composition tailored for optimal melting point and electrical conductivity, making it ideal for electronic soldering applications. Food grade tin, however, meets stringent safety standards to prevent contamination, ensuring it is non-toxic and safe for direct contact with food products or packaging. Understanding the differences between solder grade and food grade tin is crucial for selecting the appropriate type based on industry-specific requirements and regulatory compliance.

Chemical Composition Differences

Solder grade tin typically contains higher purity levels with minimal alloying elements, emphasizing reduced impurities like lead, silver, or copper to ensure optimal melting properties and electrical conductivity. Food grade tin demands stricter chemical composition controls, limiting toxic metals such as lead, cadmium, or arsenic to meet health and safety standards for food contact materials. The distinct chemical composition differences between solder and food grade tin directly affect their respective applications, safety, and performance characteristics.

Purity Levels and Impurities

Solder grade tin typically contains 99.3% to 99.8% purity with controlled trace impurities such as lead, copper, and bismuth, ensuring optimal melting properties and electrical conductivity for electronics. Food grade tin requires a higher purity level of 99.99% or greater, minimizing toxic impurities like lead and antimony to guarantee safety for food contact applications. The difference in impurity specifications directly impacts the suitability of tin for either soldering or food packaging industries.

Industrial Uses of Solder Grade Tin

Solder grade tin is primarily utilized in the electronics industry for manufacturing solder alloys due to its high purity and excellent melting properties, ensuring reliable electrical connections. Unlike food grade tin, which meets stringent safety standards for packaging and food contact applications, solder grade tin is optimized for performance in industrial soldering processes, including circuit board assembly and component bonding. Its industrial use extends to electronics manufacturing, where precise wettability and thermal conductivity are critical for producing durable and efficient electronic devices.

Applications of Food Grade Tin in Packaging

Food grade tin is primarily used in packaging applications such as food cans, beverage containers, and foil wrappers due to its non-toxic properties and excellent corrosion resistance. Unlike solder grade tin, which contains impurities suitable for electronic soldering, food grade tin meets strict safety standards to prevent contamination of food products. The protective tin coating extends shelf life and maintains product integrity by preventing metal corrosion and flavor alteration.

Health and Safety Considerations

Solder grade tin contains flux residues and impurities that may release harmful substances when heated, posing health risks through inhalation or skin contact during soldering processes. Food grade tin is purified and tested to meet strict safety standards, ensuring it does not leach toxic elements into food or beverages, thus preventing contamination and foodborne illnesses. Choosing food grade tin for applications involving direct contact with consumables is critical to maintaining safety and compliance with health regulations.

Regulatory Standards and Certifications

Solder grade tin complies with standards such as IPC J-STD-006 and ASTM B32, ensuring its purity and performance for electronic soldering applications. Food grade tin meets stringent regulatory certifications like FDA 21 CFR and EU Regulation No. 1935/2004, guaranteeing it is safe for direct contact with food and beverages. Compliance with these specific standards ensures traceability, purity levels, and the absence of harmful contaminants tailored to each industry's safety requirements.

Processing and Refinement Methods

Solder grade tin undergoes rigorous refining processes including electrolysis and chemical treatments to achieve high purity levels, typically above 99.8%, ensuring optimal electrical conductivity and solderability. Food grade tin is processed with stringent controls to meet FDA and EU standards, often involving advanced filtration and refining techniques to eliminate toxic impurities and contaminants, guaranteeing safety for direct food contact. The differentiation in refinement focuses on purity standards and contamination controls specific to industrial soldering versus food safety applications.

Price Comparison: Solder Grade vs Food Grade Tin

Solder grade tin typically costs less than food grade tin due to lower purity requirements and fewer processing standards. Food grade tin demands stringent quality control and certifications to ensure safety for human consumption, driving up its production costs. Price differences can range from 20% to 50% higher for food grade tin compared to solder grade, depending on supply chain factors and regulatory compliance.

Choosing the Right Tin Grade for Your Application

Selecting the appropriate tin grade is crucial for optimizing performance and safety in specific applications. Solder grade tin is specially refined to ensure high purity and excellent wetting properties, making it ideal for electronic soldering and precision joining tasks. Food grade tin undergoes stringent purity standards and is certified safe for direct contact with food, preventing contamination in packaging or food processing environments.

Solder grade tin vs Food grade tin Infographic

materialdif.com

materialdif.com